The ZE Engine (GX110 / 140 / 240 / 270 / 340 Series) / 1983

The Reality: Learning from Damaged Parts

Traveling upstream on the Menam (Chao Phraya) River past Bangkok reveals many "longtails" floating on Thailand's giant river. Longtails are small boats equipped with general purpose engines instead of outboard marine engines. This type of engine has a long propeller shaft that sticks out of the boat, resembling a dragonfly's tail. The boat is called a "longtail" because of this propeller shaft. Longtails are indispensable to the lives of people in Thailand, as well as to those in other developing nations in Southeast Asia. They are an important means of livelihood, facilitating transportation and fishing.

The longtail's engine operates with its body kept at an angle. Understanding the actual conditions of engine use had led to many of the features employed in the ZE engine. (Photographed in Indonesia)

"I found one! Let's go after that boat!"

Running ahead in the direction the voice had indicated was a longtail with an engine painted red and white. That particular color combination meant that it was an ME, the engine developed by Honda in 1977. The voice came from Yoshinobu Yamaguchi, who had been involved in the engine's testing. He and his colleagues wanted to verify how their engine was being used, and whether or not there were any problems regarding its real world use. They were chasing the boat ahead of them, searching for the kind of information they could not obtain simply by analyzing data in the cold environs of a distant office. They had managed to make time during their business trip in order to travel up the Menam, all the while hoping they would make contact with users and obtain some feedback.

General purpose engines are used in a number of ways, meaning one cannot develop a truly applicable product unless its conditions of use are understood. Therefore, the ME engine's notable success was largely attributable to the efforts of a development staff that had traveled the world identifying its requirements. They had the ability to see things and analyze them from the standpoint of engineering. For example, during a visit to a retailer the staff would go to the repair area and search the drums and other waste containers filled with damaged engine parts. It was a noisy process going through the parts, but in the process they could usually find worn cylinders and other clues. They would examine the oil deposits and find them to be filled with dust, proving there was a need to improve the air cleaner. In this way, every damaged part would tell its own story, often inferring a great deal about the harshness of use and the environment surrounding it. Ultimately, improvements would be made and ideas for new models proposed. This indeed symbolizes the Honda's principle of "focusing on real-world, on-site operations while facing up to the challenges inherent in reaching a goal."

"It didn't matter that we couldn't speak the language," said Yamaguchi. "As engineers we knew what kinds of data we'd need to apply in our workstations. We simply had to watch the users as they brought their products in for repair. That way we could find out more about the problems they'd been having."

Yamaguchi held firmly to the belief that such a strategy was of paramount importance in the development of reliable, high-performance products. Each time he went abroad, he would make time available in which to study the market. He would journey through the dry cattle lands of Australia, visit busy rental shops in America, and wade into the rice paddies of Thailand. The world market was to Yamaguchi the very soul of research, and knowing something of his customers and their lives kindled in him a sense of ambition. It was the desire to build an engine that would satisfy the needs of each customer who bought it.

When the Customer Says, "It Has to Be Honda"

Honda's ME engines proved popular throughout Southeast Asia, particularly in Thailand, where the demand was so strong that some retailers stopped displaying the engine because it would easily sell right out of the box. In fact, other manufacturers began finishing their products in red and white, because so many customers had specified "that red-and-white engine." However, it was not all roses for Honda. Out in the OEM market there were harsher realities to face.

The chassis-only tillers displayed at a retailer in Thailand. They are sold after being fitted with a separate, general purpose engine. Engines lacking installation compatibility are shut out of the retail sales channel.

The ME engine, developed through a series of efforts intended to reduce its cost by half, was as much as 2,000 yen cheaper than other manufacturers' engines of the same class. The ME engine was also 10 percent cheaper than its rivals in the OEM market, where the price would vary according to the number of units ordered. Therefore, cost was the key selling point for general purpose engines, and everyone knew Honda, with its lower price point, had the advantage. As it turned out, though, a low price didn't benefit the company to the expected degree.

Yamaguchi himself also visited OEM companies in Japan, where he promoted the ME engine. However, he was on the receiving end of critical comments:

"Although the engine itself costs less," they would say, "it costs extra to install and test it in our machine. It also requires a lot of difficult, cumbersome work. We don't think we want your engine."

Others would say things like, "It's a great-looking product, but we cannot adopt it unless your products are designed to fit our machines with the absolute assurance there won't be any problems. That's what the other suppliers do."

Yamaguchi gave demonstrations amply proving the engine's performance, sometimes out in the snow and bitter cold. However, following a series of disappointments his once-abundant optimism had been left shattered in pieces. One comment he received from a manufacturer of construction machinery was a particularly heavy blow:

"Mr. Yamaguchi, it's true that a savings of 2,000 yen would add to our company's profits. However this saving wouldn't be passed on to the completed machines as a significant price advantage in the market. In other words, there would be no benefit for the customer who used the product to choose one with the Honda engine."

Those words had come as a shock to Yamaguchi. After all, he and his colleagues had studied regional markets with their own eyes, observing engine uses and identifying problems. He was confident they had created a price-competitive engine that met all the requirements.

"Our goal is to create an engine that satisfies the customers who use it," Yamaguchi would say. "I want to hear them say, 'It has to be Honda' the next time they purchase an engine. This feeling is shared by all the engineers at Honda."

This man, though, was saying their effort was not being appreciated by the consuming public. Moreover, price had nothing to do with it. As Yamaguchi said, "It was a tremendous shock to me as an engineer."

The ME engine was undoubtedly a success, though, and because of that Honda was able to compete with other manufacturers who were active in the same arena. Although their comments were rather harsh, those OEM companies would not have even looked at Honda engines if it had not been for the ME model. Still, Honda needed a decisive edge in order to lead the competition and make the customer say, "It has to be Honda."

One comment stood out in Yamaguchi's mind: "Don't depend on (price) difference alone, but make use of the product's uniqueness." This painful experience ultimately became the foundation for development of the ZE engine.

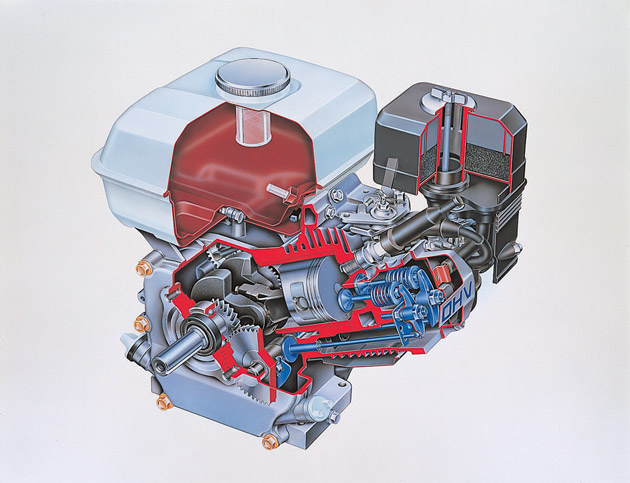

The Honda ZE engine series, featuring OHV+inclined cylinders

Initiating the ZE Project: From SV to OHV

Honda ordered the development of a consumer-oriented engine in October 1980 with the intention of having a successor to the popular ME model. When the decision was made, the ME's yearly sales volume was still under the 1 million mark, but it was only a matter of time before the figure would pass it. However, the ME engine had been developed for the industrial market, so in order to expand its overall market share for general purpose engines Honda had to gain a foothold in the consumer arena. To do this, the new engine's yearly sales target was to be three million units.

To develop a new engine that was small, economical and maintenance-free, Honda's development staff analyzed vast collections of data gathered from the many ME engine units that had found their way into the world. And with that analysis a research project was started with two possible directions, the first being a side-valve (SV) engine with smaller displacement but higher performance, and the second being an overhead valve (OHV) engine.

The oil crises of the 1970s had made society more conscious of the need to conserve energy resources, and through its ME experience Honda knew it had to find a decisive feature unavailable with competing engines. Accordingly, the research effort began to focus on a fuel-efficient, high-output OHV engine. In 1981, Honda officially decided to adopt the OHV design as the mainstay of its next-generation engine line. Research was specifically directed to identify a structure and concept suitable for lawnmowers and general purpose applications.

Honda's interest in lawn mowers reflected a desire to reach out to customers for power products in the U.S. With regard to lawnmowers, Honda's engines were already respected among professionals for their superior performance, even prior to the ME's introduction. However, to meet current expectations and build sales, the OHV configuration was absolutely necessary. Therefore, the ZE project began with a two-prong approach, aiming to develop the ZE01 general-purpose engine and the ZE5 for lawnmowers.

OHV: Benefits and Disadvantages

Most general purpose engines were in those days of the SV type. Accordingly, new OHV engines were expected to give the edge to Honda, since SV engines consumed more gasoline and oil, and were noisy and hot. In addition, they had shown themselves to be subject to problems in initial quality. The OHV configuration, on the other hand, was more powerful, economical, cleaner, quieter, and more durable. However, despite the OHV's obvious benefits, the SV configuration remained the mainstream in general purpose applications.

The reasons for that were as follows:

First, the OHV engine was larger because its valve had to be mounted above the cylinder. The OEM companies would not accept any engines exceeding their standard installation dimensions, which were for the most part based on SV engines. To find a market, a general purpose engine had to ensure "installation compatibility.

Second, the larger number of parts made the OHV heavier and more costly. Portability and economy are basic requirements in the world of general purpose engines. No matter how well one might perform, no engine would be accepted as a commercial product if the basic requirements - again, portability and economy - were not satisfied. For these reasons the OHV engine design had been studied by most manufacturers, but never seriously developed.

The ZE5 lawn mower engine would have a certain amount of latitude in dealing with these characteristics, because it was developed as part of a complete machine. However, the ZE01 general-purpose engine targeting OEM companies found itself up against a wall. The problems of size, weight, and cost necessitated engineering targets that had to be achieved in order to develop a successful product. Such problems also meant they would have to depart from common sense thinking with regard to general purpose engines.

Confidence in the Search for an Ideal Design

Two engines were developed under the ZE01 project heading - one with 3.5 horsepower and another with 5 horsepower - and each was to share parts with the other. Yamaguchi, now the project leader, wanted to reflect in the new engines everything he had learned from his own experience. He understood what the ME had failed to achieve, but he understood equally well the weakness of engines from other manufacturers. Further, he knew why the customers had not been satisfied. Therefore, he was confident the new OHV engines would solve the problems inherent in the previous models. He was willing to introduce various ideas, as long as they did not raise the cost, and in this task he applied himself through long hours at the drawing board.

Yamaguchi's initial challenge was engine size, since with a general purpose engine the fuel tank is normally found on top. However, with an SV engine the tank can be mounted directly to the body. Moreover, an OHV engine has its cylinder head and valves positioned between the body and tank, thus increasing the height of the engine assembly. Increased height means a higher center of gravity and more significant amounts of vibration. It also affects engine manageability when installed in a work machine. Detachment of the fuel tank requires an extra function in order to feed fuel to the engine. Thus, the tank should remain connected to the engine, ideally above the body. However, installation compatibility was the most important issue of all, and most companies were still loyal to SV engines. No matter how good the performance was, no OEM company would adopt an OHV engine if it meant a change in specifications. The Honda engine, which lacked installation compatibility, had already made that clear.

Yamaguchi solved this problem with the help of the ME engine. First, he drew an outline of an ME, then he tried to fit the OHV engine into it. After all, the ME's dimensions had been determined through intensive studies of installation compatibility. Thus, an OHV that could fit within the ME's dimensions would ensure installation compatibility. After drawing many designs with different cylinder positions, Yamaguchi finally came up with the idea of setting the cylinder at an incline.

The idea was not so convincing to other staff members, though. In fact, the ZE engine would not be the first Honda engine for which an inclined cylinder had been attempted. The G25 engine released in 1966 had adopted this design with a cylinder placed almost horizontally. However, that engine design was fraught with problems, including heat damage. The staff, who remembered the experience, was very skeptical. "We've already had enough anguish," they said. "Why the inclined cylinder now? What's wrong with the vertical layout?'

Yamaguchi was in fact involved with development of the G25 engine, so he knew well the struggles it had produced. "There was no meaning in developing OHV engines that couldn't promise installation compatibility," Yamaguchi recalled. "If the ideal design for a general purpose engine means an inclined cylinder, we must face the obstacles and overcome them. We had already had the facts of engineering. We couldn't afford to hesitate, now. We had to make the best use of that experience."

A series of long discussions took place, and through Yamaguchi's articulate passion, a consensus was finally found. Following the decision, the staff members visited farms in mountain areas in order to study how cultivators and other machines were used on the slopes and apply that data to laboratory tests. Consequently, the angle was set to 25 degrees to prevent the backflow of oil. With that, the inclined cylinder's specifications were at last determined.

A local market-compatibility test for the ZE Series model CX140, held in Thailand (Photograph on those days courtesy of Yoshinobu Yamaguchi)

Integrating Parts through Usage

The OHV configuration, while it offered key advantages, also necessitated more parts, a problem that was eventually solved through an exhaustive program of integration. For example, the fuel cock located between the fuel tank and carburetor serves the purpose of preventing fuel leaks during transportation and overhauling. With the ZE engine, the need for a separate fuel cock was eliminated through integration with the carburetor. Adopting the bonding technique of caulking three plates allowed the fuel tank to be mounted directly on the head, further contributing to a reduction in parts. As a result, the number of parts in the new OHV engine, which a normal design would have increased by about 20 percent, was reduced to a number even lower than found in the ME engine.

A key point in the reduction of parts, in addition to the effective ideas incorporated through new mechanisms, was that the development team had achieved such a thorough understanding of the ways general-purpose engines were used. They not only consolidated the parts from an engineering perspective, but also distinguished the necessary parts from unnecessary ones based on product usage. Their experience in field-testing had been put to maximum use. The 20 percent reduction in parts had undoubtedly led to a drop in cost, but more importantly doing so did not sacrifice the functionality of the engine. This was a real advantage for the ZE engine.

Various ideas had been adopted in order to make the OHV engine easier to handle, one such innovation being the mechanical decompression mechanism. An OHV engine offers a better compression ratio due to higher fuel-combustion efficiency. However, this leads to higher pressure, so greater force is required to start the engine. Therefore, a decompression mechanism was added in order to reduce the starting pressure. During the mechanism's development several different ideas were attempted and abandoned, since it was essential that the team avoid any patent infringements. Their effort finally led to the establishment of a proprietary Honda technology.

OHV + Inclined Cylinder as de facto Standard

The 3.5-hp GX110 engine and the 5-hp GX140 were released as ZE Series engines in January 1983, taking Honda's international competitors by surprise. The new engines offered all the advantages of OHV engines - namely, higher performance and better fuel economy - along with the added benefits of an inclined cylinder, such as a lower center of gravity and reduced vibration. Moreover, their compact size - 30 percent smaller than the target installation dimensions - enhanced design flexibility for the base machines in which they had been installed. For these reasons, the sales of ZE Series engines grew steadily after their official launch. Although the original target of 3 million units a year has been closely approached but not yet met, Honda's ZE models have become an important base of support for the company's power product operations.

The ZE engine's overall excellence is demonstrated by the fact that since its release manufacturers of general purpose engines around the world have adopted the OHV/inclined cylinder concept, making it the de facto standard. However, when it comes to OHV technology, every manufacturer has had an equal opportunity to apply it. Therefore, there are several reasons for Honda's dominance in that regard, one being the technological capabilities accrued through years of motorcycle and automobile development. The development staff, too, had worked tirelessly to achieve its goals. However above all, the engine's success was driven by "Hondaism," a unique set of philosophies shared by company employees, for whom customer satisfaction is the ultimate objective. They had decided to go with the OHV configuration at a time when no other manufacturer could, simply because they desired a way to please the consumer. They wanted to combine technology and real-world information in a way no one before them had.