Introducing the CVCC / 1972

The 1970 U.S. Clean Air Act

Japan was only just entering the age of motorization in the mid-1960s, when it began experiencing the problem of smog. Then, in July 1966, the country’s Ministry of Transport introduced a standard regarding toxic gases emitted by automobiles, making it mandatory to reduce CO emissions to a maximum of 3 percent for automobiles (gasoline cars, except for mini cars) produced after September of that year. In August 1967, the Basic Law for Environmental Pollution Control was implemented, and in 1968, the Air Pollution Control Act took effect.

Soichiro Honda at the CVCC introduction held at the Akasaka Prince Hotel in Tokyo on October 12, 1972.

Air pollution was not simply a problem that could be controlled by laws alone, however. On May 22, 1970, a physician’s co-op in the Tokyo district of Bunkyo-ku, brought the problem to the nation’s attention. Based on the results of an exhaustive examination of residents there, the doctors announced that "lead levels in the blood of residents living near the Ushigome-Yanagi-cho intersection in Tokyo’s Shinjuku-ku, is unusually high," raising speculation that the lead with which gasoline was formulated might be the culprit. Then in June, the Ministry of International Trade and Industry (MITI) issued a notice regarding the prevention of lead pollution from automobiles, presenting guidelines with regard to the amount of lead that could be added to gasoline. Additional proof of the dangers was soon to come. On July 18 of that year, the occurrence of photochemical smog victims on the grounds of Rissho High School in Suginami-ku, Tokyo, became a social issue. The incident intensified the public’s demand that emissions be reduced and regulated. It was a sequence of events that led to the July 1971 establishment of the Environment Agency, a government bureau set up to safeguard the health of Japan’s population and resources.

The U.S. government was active in the crusade as far back as 1963, when it established the Clean Air Act, to which the Automobile Emission Control Act was added 1965. In 1966, the California State Government established its Air Resources Board, which began restricting emissions even further. As a means of promoting public awareness and disseminating information about its activities, the federal government published its official Air Pollution Control Regulations in the March 20, 1966, issue of the Federal Register.

The U.S. was determined to promote environmental policies against pollution. In 1970, the job of environmental administration was transferred to the newly established Environmental Protection Agency (later upgraded to a Department, now the EPA) from the Department of Health, Education and Welfare (HEW). Concurrently, Senator Edwin Muskie submitted his clean-air bill - known as the Muskie Bill - to Congress. It was a major revision of the existing Clean Air Act, and its standards were more stringent than ever before. It stipulated that automobiles made in 1975 and thereafter should emit one-tenth the level of CO (carbon monoxide) and HC (hydrocarbons) compared to current models, while models 1976 and later should also emit one-tenth the level of NOx (nitrogen oxides). It was going to be challenge. In fact, the world’s automakers maintained that it would be almost impossible to meet such strict standards. Undaunted by the industry’s complaints, Congress passed the 1970 Clean Air Act on December 31, 1970.

Launch of the AP Lab

Honda R&D Center put together a ten-member Air Pollution Research Group in the summer of 1965, in accordance with its expectations regarding the future of automobile exports. Established by Shizuo Yagi, leader of the company’s Engine-performance Research Block, the new group consisted of members of Yagi’s own section. They began by collecting data on legal trends in America’s air pollution regulations.

In September of that year, Kunpei Ito, of the Technical Research Lab, conducted a survey on air pollution caused by automobile emissions in Japan and the U.S. His work included studies on air-pollution regulations and how other automakers were dealing with the situation. He even educated research and design groups by holding a meeting to report his findings. It was at such a meeting that Tasku Date (then Honda R&D director), Yagi and Kazuo Nakagawa (then the Engineering Design Block’s chief engineer) agreed on the need to promote full-scale research into emissions control. From that point on, they used every available opportunity to persuade the company to open a laboratory for air pollution research.

Honda, though, had only recently emerged on the automotive scene, so the business at hand was to develop its next car. Moreover, in January 1964, the company announced that it would enter F-1 Racing. The company, it was explained, could not afford to waste time and human resources on air pollution research that would have no immediate result.

The Japan Automobile Manufacturers’ Association (JAMA) organized a committee in June 1966, for the purpose of touring the U.S. on a study of automobile emissions. Honda’s Yagi was one of the members. The tour lasted one month, with which the members visiting 23 research labs at GM, Ford, and Chrysler, as well as government agencies and universities. They studied the most current research on emissions and safety.

Since Date, Yagi, and Nakagawa had been advocating research into air pollution, they went to Hideo Sugiura, the general manager of the Research Center, and told him it was essential that they make the trip.

"All right, then," said Sugiura. "Let’s do it."

The Air Pollution Control Research Lab (AP Lab) was thus launched with a hastily assembled team of about thirty members. Even with the launch of the lab, the research engineers had to study the new field from scratch. Having pursued engine design from the perspective of high revolutions and output, the control of emissions seemed like an entirely different world.

"We had no answer as to what caused air pollution, back then," Date recalled. "All we had was a device that measured carbon monoxide. We even had to ask what NOx and HC were, since in Japan there were no devices available to measure them. At first, we used something called a gas chromatograph to see the color reaction when exhaust gas drawn into a syringe was treated with chemical reagent. With this method, however, the engine condition would change while we were taking measurements. We simply were not able to apply our findings."

The team at the AP Lab could only begin by researching measurement methods and devices. However, Soichiro Honda had high hopes for the AP Lab. "Honda Motor," he said, "is the newest member of the auto industry. And this is a great opportunity to be at the starting line with our competitors."

Achieving Lean Combustion through Trial and Error

The first thing the AP Lab did was inspect its competitors’ research on emission control through experiments, as well as to conduct surveys and research. Then it would provide information to the Honda R&D Center.

Surveys were conducted on a variety of possible emissions control methods, from enhancements in gasoline and diesel engine technologies to alternatives such as gas turbines, rotary engines, and Stirling engines. They even studied post-processing devices such as oxidation catalyst and thermal reactors, and alternative fuels such as alcohol and hydrogen.

As part of its promotional efforts the AP Lab put together its own newsletter called AP News, distributing it within Honda R&D Center and associated divisions. The magazine featured information about future changes in work procedures regarding car design, manufacturing, maintenance, and other steps to deal with emissions regulations in Japan and the U.S.

According to Junji Otani, then designer of the Engine-Performance Research Block, Mr. Honda instructed the research engineers to use existing engines. "It would be a tremendous task to get rid of existing gasoline engines in an attempt to control emissions," he said. "We would have to throw away our entire manufacturing facility. Needless to say, such a measure was not possible. The regulations would simply have to be met with existing engines. That’s why we had to rebuild our current reciprocating engines."

The AP Lab decided to base its emission control research on intake and combustion controls. Since the toxic substances were still released following treatments using other methods, their approach was to treat toxic substances with post-processing devices.

Catalytic converters were at the time being made for stationary facilities, such as factories, to treat smoke emissions. Such devices typically consisted of a tube containing catalytic agents in pellet form. The effectiveness of such a system was thus at a level in which it could comfortably satisfy the 1970 Clean Air Act. However, when attached to an automobile, the device wore thin from vibration or would even burn to a crisp, depending on the quality of combustion. Durability was much in need of improvement.

The team also found that when materials were not completely burned in the combustion chamber, the thermal reactor would reignite them at the emission stage. However, in order to ensure thorough recombustion, a higher air-fuel mixture would be needed. But that decreased the engine’s fuel efficiency.

Therefore, there had to be some other method they could try. Soichiro Honda had numerous suggestions for the lab, among which were the promotion of fuel vaporization during intake using a new mechanism; and the maintenance of proper intake through a system of fuel injection.

At the time, Tsuyoshi Asanuma, a professor at the University of Tokyo, was paying regular visits to Honda R&D Center once or twice each month as an adviser. The research members would share their opinions with him, and became convinced that the only method to reduce the emission of toxic CO, HC, and NOx altogether was to adopt the lean-combustion method, which would burn the fuel more completely. However, this challenge seemed impossible with the degree of technology that was available to them. However, they remembered a frequent remark by Mr. Honda: "What can you learn until you try?" And with that, the team began its basic research into lean combustion.

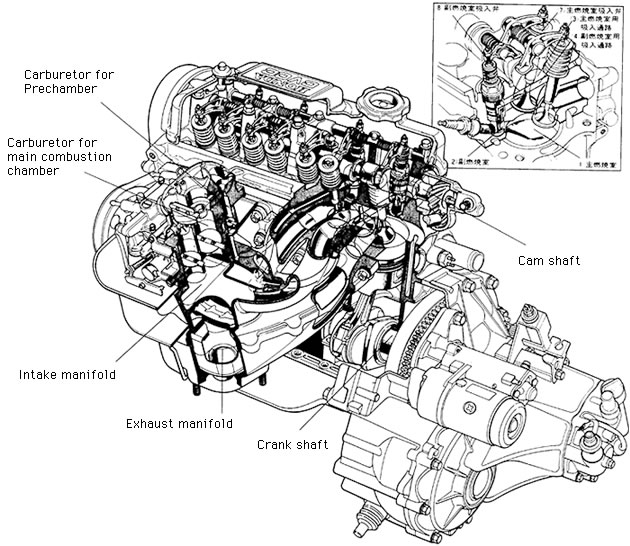

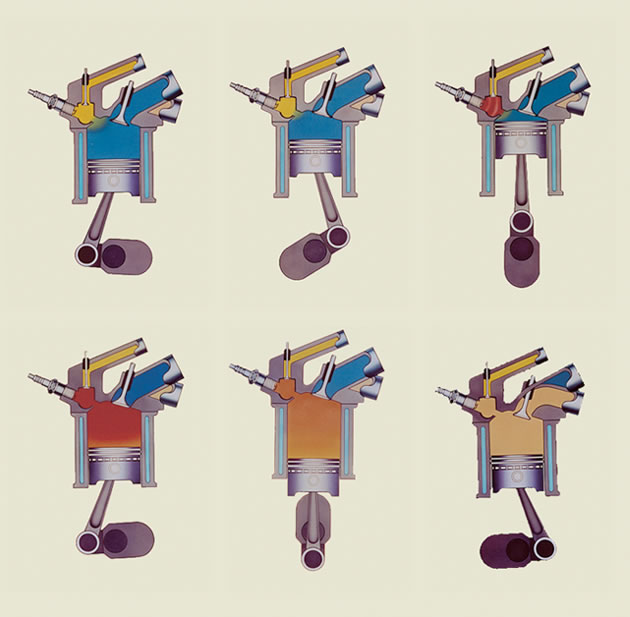

A reciprocating engine operates in the following manner: First, the air-fuel mixture is pressurized in the combustion chamber and ignited. The resulting explosion forces the piston downward, away from the spark. This motion is repeated over and over, being transformed into a rotary motion through the use of a crank. It’s a relatively simple process. The stoichiometric mixture ratio for gasoline engines is about 14.7. However, the common blend is higher in fuel than the stoichiometric ratio, because a leaner mixture tends to cause unstable combustion. Accordingly, a mixture that is higher in fuel results in lower gas mileage when compared to an engine that uses the stoichiometric mixture. Since combustion is incomplete, the mixture inevitably generates toxic byproducts. To maintain the proper combination of performance, efficiency and low emissions, it would be necessary to realize a technology that would stabilize combustion at the stoichiometic mixture ratio. Possibly, it should be even leaner than that.

Tests were conducted using every method of measurement imaginable, from heating the mixture and reinforcing the gas movement in the cylinder to increasing the ignition energy and achieving multiple ignitions with several sparkplugs at once. But nothing managed to produce a satisfying result.

Developing an Engine with a Prechamber

The process of trial and error continued, leading Date to conclude that it would be difficult to catch up with the competition in Japan and America. After all, if Honda were simply to conduct the same type of research as others are doing, there would be no competitive edge. Date decided that Honda should take another route. He conferred with Yagi and Nakagawa about the possibility of creating lean combustion via a prechamber. He knew this was a feature not used in conventional engine designs.

True, some diesel units had prechambers, and research was being conducted in the Soviet Union to achieve a similar process using a gasoline engine in order to use low grade fuel or to improve fuel economy. Since no research was being conducted for the purpose of controlling air pollution, it was decided that the pursuit would be worthwhile. Accordingly, the research on prechambers began, with the N600 engine as the basis for modification. Otani and Akira Okubo, who were in charge of design, did not have a minute to spare. They could count on regular appearances from Mr. Honda, popping in with instructions as he studied the plan.

"Just when we were about to give our plan its finishing touches," recalled Otani, "Mr. Honda would give us new instructions. It always meant we’d have to redo it all from scratch." Soichiro Honda had no patience for the long wait required to see completion of the trial engine manufacture. "We have engines with prechambers among our general-purpose engines, don’t we?" he said. "Why can’t you conduct research using those until the trial engine is completed?" With that, a series of tests began using the GD90 general-purpose disel engine.

The GD90 was a 2-cylinder, V-type 479 cc diesel unit with a prechamber; the ideal engine for their experiments. First, the researchers installed a sparkplug and gasoline-injection nozzle in the prechamber, remodeling the engine to allow the pressure ratio to be adjusted between 8:1 and 16:1. Tests using the converted GD90 were then conducted from December 1969 to February 1970, and the results seemed to indicate the possibility of a gasoline engine having lean combustion.

A trial-manufactured version of the single-cylinder, 300 cc N600 engine was completed in January 1970, allowing for the start of testing. It was the team’s goal here to determine the optimal conditions for a prechamber, so that lean combustion could be achieved. During their research Mr. Honda suggested, "Why not use the mechanical fuel-injection system we developed the other day?" (That system was introduced in October 1970.) It seemed to make sense, and with that the appropriate research was conducted using two fuel-supply methods: fuel injection and carburetion.

The basic CVCC operating mechanism, with the accompanying process

Subsequent to that, the team took up research on water-cooled engines, all the while keeping in mind the goal of emissions control.

However, Honda lacked water-cooled automotive engines that could be used for testing. Therefore, since they needed to proceed right away, tests were conducted using Nissan 1600 cc engines and other units. These tests unexpectedly produced a welcome byproduct: By using competitors" engines, their data would offer a more general application.

The Official Name: CVCC

When Soichiro Honda heard that research had determined there was a prospect of reducing toxic substances using the N600 engine, he declared that he would make a public announcement about the low emission engine.

Date, Yagi, and Nakagawa immediately convened in the reception room at Honda R&D Center, in order that they might come up with a name for Honda’s new engine. The official name they decided on just before the announcement was "CVCC," an acronym for "Compound Vortex Controlled Combustion."

"Even though we had determined the possibility, we were still in the middle of research," Date recalled. "In fact, we were still processing our patent application. This meant that the name of the engine had to be contrived carefully, in order that the public announcement not reveal even a part of its structure. And we were as yet undecided about how to supply fuel. We got our heads together to come up with a name that was unique; something that had a bit of punch to it."

C ("Compound") represented the engine mechanism with two combustion chambers: main and auxiliary. V ("Vortex") represented the vortex, or swirl, generated in the main chamber. Caused by a jet of flame from the prechamber injected via a nozzle, the vortex had the effect of increasing the speed of engine combustion. CC ("Controlled Combustion") represented the engine’s ability to properly control the speed of combustion.

Answering the question as to why the engine was publicly announced while it was still being researched, Yagi simply said, "Mr. Honda told us, ‘If I asked you guys when it would be completed, you’d never tell me that you had it completed to a tee. The company would go bankrupt before you’d say that.’ So, he took a chance, announcing it publicly once it was clear that the prospect for such an engine existed.

"As we say at Honda, it was Mr. Honda’s habit to ‘leave you upstairs and take down the ladder.’ By making a public announcement on the CVCC, I believe he aimed to build up our morale. In the process, he could promote our work in research and development."

Soichiro Honda held a news conference on February 12, 1971, at the Federation of Economic Organizations Hall in Tokyo’s Ote-machi. There he announced, "We now have the prospect of developing a reciprocating engine (CVCC) that meets emission regulation standards for 1975. We will launch the commercial production of this engine in 1973." Indeed, the announcement inferred that there was a chance of satisfying the requirements of the U.S. Clean Air Act. Moreover, in the February 26 special issue of the Honda Company Newsletter Mr. Honda informed his employees that the prospects of doing so were quite good.

Many problems had yet to be resolved, though. First of all, the company had to prove that the technical concept of an engine with a prechamber was effective for use in actual automobiles. The new engine was to be installed in the Civic, a small passenger car then in the process of development. Though the engine displacement had been determined according to that product, it was concluded that it would be necessary to develop a 2000 cc CVCC engine, based on standing data and simulation results. This was because in order to clear the emission level stipulated by the Clean Air Act, the engine had to be operated with the air/fuel mixture of around twenty across entire engine load.

The engine was thus given the development number 993. A blueprint was drawn, and just two months later the first prototype engine was completed. An additional 100 units were manufactured with the help of workers at the Saitama Factory (now Wako Plant). The engines were installed in Nissan Sunny bodies following bench tests of their basic performance. Then the chassis dynamometer tests began.

As predicted, lean combustion through the prechamber method reduced CO, NOx, and HC, although the figure for HC was not quite up to the 1975 standards of the Clean Air Act. However, subsequent research on the manifold emissions system, combined with the right combination of main chamber, prechamber and fuel-supply method, produced the desired oxidation reaction in the exhaust pipe through the heat present in the exhaust gas. This resulted in the reduction of HC, consequently revealing the possibility that Honda’s new CVCC engine would satisfy the U.S. standards without the need for a catalytic converter.

The U.S. Environmental Protection Agency required that automobiles continue to meet the standards after 50,000 miles of driving. Thus, research was continued on a fuel-supply device that could supply the ideal air-fuel mixture under any conditions. Moreover, they began to look for a durable structure that was capable of generating more stable oxidation at the exhaust pipe.

The CVCC Engine System: An Immediate Success

October 11, 1972, was a landmark day in the history of Honda. On that day at Tokyo’s Akasaka Prince Hotel, the CVCC engine was introduced in its entirety to journalists from throughout Japan and the world. The hall was decked out in blue panels representing a brilliant blue sky, bespeaking the achievement of this new, low-emission product.

The event was attended by all company directors, including President Soichiro Honda, and by the research engineers responsible for developing the new power plant. They introduced the engine, profiled its history of development, and described its features and combustion principle.

Several achievements were introduced, including the following:

1. The engine could be made using existing reciprocating engines, which meant that existing production facilities could be used. In addition, because the only change required was the replacement of a portion of the cylinder head, the CVCC system could be applied to other types of units, resulting in the proliferation of low emission engines.

2. Because clean, complete combustion took place internally in the engine, additional devices such as catalytic converters were not necessary. Secondary pollution was no longer then a concern.

It was clear with this auspicious announcement that Honda had championed a new technology for the world. Moreover, it was just what Mr. Honda had in mind from the very beginning. And by that time some 230 patent applications were already pending with regard to comprehensive inventions covering the CVCC engine principle and associated technologies.

"Some of our competitors conducted good research, as well," said Yagi, obviously stressing Mr. Honda’s philosophy on the origination of technology. "They didn’t have the means to make it all happen, though. We at Honda did everything on our own, from the creation of a concept through to research and the establishment of a workable method."

Not only the press and industry observers were impressed. Once the public heard about the CVCC engine, the news of Honda’s achievement created a sensation in Japan and overseas. Subsequently, the EPA asked Honda to submit some cars equipped with the CVCC engine for testing. Honda sent three automobiles to the EPA’s laboratory in Ann Arbor, Michigan. Two had 15,000 miles on them, while one had completed a 50,000 mile durability test, which was conducted in the presence of Honda representatives December 7 - 14, 1972. Thus, the vehicle became the first to pass the stringent 1975 emissions requirements of the 1970 Clean Air Act.

"Test data was taken with the CVCC engine installed in a Nissan Sunny," said Ken Mizoguchi, the Honda representative on-site in Ann Arbor. "At that time, Honda still didn’t have a car that was big enough for the CVCC engine. We even used sandbags to try to increase the weight."

Indeed, the Civic had only been introduced a short time before, on July 21, leaving Honda with no alternative but to take the qualification test with the body of a competing vehicle.

Soichiro Honda had always made it clear that his policy was to make emission control technologies public. As Honda’s CVCC technology became available to other automakers, Toyota Motor inquired about it. Subsequently, an engineer from that company visited Honda R&D Center, where he test drove the car and was given details of the technology. Then, following a thorough evaluation of CVCC technology, Toyota signed a licensing agreement with Honda.

"It was a very positive sign when Toyota became the first to sign an agreement," said Koichiro Yoshizawa, who was in charge of negotiating the licensing agreements with outside companies. "In fact, it had a positive effect on both the CVCC and Honda. Once the news hit the papers that we had signed an agreement with Toyota, other makers in Japan and the U.S. immediately forwarded their proposals."

Licensing agreements were eventually signed with Ford, Chrysler, and Isuzu, and during that period Honda R&D was in constant receipt of visitors from auto companies around the world.

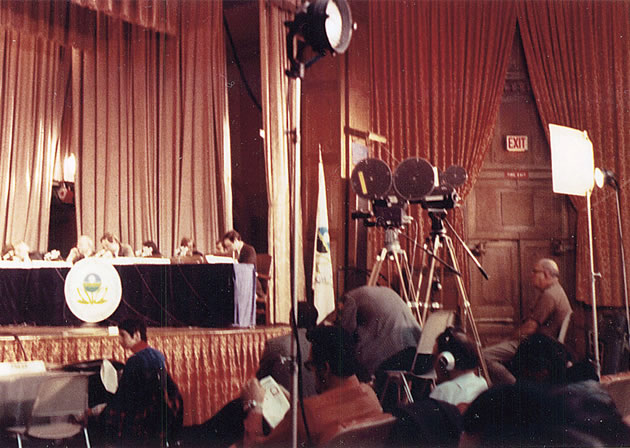

The EPA held a public hearing on March 19, 1973, in Washington, D.C., to hear the testimony of automakers on whether to implement the 1970 Clean Air Act as scheduled. At the hearing, the only automakers who testified that they could meet the 1975 regulations were Honda and Toyo Industries (now Mazda).

An EPA hearing was held at the Department of Agriculture building in Washington, D.C., on March 19, 1973. (Photo courtesy of Mr. Tasku Date)

"At the hearing," recalled Date, "we were asked, ‘Can Honda really produce cars that meet the 1975 requirements? And if so, can Honda supply CVCC engines to automakers such as GM?’ But honestly, we had our hands full just taking care of Honda’s business. We didn’t have the capacity to supply products to a company the size of GM. It was a very frustrating experience."

The demands were simply too much for the industry as a whole. So, as a result of the hearing, it was decided that implementation of the Clean Air Act would be postponed.

Civic/CVCC Fuel Economy Draws Praise in the U.S.

The Honda Civic went on sale in Japan on July 12, 1973. It was a car developed with the company’s back to the wall, at a time when the company considered withdrawing from the car business if the plan failed. But the Civic was well received in the marketplace, winning the 1973 Car of the Year Award sponsored by Motor Fan magazine. On December 13 of the following year, the four-door Civic/CVCC 1500 went on sale, giving the model name a solid basis for success in the Japanese market.

The first Civic/CVCC vehicle (December 1973)

Shipments of Civic/CVCC automobiles to the U.S. market began with the 1975 model year. Prior to exportation, however, the car had to be certified as satisfying the Clean Air Act. Even though the CVCC engine itself had passed the 1975 qualification test in 1972, it had not yet been tested as a complete vehicle. Emission tests in Japan a year earlier, using a 1974 Civic with normal engine specifications, had encountered no problems. However, at the EPA, the vehicle failed to acquire certification (although it passed after being retested.) Honda R&D Center was not about to be discouraged, though, and in the spring of ’74 it organized an EPA certification project in preparation for the Clean Air Act’s first year of implementation. The first task was to determine why the 1974 model had encountered problems during the test.

Honda R&D and Suzuka Factory worked together with the EPA’s Ann Arbor certification lab to find out why the test results in the U.S. had differed so much from those of Japan. Thorough comparisons were made, and the research data was collated for comparison.

Results showed three major differences between tests conducted in the two countries: Air pressure, chassis dynamometer and driving habits. Tests were affected by air pressure because the two test areas differed by 350 meters in elevation. Although the identical make and model of chassis dynamometer was used for both tests, it turned out that the span between the front and back rollers on Honda’s unit had been converted for easier testing on small cars. As for driving habits, it was determined that American and Japanese drivers differed greatly in their treatment of the gas pedal.

Based on these findings, Honda decided it would repeat the EPA’s test conditions in order to determine whether its own vehicle could pass the test. After that, they checked the influence of the new test conditions on automobiles that were to be mass produced.

The 1975 model of the Civic/CVCC was brought before the EPA in November 1974.

"With the test completed and the computer spitting out numbers," remembered Takeo Fukui, who was in charge of EPA certification, "I felt like I was waiting for the results of my college entrance exam."

"Congratulations!" said a cheering EPA inspector, offering his handshake when the test was completed.

Mizoguchi and Fukui were certainly overjoyed just for having achieved certification, but the EPA inspector told them their product also got the top rating for fuel economy.

"We were so preoccupied with emissions that we hadn’t given any thought to fuel economy," Fukui said. "But to the EPA, passing the emissions test was no big issue. It was fuel economy that mattered. After all, they had the future in mind."

The Civic/CVCC’s fuel economy figures continued to climb with each passing year, and as a result it was number one in that category for four straight years, through the 1978 model. It was soon common knowledge among American consumers that the Civic was a miserly user of gasoline. The car also drew praise as a low emission car that ran on either leaded or unleaded gasoline.

The Clean Air Act finally went into effect in 1975. Cars made by Honda’s competitors were equipped with catalytic converters, which meant they could use only unleaded fuel. Lead, of course, was known to have a damaging effect on catalytic converters. Once Fukui had completed the EPA’s certification process, he rented a car to test its fuel economy, driving from California into the neighboring state of Nevada. It was the latest model from Ford. On his way through the desert he stopped at a service station, where the attendant refused to fill up the car.

"The station didn’t sell unleaded gas," Fukui recalled. "I begged the manager for some gas, saying, ‘Please, I’ll run out of gas out here.’ But all he said was, ‘Sorry, I don’t want to be fined.’ Luckily, I was saved because the next station had unleaded gas."

Fukui was not to be alone in such an experience, as drivers across the country began to encounter similar situations. Besides the possibility of a fine, there were other measures intended to keep leaded fuel from entering the tanks of unleaded-only vehicles. Such cars had smaller fuel filler tubes, forcing gas stations to install narrower nozzles on their pumps that dispensed unleaded gas. Since the fuel industry could not meet the demand right away, relatively few stations were capable of serving unleaded cars.

The CVCC: Expressing the Honda Philosophy

Honda had pursued high-revving, high-output engines ever since it declared its participation in the Isle of Man TT motorcycle Race. Based on that kind of technology, the company began establishing a low emission engine technology with the belief that "dealing with the Clean Air Act wasn’t a company issue but a duty to which the industry at large was obliged; a pledge to keep as a responsible member of society." It was logical, then, to pursue the concept of a low emission powerplant independently, without concern that any other company might say it is or isn’t possible.

The CVCC system has today been superceded by innovations such as the three-way catalytic device and electronic fuel injection. But through the enhancement of a reciprocating engine using technologies available in the 1970s, Honda was able to meet stringent regulatory requirements. Thus, the company had achieved something other automakers had considered out of the question. By fulfilling its duty as a manufacturer, Honda spurred the entire industry into action on behalf of emissions control technology.

The CVCC engine had therefore come about through the cooperative effort of Honda’s divisions and departments. And ultimately the CVCC technology secured Honda’s position among carmakers around the globe. Especially in the U.S., the Civic spread Honda’s name and association with high-quality products, even enhancing its fame as a motorcycle maker. It was then that the foundation of today’s powerful American sales network was formed.

The CVCC engine was the first standard bearer of the lean-combustion concept; a goal that is still being pursued today. The legacy of such technology lives on in the LEV (low emission vehicle) engine and other innovations from Honda.