The World's Smallest Welding Line / 1982

The Foundation of an Automotive Facility

Honda began producing the T360 mini truck at Saitama Factory (currently Saitama Factory's Wako Plant) in June 1963, with production of the Honda Sports S500 beginning at Hamamatsu the following August. With the production of these models, Honda had at last achieved its dream of becoming an automobile manufacturer.

The welding line for the L700 light van, which debuted in September 1965. The line operators performed their work using bulky welding guns and auxiliary cables.

Initially, the white bodies of these models - the welded and assembled body prior to painting - were comprised of medium- to small-sized pressed sections. Although such pressed parts were easy to make, they added to the steps required for welding and assembly.

Soichiro Honda's philosophy on manufacturing was "the fewer the steps involved in a process, the higher the quality and efficiency." In keeping with that philosophy, the company sought to manufacture quality vehicles while demonstrating the efficiency it needed to compete with well-established automakers. Therefore, Honda adopted a new "building block" system for white-body production. Designed to build car bodies with large, one-piece formed panels, the new system was the embodiment of Mr. Honda's original concept for the new N360.

The accompanying welding line began with a subassembly welding process in which various body parts such as the side panels, roof, and floor were assembled. Next, the main assembly welding process combined these parts into an integrated body, and an additional welding process was performed on the assembled unit.

Then, in 1967, Honda introduced a new body-welding system to the line at Sayama Factory (now, Saitama Factory's Sayama Plant) which was intended as a production facility for the N360. That system consisted of PW (press welder) welding machines and a GW (general welding) machine. These were responsible for the subassembly process and main assembly process, respectively. Both machines were designed for enhanced accuracy and quality in body welding, along with a reduced cycle time. However, the press welders of that time had poor welding efficiency and the operators had to correct many of the machine-welded points by hand.

The general welder was by comparison a highly efficient, integrated system capable of building the entire body frame in a single process and at a high level of quality. Still, it had the inflexibility of a dedicated welding machine, and as such, it required a setup of several hours for the N360 or any of the LN360 series models each time the settings were changed.

The additional welding process was one in which the line was covered with a number of portable welding guns hanging down from the ceiling via bulky auxiliary cables. Each operator, having to work with one of these heavy units, would continually grapple with the cables. It is no wonder, then, that they often referred to their workplace as "the portable jungle."

The N360's anticipated monthly production volume was 5,000 units per month when the line first went into operation. However, the car was such a hit upon its March 1967 release that Honda had to implement several dramatic changes to the line in order to meet the demand.

"Dedicated (welding) lines like the one created for the N360 required considerable investment each time the production volume for a target model was changed," recalled Nobuji Maezawa, who as technical adviser at Sayama Factory's Second Plant was in charge of the design of welding machines. "We used to argue that the new welding lines we were designing would have to accommodate the inevitable expansion of Honda's model line," he said.

Personnel from Sayama's Second Plant (formerly the Manufacturing Machinery Plant) and the H1300 Special Planning Office got together in 1969 in order to collaborate on modifications to the subassembly press welder. Their purpose was to better equip Suzuka Factory in producing the Honda 1300. The result of that effort was a new sliding general welder developed for the main assembly process. The system employed a modular structure for increased flexibility in the production of multiple models, permitting the separation of the main unit and fixture jig (which facilitated the welding). The new machine made it much easier to change settings from one model to the next, shortening the changeover time to 15 minutes.

The sliding general welder installed in Suzuka Factory in May 1969 for use in production of the H1300. Once the body was set, the machine clamped it with the welding jigs on both sides to perform general welding. (Photograph courtesy of Yuji Ikeda).

An improved sliding general welder (GW) was introduced to the line at Sayama in 1970. This unit was equipped with a changeover mechanism that could automatically change the dedicated welding jig attached to the main unit. Such an addition would enable the Sayama and Suzuka factories to handle the same models on each of their welding lines.

Honda's First Industrial Robot

The 1970s were a time in which Japan's various industrial sectors began introducing sophisticated facilities incorporating industrial robots and computer control technologies. In particular, several machine-tool manufacturers began selling welding robots, thus promoting the automation of spot welding. In response, the carmakers absorbed robotics technologies into their welding lines. Still, the industrial robots available to auto manufacturers in those days were fairly large and cumbersome.

Moreover, they offered a relatively limited range of functionality.

Honda, however, was already at work studying the latest robotics methods in Europe and the U.S. The Manufacturing Machinery division (currently Honda Engineering) was in charge of production facility development for Honda's factories, and based on its findings, Honda was in 1973 able to develop its first robot, the HRB600. It was not an effective application, however, and only one unit was installed on the hood-welding line at Suzuka. The HRB600 simply imitated the operations traditionally performed by hand, and as such merely extended the line. It could not provide the solution Honda needed in order to make its line more self-sufficient.

Subsequent forays into robotics eventually led to the development of robots having unique functions. These units would in fact play an essential role in the new welding system the company later developed for multiple-model car production.

Pursuit of Highest Efficiency Creates Multi-Function Robots

Honda established Honda Engineering (EG) in July 1974 through the consolidation of its production engineering and pre-production operations. Under EG's leadership, various measures were rapidly implemented for the purpose of achieving greater cost-effectiveness and quality, the keys to Honda's growing international competitiveness. Particularly, the enhancement of body-welding systems was given top priority, given that the company was working hard to restructure its product-mix by shifting emphasis from mini cars to compact cars.

EG, endeavoring to develop a more rational, compact welding system, worked to reduce the size of clamp guns incorporated in the subassembly welders and fixtures for the general welders. As a result, there was much greater integration throughout the welding process.

Honda developed a more rational, TT-type (tabletop) welding machine in 1975, intending that it would replace the PW unit. This was in preparation for an anticipated increase in production demand for the Civic and subsequent model developments, as well as for enhanced efficiency in subassembly welding. Subsequently, the TT welder was adapted to the subassembly processes at Suzuka and Saitama Factory's Sayama Plant. However, the effect of the new machine was not such that it could eliminate the portable jungle from the additional welding process, where operators continued their manual welding. Moreover, the development of new car models and increased production volumes required more dedicated jigs per model. Invariably, this led to a more exclusive investment for each model.

In December 1976, EG developed a simple, yet efficient function robot specifically for the welding of floors. A "function robot" is one designed to serve one specific function. The new robot was designed to eliminate the need for the operators to carry a heavy welding gun down the line in order to weld the floor of the car body. However, this robot had neither a long arm nor a shape resembling the human body. Instead, its main characteristic was the ability to move in linear fashion according to the floor contours, and this allowed it to spot-weld more sections in a shorter time than could the operator. The army of new robots, which were placed along the line for floor subassembly welding, earned the descriptive name "floor multi-robot welding station machines." As such, they were the first step in Honda's development of a robotic welding system.

The Challenge: Integrated, High-Density Welding

Various studies were underway at EG regarding the development of a new welding system. The project team was made up of personnel having expertise in different aspects of welding, including welding guns, jigs, and total systems. Ryo Niikawa, then an engineer in the Second Engineering Block, was appointed to the post of PL. He recalled having doubts about the new welding system at the start of its development.

"Mr. Ishikawa (Fujio Ishikawa, then the senior managing director at EG) asked us if we could achieve half-size production'; that is, halving every aspect of production from facility and space to processing and personnel. To be honest about it, I wasn't sure we could do such a thing."

The development team began its research regarding the new welding system with a detailed study of the subassembly, main and additional welding processes, employing as its basis a series of drawings and models. Their findings were then used to outline a rational concept for process configuration and facilities.

A conventional welding line based on the building-block system employs component parts that have been welded and assembled in the subassembly line for forwarding to the general welder. Thus, the development team reviewed the GW's program of operating times in order to study the flow of the overall welding process. In main assembly the side-panel setting jigs attached to the right and left sides of the GW would retreat once general welding was completed, sending the body downline to the next process. The machine would then perform and complete positioning of the new body fed from the previous process and prepare for the next welding operation. Next, the jigs used to set the right and left side panels would advance, and the general welding operation would begin. Therefore, with this in mind, the development team established its target. They decided to utilize the interval during which the right and left side panel setting jigs would wait while the new body was being fed.

Specifically, they thought that integrating the GW's side-panel setting jigs with the side-panel inner/outer welding jigs used on the subline and allowing subwelding to be completed during the free interval would allow the integration of steps within the overall cycle time. To realize such a facility concept, the team came up with an innovative idea. They would turn the general welder's side-panel setting jigs outward and directly set side panel inner/outer to the jigs, then perform the welding while the jigs were turning inward, thus finishing the job before the jigs returned to their original positions.

Two key issues had to be resolved, however. The first was to develop a mechanism and jigs that would allow subwelding to be completed while the jigs were turned inward, and then guide the panels into their correct positions on the GW for welding via the main assembly. This meant the team was able to devise a workable solution based on an existing technology.

The clamp-gun positions presented the second challenge, in which combining the existing work clamp and welding point specifications would result in interference among the clamp guns. However, most of the welding points were intentionally allocated to welding machines on the main and subassembly lines in order to remove some of the burden from operators during the additional welding process. Accordingly, changes in clamp-gun positions could affect the concept of the entire line. But seeing the issue from a different perspective, the development team decided to relegate the welding points to a high-efficiency, high-density robot station that was being developed for the additional welding process. In this, the idea was that the transfer of welding points would minimize the total number of welding points in the main and subassembly processes, integrating several steps in the process.

The Birth of Honda's Original Monkey/Crab Robot

The development of a new welding machine thus under way, the staff members who had been working on robotics began examining a robot station with which to control the additional welding process, based on the overall concept of the new welding system.

"Instead of making robots that would simply copy work that would usually be performed by humans," said Sakae Takaishi, then on the Board of Directors at EG, "we tried to identify the forms of process or operation suitable for robots. We believed the development of robots wouldn't benefit us unless we understood those particular characteristics.

"Men can't work while hanging from the ceiling upside down, like monkeys. It's also very painful to crawl under the cars like crabs and work for hours while lying on our backs. On the other hand, machines can operate just as efficiently even when they are suspended from the ceiling or placed face-up under the car. This was the underlying concept in the new phase of Honda's robotics development."

The new robots had to be small, lightweight and capable of high-speed operation. To achieve these goals, the team members began by reducing the size of the transformer in order to facilitate integration of the robot and gun. One particular problem was the auxiliary cables connecting the gun and transformer, which with their bulk and length resulted in considerable current loss, thereby limiting the robot's movement. And of course the cables necessitated a larger amount of installation space. Moreover, the auxiliary cables were easily damaged because of the impact the cables exerted upon themselves by bouncing up and down each time the power was supplied. Accordingly, the loss of durability was a concern. For these reasons the team members set as their prime objective the elimination of auxiliary cables. At the time they would work on reducing the size of the clamp guns incorporated in the fixtures of GWs, PWs and TT welders. The team confirmed that these cables could be eliminated by using the technologies and know-how they had so far obtained.

Therefore, in regard to the overall investment in and efficiency of the new welding system and robot station, the team confirmed that the target requirements could be met. Accordingly, they wrapped up their basic research on the overall system and shifted to the next phase.

The Innovative One-Pack SM System

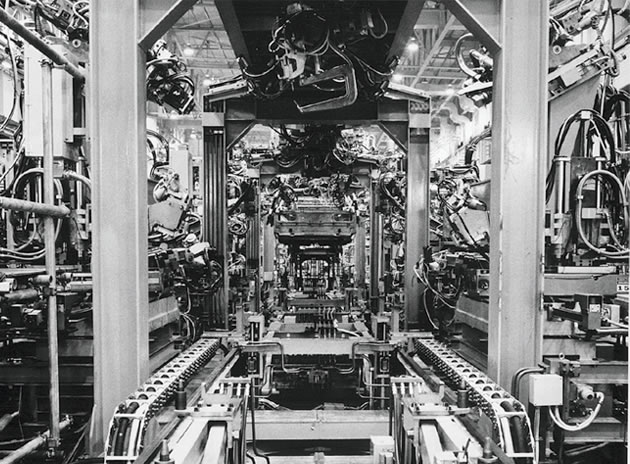

EG began designing/building the main GW in February 1979 with the intent that it would become part of the new welding system they were planning to introduce to the mass-production line. The mechanism of the system was as follows: A carriage jig was used to position the floor assembly welded on the subline and feed it into the main GW. Then, the inner and outer side panels were introduced from the sides of the GW and placed in the welding jigs. The parts were then welded as the jigs turned inward, upon which they would be transferred to the carriage jig. Subsequently, the roof, upper dashboard and rear tray were assembled from above the GW and simultaneously spot-welded at approximately 150 points. This mechanism facilitated the completion of the white body in just one process. Jig changeover was completely automated (around five minutes), making it ideal for the production of multiple models. The system was known as the SMGW, with SM standing for the initials of subassembly and main assembly, since it integrated the subassembly and main assembly of side panels.

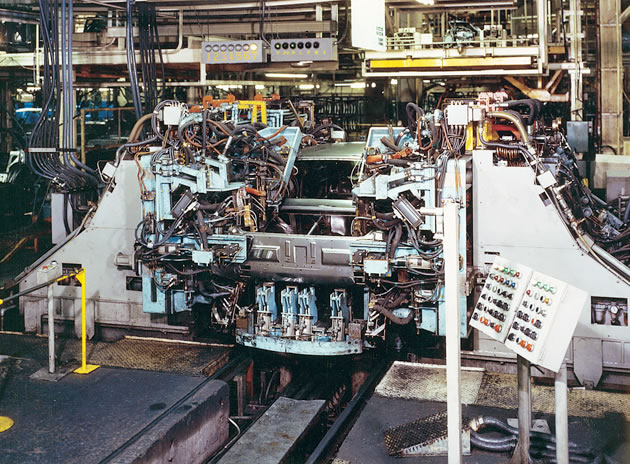

The robot station, which makes up a part of the one-pack SM system. The robots shown in the upper portion of the photograph are called monkey robots, while those shown on the bottom right and left are crab robots. (Photograph courtesy of Genzou Fuse)

The development of Honda's new robot station began in April of that year. Based on the station concept of integrating robots programmed for different operations, the team worked to design small, lightweight robots having the optimal dimensions and structures for their respective sections, including door and window openings along with general body surfaces. Four types of robots were conceived for different welding operations, and flexible installation positions were adopted according to the sections to be welded. For example, the floor-welding robots were placed at sides, while those used to weld window areas were suspended from above. This contributed to a reduced requirement for installation space. These robots were called "function" robots.

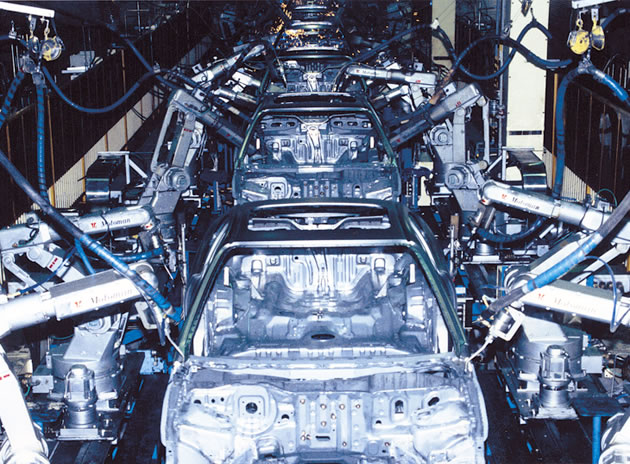

The function robots comprising the additional welding process.

The development team systematized these original Honda function robots and installed a total of fourteen units. Eight units were positioned at the first station in the additional welding process, while six were placed in the second station.

The robots were called "monkey" and "crab" robots, according to their points of installation. The monkey robots, installed on the ceilings and walls around the robot station, were mainly used to weld areas around door openings and front/rear windshield mounts. The crab robots, placed on the floor, were used to weld body floors. Since the monkey robots and crab robots were placed three-dimensionally above and below, and to the right and left of the line, they gave rise to the allusion "monkey and crab war," which became a popular phrase at EG. Unlike the famous Japanese "Monkey and Crab War" folktale, which is basically a story of vengeance, the "monkey and crab war" here referred to a joint attack by a united army of monkey robots and crab robots, which performed additional welding of various body sections at once from all directions: above, below, right, left, front and rear. These robots eliminated the portable jungle from the welding line, further enhancing the integrity of body welding and assembly.

The use of a teaching function also allowed each of the function robots to learn the different operations employed for different models. Switching between these settings was automatic, creating an effective system that was conducive to multiple-model production.

Installed along the newly developed welding system were the subassembly machines, which were dramatically downsized through the use of process integration, and the robot stations, both of which were placed close to one another. The completed line was much smaller than conventional welding lines of the period. This system is generally called the one-pack SM system.

Exporting the One-Pack SM Systems

Honda made an important announcement in January 1980, saying it would build a new automobile plant in the Midwestern state of Ohio, U.S.A. In May of that year, prior to its planned introduction in the new plant, which was to operate under Honda of America Manufacturing (HAM), the one-pack SM system was put into operation at Suzuka Factory. Initially, though, the system caused disturbances in production due to malfunctioning jigs and guns, in addition to poor yields arising from deformed bodies, etc. However, the engineers from EG worked with factory staff to devise creative countermeasures, leading to improved jigs and guns and greater accuracy throughout the welding process.

EG began assembling the system for HAM in August 1980. Concurrently, the local staff sent by HAM stayed at EG to receive an orientation in system operation and maintenance procedures via hands-on training. Through their involvement in mass-production trials, the American staff were able to produce a dramatic increase in skills. Thus, the HAM production line turned out its first Accord in November 1982. Thanks to the one-pack SM system, the new plant was able to produce vehicles with the same high accuracy of body welding as were the Japanese factories.

A year later, when the Accord underwent a minor model change, and when the three-door model was introduced, HAM was able to start the new line with a shorter lead time, using dedicated jigs for the new model brought in from Japan, where they had been verified for mass production.

And here one of the key benefits of the one-pack SM system was demonstrated. Compared to the former 77 steps required by a conventional welding system, the new welding line had just 29 steps. Moreover, the percentage of automated tasks among all spot-welding work had increased from approximately 74 percent to 89 percent.

Since the robots used the teaching function to memorize the transitions from one model to the next, the amount of investment required for dedicated fixtures in model changeovers dropped, as well. Finally, in 1984, in order to eliminate the remaining 10 percent of manual spot-welding tasks, EG developed a final spot robot (FSR) that could travel along the ceiling. As the number of FSR robots increased, the automation ratio approached 100 percent. Accordingly, an effort was made to further simplify the changeover process during production.

The one-pack SM system brought a new kind of innovation to Honda's welding lines, achieving a significant degree of rationalization along with greater intermodel flexibility. In fact, the SM method -accurately described as a highly integrated, high-density body welding system- went on to win the Okouchi Memorial Award for Production in 1986.

The one-pack SM system is still in use today at Honda's key production bases in Japan and overseas, being an important element in car production. Designed for enhanced efficiency in multiple-model, small-volume production through rapid response to changing conditions of production, the system is recognized as the world's smallest welding line. It has without doubt been a key element in Honda's evolution as a global competitor of unmatched technical capability.

The foundation of Honda production technology is the unending dedication to integrity in manufacturing. This ideal has been kept alive by generations of Honda engineers, going back to the establishment of the company half a century ago. It is an ideal that has provided the fortitude to face and endure tough logistical issues, no matter how difficult they might have seemed. In the process, they employed their youthful energy, passion and intellect, striving through daily challenges for the betterment of themselves,the company and its products. It was just that spirit of challenge that enabled Honda to create the world's smallest welding line.