Honda Creates a New IMA System to be Installed in the All-New Civic Hybrid

September 4, 2001, Japan

Tokyo, September 4, 2001 --- Honda Motor Co., Ltd. today announced new technological advancements that further improve the efficiency of its IMA (Integrated Motor Assist) System, a unique hybrid system that significantly contributes to higher fuel efficiency. An all-new hybrid car called the Civic Hybrid, to be released this fall, will employ this latest hybrid technology.

The engine in the new IMA System will incorporate Honda's state-of-the-art i-DSI*1lean-burn combustion technology, along with a newly-developed cylinder idling system that adapts Honda's VTEC variable valve control system to significantly increase the amount of electrical energy recovered during deceleration. These new features contribute to improved fuel economy.

Other technological advances provide increases in both motor assist system performance and Power Control Unit (PCU) efficiency. Combined with the Honda Multimatic S continuously variable automatic transmission, Athis new system achieves a combination of excellent drivability and superb gas mileage. At over 29km/L*2, this vehicle is at the top of its class for 5-passenger, mass-produced gasoline-engine vehicles, and meets fuel consumption standards for the year 2012. It also runs cleanly enough to be recognized by the Japanese Ministry of Transport as an Ultra Low-Emissions Vehicle.

- *1DSI:Dual and Sequential Ignition

- *2According to in-house testing (10-15 mode)

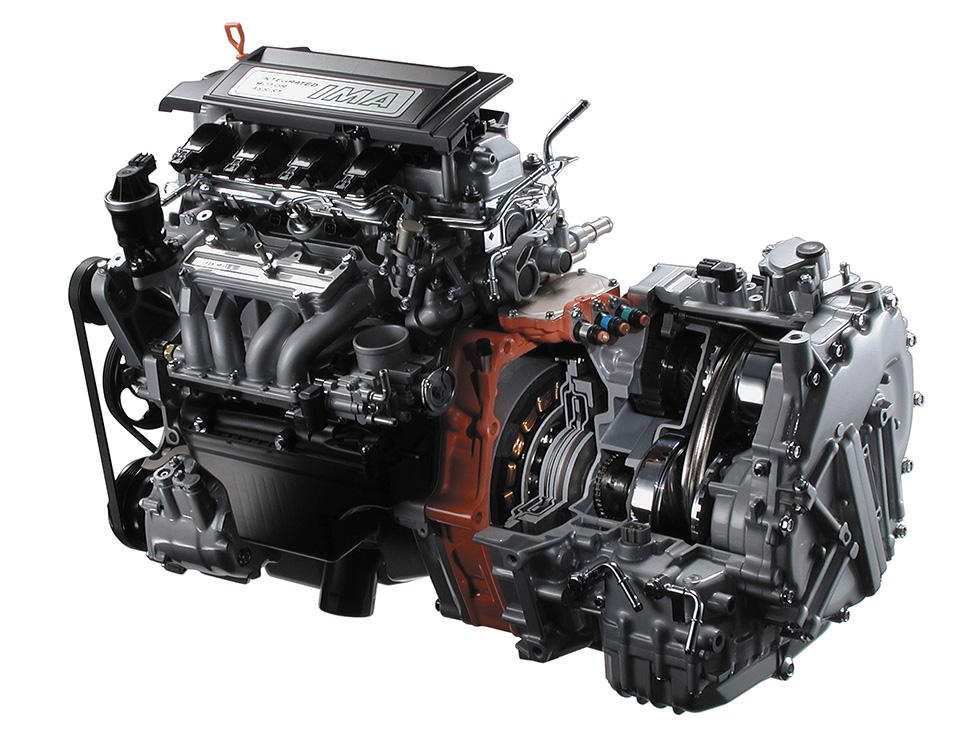

New IMA System (cut-away model)

Features of the New IMA System

The new IMA System employs a gasoline engine as its main power source, assisted by an electric motor as the need arises. It offers improved efficiency over the previous IMA System on which its design is based. The Insight, which was equipped with the previous IMA system, boasted the highest fuel economy in the world for a production vehicle.

During acceleration and other times of heavy engine load, the motor assist system contributes considerable torque, resulting in both lower fuel consumption and powerful acceleration. At cruising speeds when engine load is lower, the motor assist system shuts down. The newly developed 1.3-liter i-DSI lean-burn engine achieves the highest standard of fuel economy in the world.

During deceleration, the motor converts the dissipated energy into electricity (regenerative braking). The newly developed cylinder idling system reduces engine resistance during deceleration-formerly a problem with regenerative braking-greatly improving the vehicle's electrical regenerative efficiency.

When stopping, at traffic lights for example, the engine shuts off automatically, then restarts immediately when the driver steps on the accelerator pedal. This auto idle stop system contributes to both greater fuel efficiency and lower emissions.

New 1.3-liter i-DSI Lean Burn Engine

- The engine features the basic i-DSI configuration of two spark plugs per cylinder. This allows the fuel-air mixture to be made even leaner, for improved fuel economy.

- The rocker arms that open and close the intake and exhaust valves are configured for dual operation in either valve-lift mode or idle mode. Normally, they are engaged via a synchronizing piston. During deceleration, the synchro piston is housed inside the idle-mode rocker arm, disengaging the lift-mode rocker arm so that the valve remains at rest, effectively sealing off the cylinder. Three of the four cylinders can be shut down, achieving 50% less engine resistance during deceleration than the present IMA System.

- Also featured are both a 900-cell three-stage catalytic converter and a lean burn-compatible absorption-type NOx catalytic converter. The result is a clean-burning engine that meets the Japanese Transport Ministry's exhaust-gas emissions standards for ultra-low emissions vehicles.

New Motor Assist System

- The motor assist system is composed of an ultra-thin DC brushless motor, a Nickel Metal Hydride battery, and a Power Control Unit (PCU). The new system employs a higher-output motor, a more efficient battery, and a lighter, more compact PCU that results in greater packaging freedom.

- Improvements to the internal magnetic coils of the ultra-thin DC brushless motor, which boasts the world's highest output density and practical efficiency, achieve 30% greater assisting and regenerative torque than the previous model, without increasing the size. A sintering diffusion bonding process is used to firmly fuse different metals together, allowing the most appropriate materials to be used in construction of the rotor to meet the different demand criteria for its inner section, which transmits torque, and its outer section, which is in contact with the magnetic coils. Strengthening the section that transmits the torque and increasing the magnetic-flux density results in higher torque output.

- The inverter and the pre-driver have been combined, reducing the weight of the PCU by around 30%, and its volume by around 40% in comparison to the present system.

- The efficiency of the battery modules has been increased, resulting in reduced energy losses. The battery's storage box and peripheral equipment have been made more compact, for an approximate 30% reduction in volume.

- The lighter, more compact, more efficient PCU and battery have been integrated into a single Intelligent Power Unit (IPU) that can be stored behind the rear seat of a passenger sedan.

Integrating the IPU allows the two cooling circuits previously used to be combined into one. Total volume of the PCU and battery has been reduced by 50%.