Honda to Begin Sales through Gas Utilities of All-New Ultra-Efficient Household Gas Engine Cogeneration Unit Featuring World’s Most Compact Design

May 23, 2011, Japan

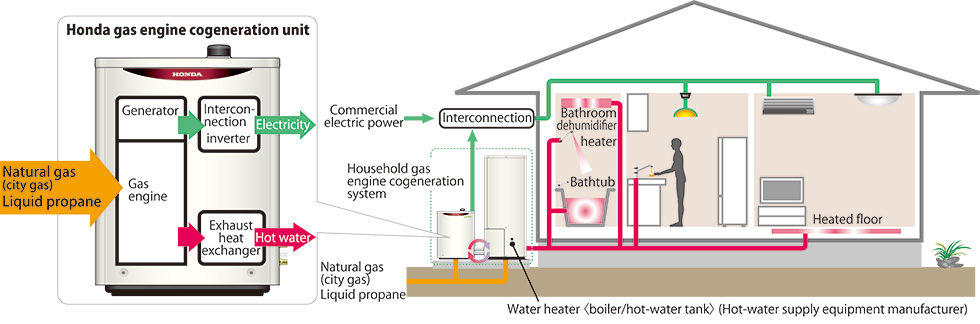

TOKYO, Japan, May 23, 2011 - Honda Motor Co., Ltd. announced it would begin sales this month of an all-new ultra-efficient household MCHP (micro combined heat and power) gas engine cogeneration unit through gas utilities across Japan. Building on its well-received predecessors with a completely new design, MCHP1.0K2 serves as the core unit in the household cogeneration system ECOWILL, burning natural or liquid propane gas to generate electricity and heat water simultaneously for exceptionally high energy efficiency.

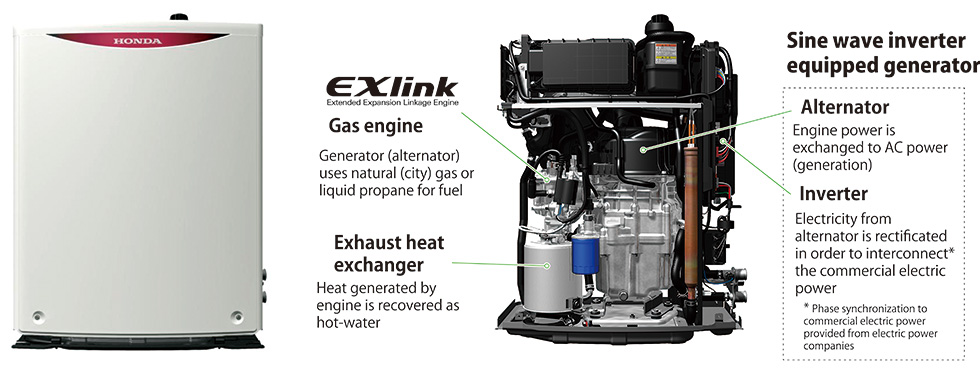

MCHP1.0K2 features Honda's EXlink (Extended Expansion Linkage Engine),*1 whose expansion stroke is longer than its intake stroke, resulting in a high expansion ratio for greatly increased thermal efficiency and fuel efficiency. Based on EXlink and Honda's original sine wave inverter power generation technology, MCHP1.0K2 offers power generation efficiency of 26.3%,*2 as compared to 22.5% for the previous model. In addition, thanks to its high-efficiency heat circulation system, which thoroughly recovers the heat the engine generates, MCHP1.0K2 offers combined power and heat generation efficiency of 92.0%,*3 as compared to 85.5% for the previous model. By virtue of these enhancements, as part of a household cogeneration system that includes a water heater, MCHP1.0K2 can help a household save ¥50,000 in power and heating costs per year.*4 MCHP1.0K2 also features the world's most compact design for a cogeneration unit,*5 making it easy to install in a wide variety of homes.

In 2003, Honda began sales of its first compact household cogeneration unit, which combined a gas engine with Honda's original sine wave inverter power generation technology. Under the brand name ECOWILL, cogeneration systems composed of the Honda cogeneration unit and a water heater utilizing exhaust heat have been sold by gas utilities across Japan and installed in some 108,000 households.*6

With gas-powered household cogeneration units and thin-film solar panels as featured products, Honda's home power generation business supports ecological household energy production and consumption, thereby helping to realize the low-carbon society of the future.

- *1"EXlink," short for Extended Expansion Linkage Engine, is a trademark of Honda Motor Co., Ltd.

- *2Lower heating value (LHV) calculation

- *3LHV figure calculated with MCHP1.0K2 long-life coolant temperature at 75 ℃

- *4As compared to a household using electricity generated via thermal power generation and a water heater burning natural gas (13A); gas utility calculations

- *5Among gas engine and fuel cell cogeneration units; Honda calculations

- *6Honda calculations as of March 31, 2011

MCHP1.0K2

household gas engine cogeneration unit

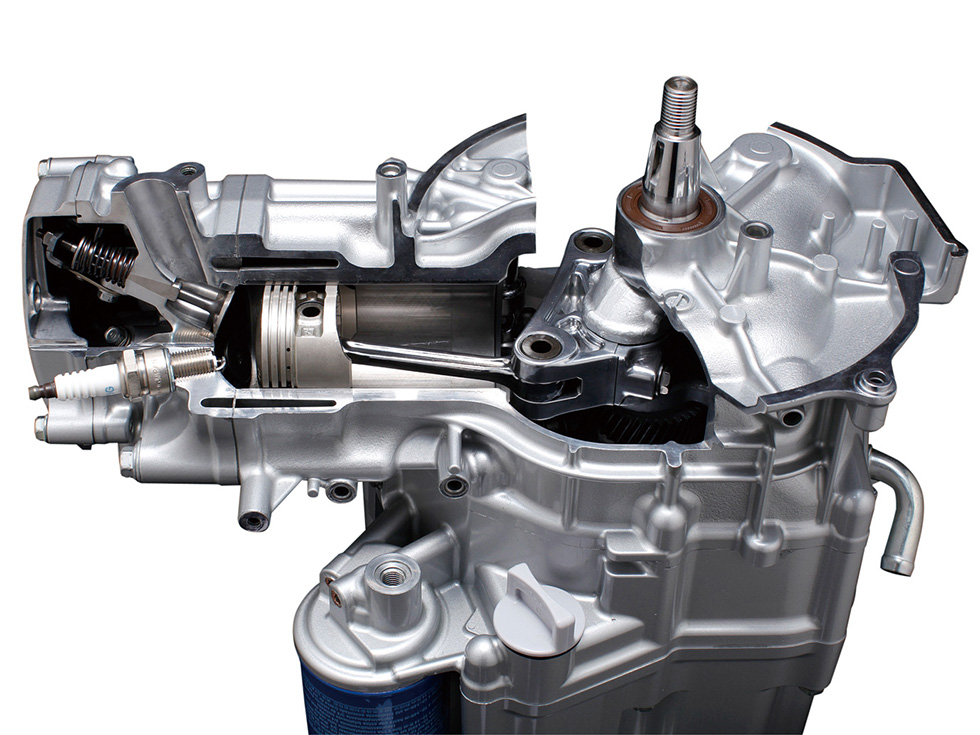

EXlink Extended Expansion Linkage Engine

(cross section photo)

Interior structure of MCHP1.0K2

| Main specifications of MCHP1.0K2 household gase engine cogeneration unit | |

| Fuel: | Natural gas, liquid propane |

| Engine type: | 4-stroke liquid-cooled single-cylinder OHV |

| Displacement: | Intake stroke volume: 110 cm3; exhaust stroke volume: 163 cm3 |

| Electricity generation type: | Multipolar sine wave inverter power generation |

| Electrical output: | 1.0 kW (AC 100/200 V) |

| Heat output: | 2.5 kW |

| Weight (installed): | 71 kg |

| Dimensions: | Height 750 mm × width 580 mm × depth 298 mm (excluding protruding parts) |

MCHP1.0K2 system diagram

Key features of MCHP1.0K2 household cogeneration unit

All-new compact, high-efficiency EXlink offering greatly reduced fuel consumption

- Comprising a trigonal link, swing rod and eccentric shaft, the new extended expansion linkage structure of the engine makes possible an extra-long expansion stroke, which is the piston stroke that produces power. By compressing a smaller volume of fuel and air and allowing the air-fuel mixture to combust and expand into a greater volume, an expansion ratio 1.4 times greater than the compression ratio is achieved, and a greater amount of combustion energy can be used to perform work. In addition, the shorter intake stroke helps reduce pumping loss, which is the energy lost from moving air into an engine's cylinder during intake. Thanks to the higher expansion ratio, thermal efficiency is substantially higher than in an engine in which the expansion and compression ratios are equal. As a result, MCHP1.0K2 offers fuel consumption that is approximately 15% lower than that of the preceding model.

High power generation efficiency and heat recovery rate

- MCHP1.0K2 offers ideal household electrical output of 1.0 kW, heat output of 2.5 kW and combined power and heat generation efficiency of 92.0%. Power generation efficiency is 26.3%, as compared to 22.5% for the preceding model.

- In the alternator, the position of the rotor magnet and the position and number of the stator slots have been optimized to minimize eddy currents and prevent energy losses.

- The inverter features simplified circuits with highly integrated devices to reduce electrical resistance.

- When the electric output of the unit exceeds the electrical load usable by the household, the unit enters load optimization mode, using the excess electricity to generate additional heat.

- By integrating the heat exchanger with the catalytic converter and enhancing the cooling system design, a heat recovery rate of 65.7% has been attained. During combustion, exhaust heat and heat in the body of the unit is recovered at the high temperature of 75 ℃, making possible the efficient production of hot water for bathing, heated floors and other uses. Highly energy-efficient and economical, MCHP1.0K2 offers outstanding combined power and heat generation efficiency of 92.0%, which means that 92% of the energy contained in the natural gas primary energy source is put to use. As compared to a household using electricity generated via thermal power generation and a water heater burning natural gas, a household using a cogeneration system that includes MCHP1.0K2 will generate approximately 39% less CO2. *7

- *7As calculated with CO2 emission coefficients of 0.69 kg per kWh of electricity (from "Midterm Summary" of Objectives Attainment Scenario Subcommittee, Earth Environment Sectional Meeting, Central Environment Council, July 2001) and 2.29 kg per cubic meter of 13A gas used (gas utility calculations)

High-efficiency packaging

- The shorter intake stroke of the high-expansion ratio engine helps make possible a smaller intake system and a more lightweight and compact overall design. The exclusive vertical engine layout featuring a vertical crankshaft, horizontal cylinder and integrated oil tank helps further minimize the weight and size of the unit.

- Thanks to the integration of parts and a variety of layout enhancements, MCHP1.0K2 has a 33% lower volume and weighs 11 kg less than the preceding model.

Low vibration and noise

- An enhanced lower engine mount structure and other design enhancements help reduce pulsation and air channel noise in the intake and exhaust systems.

- The optimized placement of sound-proofing materials result in low vibration and noise equivalent to that of an air conditioner outdoor unit (43 dB(A)).*8

- *8As measured in an anechoic chamber in accordance with the JIS (Japanese Industrial Standards) method for measuring gas engine heat pump (GHP) noise

Easy installation and maintenance

- The depth of the unit is only 298 mm - 82 mm less than that of the preceding unit. In addition, the unit may be accessed from the side to perform maintenance work. With full allowance for maintenance space, a space only 650 mm wide may accommodate the unit. Thanks to its compact design, MCHP1.0K2 may be installed in homes of many different sizes and shapes.

- During setup of the unit for power grid interconnection, the ECU (Electronic Control Unit) control panel allows for the input of settings provided by the utility without the use of maintenance tools, making installation easier. The control panel can also display the time elapsed since maintenance and a variety of error codes.

Outstanding reliability

- Long-life spark plugs and a large-capacity oil tank allow for a maintenance interval of 6,000 hours of use or three years, whichever comes first.

- A grid monitoring system with dual power outage detection function constantly monitors the power grid voltage waveform to detect outages and safely shut down the system should power be lost.