Factory-installed tires on new motorcycles are called OE, or original equipment, tires.

There is quite a profound reason for their existence. In this article, we, as a motorcycle manufacturer, will explain why these OE tires are so important.

Index

1. OE Tires: Born with New Vehicles

Original equipment (OE) tires installed on new bikes are closely connected with the bike's development.

The vehicle manufacturer selects OE tires it believes has characteristics best suited to its bike, pairing these tires to its bikes from the design and development stage.

While not everything is exclusively tuned for this pairing, the structure and compound are often tuned according to the bike's required performance and characteristics, resulting in dedicated design and specifications.

For example, grip is important for sports models, while wear resistance and comfort are important for touring models. Even though the external appearance of the tire has the same pattern as that of commercial tires, they are different internally, and each manufacturer has its own unique method of identification.

(“U” identifier next to the Roadsport2 pattern name)

2. Tested Repeatedly on Actual Bikes from Development Stages

OE tires are tuned not only based on theory from design drawings, but also through repeated testing on actual bikes. Driving evaluations on actual vehicles are essential in order to focus on performance that can be perceived while riding, such as front/rear balance, handling, and ground contact during acceleration and deceleration.

Evaluations are conducted not only on regular paved surfaces, but also on wet surfaces in anticipation of rainy conditions and on courses that simulate various road surfaces from around the world. This test is repeated many times until it meets the target performance.

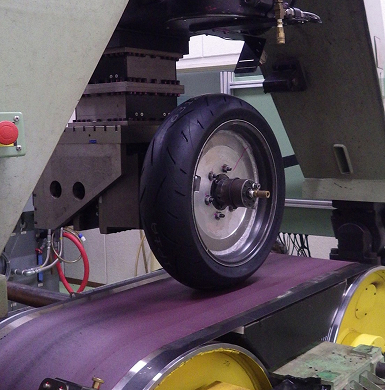

However, development time is limited. Some tire manufacturers use large-scale testing facilities to develop tires efficiently by combining quantitative data and measurement results, rather than just conducting quality evaluations of prototype tires.

*Tire quality evaluation: Evaluates whether the dimensions of each component of the tire are as designed

Tire property tester

Rigidity tester

3. Legally Compliant for Peace of Mind

OE tires are used in bikes after undergoing various quality tests in order to comply with the regulations of each country.

Examples of typical regulation-compliant quality tests

・ FMVSS119 plunger test: A test to measure the internal strength of a tire by pressing a plunger against it.

・ UNR75 high-speed endurance test: Evaluates the ability to withstand high-speed driving.

Furthermore, for tires with high performance requirements, we not only meet regulatory standards, but we also conduct rigorous evaluations to make sure they are safe and reliable.

High-speed endurance test

Example of results of high-speed endurance

test to confirm breakage

4. Summary

Not every tire manufacturer has their products selected as OE tires.

These tires require adaptability to bike characteristics, development capability, a quality assurance system, supply system, and more.

Selecting OE tires requires reliability to meet high and demanding standards.

After joint development with tire manufacturers, we conduct several test runs and endurance tests, and only tires that meet strict selection criteria become OE tires to be installed to our bikes.

*Interviewed at: Sumitomo Rubber Industries, Ltd.