Launching the Honda 1300 / 1968

Let's develop a World-Class Car!

"This won't work! Change the design right away!"

Soichiro Honda, then the president of Honda, was a veritable fountain of ideas, issuing his instructions for one design change after another.

Hideo Takeda, who was in charge of frame design for what was to be Honda's first full-featured small passenger vehicle, attempted his reply. "I hear what you say, Mr. Honda. But they are about to start mass production at Suzuka, so to make additional design changes would only bring chaos to the line."

Soichiro Honda, welcomed by cheering employees, celebrates the first H1300 car off the production line at Suzuka.

Soichiro's face turned beet-red. "Damnit!" he shouted. "Chaos on the line is nothing compared to what our customers would have to suffer. Can't you understand that? Now, go to Suzuka and take care of it, right now!" He was resolute that the design changes be made.

Takeda was hesitant about going to the Suzuka Factory, knowing what he would be facing. He could almost hear the staff at the Engineering Department complaining: "What exactly are you trying to design at the R&D Center? If you keep changing the design like this, we won't be able to run the production line anymore!" Due to a previous series of requests for changes in design, there had already been numerous clashes along the way. Still, the time was approaching to issue a press release, as was scheduled.

The New H1300 - Debut of a World-Class Super Sedan

The slogan was enticing, reflecting the extraordinary effort that had gone into development of the company's newest product. With that, the Honda 1300 was unveiled on October 21, 1968, at Tokyo's Akasaka Prince Hotel.

The H1300 77 series released in May 1969

"We have developed the Honda 1300 as an international car that can be successfully marketed in every country around the world," announced Soichiro confidently. "The basic management philosophy of our company is 'originality,' and accordingly our goal has always been to spur demand by introducing original products that only Honda can create."

"By recognizing our social responsibility as an automobile manufacturer," he continued, "we have made a commitment to ensuring 'active safety design,' which is reflected in the car's ample power (96 horsepower with a maximum speed of 175 km/h), an FF control system that works on demand, as well as powerful brakes and supreme comfort. This new machine represents our first full-featured export model, and we are confident it will lead us to an era of free trade. We welcome your unreserved criticism. Market feedback is what will propel the Honda 1300 as a genuine car for the new era.

Unending Obsession for the Air-Cooled Engine

Honda's decision to build small cars, like its involvement in F-1 Racing, was simply an extension of the company's motivation to go forward. This time, as well, an ambitious goal had been set, as if to manifest Honda's challenging spirit.

"Now that we have made such a decision," Soichiro Honda said, "we must build a car that will take the wind out of the sails of Toyota and Nissan, who are already selling and exporting their small passenger cars."

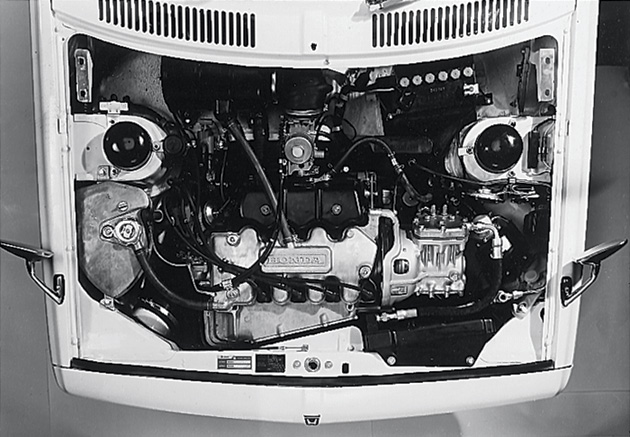

The H1300 77 series' engine room

Mr. Honda, who had taken the lead role in the project, spoke before his staff of young engineers at the R&D Center in order to raise their morale. The task was to develop an FF luxury sedan powered by an original air-cooled engine with high output and optimal efficiency.

But no one at Honda had any experience in the design of small passenger cars. They were indeed novices in the venture, having to study everything from scratch.

The car's specific content was determined at a planning review meeting held in September 1967. In order to give the product a competitive edge in the hotly contested small passenger car market, the focus was given to better performance and fuel economy - a combination that would be achieved through the use of a smaller yet more efficient engine than was common for vehicles in its size category.

Based on this objective, the development engineers set out upon that long, arduous road to the building of a car.

Mr. Honda had at that time already given orders to develop air-cooled engines for F-1 machines. Yet, even though he was convinced that air-cooled engines would dominate the world market in the future, Honda needed to prove his theory with F-1 machines before applying it to commercial vehicles.

Thus, the automotive development teams were about to grapple with three different design challenges at the R&D Center: air-cooled and water-cooled engines for F-1 cars, and an air-cooled engine for the H1300 passenger model.

"Since water-cooled engines eventually use air to cool the water, we can implement air cooling from the very beginning," professed Mr. Honda in his approach to the design of an air-cooled engine. "That will eliminate the problem of water leaks, and it will facilitate maintenance. The question here is how to reduce the loud noise characteristic of an air-cooled engine to a level commensurate with a water-cooled unit."

Honda's N360, a mini automobile equipped with an air-cooled engine, became Japan's best-selling model shortly after its release in March 1968. However, the research engineers had their doubts about using an air-cooled engine in a mass-production car. Therefore, to verify its feasibility they even went so far as to test air-cooled power plants in the T500.

Ultimately, there was no choice as to whether or not to adopt this approach. Developing a commercially viable air-cooled engine was a mission they were assigned to achieve.

Hideo Sugiura, then the head of the R&D Center, looked back upon the sentiment of the time: "We had a powerful company founder, who was on top of the engineering operation. He also had expertise, which he had acquired through a string of enormous successes. Having such a leader, the sentiment in the company was that we had to see it all the way through, regardless of where the road might take us. There was to be no surrender. We could not give up halfway."

"Streamlining the bulky construction of the air-cooled engine, and giving it the quietness of a water-cooled engine, will create the ideal power plant." With that concept in mind, the research engineers worked tirelessly to achieve their ideal. It was from this grueling process of trial and error that the DDAC (Duo Dyna Air Cooling) integrated dual air-cooled engine was achieved. The initial prototype was completed in July 1968, after which dynamic performance testing, temperature measurements and other basic evaluations were conducted.

The test results revealed the engine's susceptibility to heat, with higher temperatures measured in various areas of the engine. The oil temperature was also inordinately high.

"We must increase the output even further," they agreed. "Will this design really work?" There were many questions requiring answers, which would only come with time and effort. However, all this worried Kimio Shinmura, a chief research engineer supervising engine development together with Sugiura. So, after careful consideration he instructed Hisashi Tamai, who was in charge of engine design, to examine an alternative layout using a general-purpose air-cooled system, just in case.

Tamai, who had just returned from a long business trip in Europe, removed the research materials from the office so that they could experiment on the alternate approach without letting Mr. Honda know. For two weeks, he experimented with various layouts using a general air-cooled engine. Sugiura and Shinmura visited Tamai and reviewed the designs. But in time they had to conclude that the use of a general-purpose air-cooled engine would not provide an advantage over the integrated dual air-cooled engine in terms of weight and dimensions. Encouraged by the result, they turned their eyes toward the DDAC power plant.

Repeated testing and design changes uncovered many questions relating to operating temperatures, which at their extremes could cause the cylinders and heads to deform and create oil leaks throughout the power plant. Obviously, there were numerous problems to be addressed concerning engine durability.

Mr. Honda showed up at the R&D Center every day, issuing instructions directly to the individuals charged with various aspects of the project.

"Change the shape of the oil tank, so that it will enhance the airflow. Add fins, too, like this."

"Why don't you change it here, this way, to keep the oil from sloshing around inside the crankcase?"

One word from the company founder would put everything else on hold. Work began piling up.

"At that time," Tamai recalled, "no one could say no to the Old Man (Soichiro), and we even refrained from giving negative answers. It was as if we were actors who had to use our every resource to satisfy the producer."

Honda struggled onward, while in September of that year Toyota unveiled its Corona Mark II model, featuring a 1900-cc engine.

The Toyota release was not without ramifications within the Honda camp, however. In fact, it led to yet another change in the H1300's specifications: the target output was increased to 95 horsepower and the maximum speed to 175 km/h.

The research engineers, already inundated with work as the Suzuka Plant's mass-production date drew near, now had to cope with the endless design changes that came in throughout each day. Working from morning to midnight, they were forced to their limits, both physically and mentally.

Sugiura, no longer able to remain indifferent to his engineers' ordeal, set up a special desk in the Design Room. "Mr. Honda," he said with a tone of diplomacy, "please do not relate your ideas directly to the engineers, since it only confuses them. Please submit them to the special desk instead."

Assigned to this position was Yukiteru Mori, a senior research engineer whom the other engineers regarded as a "Big Brother." Mori's job was to listen to Mr. Honda's ideas and determine whether they should be accepted. In order for the engineers to concentrate fully on each design change - a process that required adjustments to engineering specifications used in mass production - Mori would prioritize Mr. Honda's various ideas before handing them over to the engineers.

Praised for Its Superior Engineering

Praise for the air-cooled H1300 was immediate. At a press conference held in October 1968, one reporter from the West German Autokritik magazine was barely able to contain his enthusiasm. "This is an ideal engine," he said, "the ultimate goal of an auto manufacturer. It will be sure to send shivers down the backs of automotive experts."

A crowd of journalists attended the H1300's press release held at the Akasaka Prince Hotel in Tokyo on April 15, 1970.

Later that year, at the Tokyo Motor Show, the new car had Mr. Eiji Toyota, president of Toyota Motor Industries (now Toyota Motor Corp.), standing in front of the Honda exhibit for a full ten minutes. The story goes that he then called in his young engineers and dropped a bomb, shouting, "Honda's car produces 100 horsepower with a 1300-cc engine. Why can't we do the same thing?" This and other examples from the time evidence the high marks the H1300 received for its outstanding engineering.

Soichiro Honda was justifiably proud and confident. Takeo Fujisawa, the vice-president in charge of management, also was optimistic about the H1300. Prior to the press release, Honda had invited the owners of approximately 4,800 Honda specialty stores to an extended general meeting to be held at the Suzuka Circuit over two months in September and October. The owners were also given an opportunity to visit the Suzuka Plant and see the new H1300. The event was a reflection of the strong enthusiasm Soichiro and Fujisawa had for their new model.

Continuous Design Changes and Reverse Operation of the Line

The H1300 project was in March 1969 progressing steadily toward mass production, leaving in its path a mountain of test parts. Accordingly, a resident office of the Development Department (R&D Center), called the SG Office, was created at the Suzuka Plant to support the transition. The office's task was to allow design engineers at the R&D Center to supervise the start-up process and make certain everything went as planned. Those in charge of engine design stayed at a nearby ryokan (traditional-style Japanese inn) called Uogi, where 15 or so engineers would crowd into the same room for the few hours they could spare in which to sleep.

The design and test engineers would get up bright and early each morning, visiting Suzuka's Engineering Department and factory floors to check the line quantity data and gather requests. Then, at about five o'clock in the evening, after reviewing the comments and data, they would begin modifying the design drawings. Although the H1300 production line was already in operation, numerous changes to the engine and frame were still being made daily. (At one time an average of 180 design changes were made each day!) Whenever a new drawing was completed, the persons in charge of the associated materials, engineering work and line sections were called to the SG Office. Too pressed for time, they did not even make a telephone call but headed straight for their suppliers to make arrangements. It was 24 hours a day continuous operation, making sure the delivery schedule was set and that fabrication started for each design change by midnight of the very day the change had been finalized in the drawing. With the cooperation of Honda's devoted suppliers, the production line continued to run without significant delays.

The SG staff, forced to burn the midnight oil day after day, began to suffer the pains of chronic sleep deprivation. Some of them could even be found falling asleep in the restroom. Yet, these conditions continued until April when Kiyoshi Kawashima, the president of Honda R&D, decided to postpone the car's release until May. Having seen the confusion taking place on the line due to frequent design changes, he halted the production line in order to make sure the latest changes were properly reflected in the finished product.

The basis for such a decision was Soichiro Honda's fundamental philosophy of customer satisfaction. Honda was determined to continue adding changes until the last minute-regardless of the sacrifices it meant for his employees-if doing so would ensure the best possible product. After all, it was a belief shared by those who worked on the production line.

It was ultimately decided that Suzuka's line would run in reverse; that the frame would be disassembled and the engine removed. A large tent was constructed adjacent to the engine plant. Within the tent, a manual line was created to accomplish this objective.

All applicable parts were changed to reflect the current design changes, while other parts were simply cleaned and returned to the line. The process of overhaul went on for more than a month. Tired and grimy, the employees worked to the limit in order to achieve what everyone wanted: a product that would truly satisfy the customer.

The H1300 assembly line at Suzuka. The smoothness of production was the result of numerous efforts on behalf of the designers, engineers, and workers.

Two new engine models were accordingly released in May: one representing the 77 Series, with 100 horsepower; and the other for the 99 Series, offering 115 horsepower.

The following month, upon the conclusion of their three-month assignment, all but a few SG staff members returned to the R&D Center.

The Genesis of Auto Production Technology

The TN360 mini truck launched in October 1967 was in production at Suzuka's automotive plant. However, adjacent to the TN line was a large vacant area, which when the plant was constructed was seen as the possible location for an expanded car-production facility.

Masaru Ohara, of the Suzuka Plant's welding section, was eventually reassigned to a station in the manufacturing machinery plant at Sayama (now Honda Engineering). The first employee to receive such an order, Ohara's task was to help establish a new production line for the H1300 full-featured small passenger car to be built in the area adjacent to the plant, then vacant. Ohara met with engineers from the Welding Department to discuss what form an ideal production line for a small passenger vehicle should take.

"We were so absorbed in our work," Ohara remembered. "But I just didn't know how it could be done. My colleagues were not sure, either. We collected reference books from overseas and studied them. Everyday was spent in discussions, with all of us sitting and debating the question."

"Probably because we were young, we were spirited and full of energy. We simply never gave up," added Ryo Arakawa, a welding engineer.

Brimming with confidence and ambition, they knew no one but them could do it. Gradually a production facility took shape, featuring a General Welding (GW) machine based on a completely new concept. Busily directing design revisions at the R&D Center, Soichiro Honda would drop by the plant every two months to see firsthand the changes taking place on the production floor.

One day, he saw six operators carrying frames on the line. "How can you let a person do such a meaningless job!" he shouted. "Do something about it by my next visit!"

The Welding Section was now under pressure, and the relevant personnel were called to an emergency meeting. Wracking their brains, they eventually created a device that hoisted the frame and carried it to the next process via a rail running overhead, along the line. When Soichiro next visited the plant, Ohara proudly showed him the system and said, "We corrected the problem you pointed out last time." Little did he know he would be the recipient of another thunderous volley from Soichiro.

"Damnit," Honda bellowed. "Of course those six people who were working here are not here anymore. But what about these people who must operate the hoist all day long? They have to baby-sit the engine enroute to the next step, then lower it, and come back here. They are nothing but housekeepers. Get rid of this system, right now. We cannot let valuable employees be consumed by such mindless work. Is that the best you could come up with?"

Mr. Honda's motto was " respect for the individual." At the same time, he had his own yardstick by which to determine efficiency. Not to mention the speed of the line, he was quite demanding when it came to cutting waste. He would not even compromise on issues such as the time needed to move things from one location to the next. At one time, he nearly covered the plant's concrete floor in white with chalk, drawing diagrams to teach the younger employees how to operate the line more efficiently.

One of the many distinctive features of the H1300 coupe released in February 1970 was the outer contour of its side body panel.

With the conventional N360 and the H1300 sedan, the side panel was built by assembling several components and soldering the joints. Yet, since a single pressed panel was subject to dimensional variations, smaller components were welded together and adjustments were made during the process to guarantee precision.

However, learning that the gas generated by soldering was harmful to the human body, Soichiro ordered the complete elimination of soldering. Accordingly, the development staff had to devise an alternative.

Therefore, following a series of discussions with designers at the R&D Center and production engineers from Suzuka and the manufacturing-machinery plant, the so-called "Mohican structure" was born. The basic idea of this structure was to form an integrated exterior side panel rather than the conventional split-type panel. Although the dies became a little more complex, the precision of stamping enjoyed a dramatic improvement. In terms of design, the product's appearance was also enhanced considerably. Moreover, the new structure yielded greater strength and productivity compared to the conventional panel.

The H1300 coupe employed the revolutionary Mohican structure

The Mohican structure is currently used by many automobiles around the world. Though the details have changed over the years, line number one in the welding factory built for H1300 production still maintains its original features, including the general welding machine, which is still in operation. Behind the facility's success are the efforts of those who have worked with the machine for more than thirty years.

"We knew it was going to become a production technology, not to mention an automobile manufacturing technology, for the future," Ohara and Arakawa recalled. "We didn't have robots then, so the industry was still relying on multiple-weld techniques. We had many problems, but the line operators learned so much by dealing with these problems. They learned by making and adjusting their own tools. It was the beginning of Honda's 'hand-made automation.' The H1300, our first car, contributed greatly by forcing us to create important production technology. Looking back, that model was the starting point for everything."

Retailer Expectations: Customer Response

Honda's automobile business was still struggling to find its way. Therefore, logically, many dealers had high hopes that they would be able to sell this "new car," which could not be obtained elsewhere.

"We believed we'd finally be able to sell a real car," said Hiromitsu Mukai, then the president of Mukai Automobile. "In fact, we had many customers who wanted us to sell regular cars. So, when I first saw the car I thought it would be a hit because its styling was far better than those of competitors."

Confident that they would soon have an extremely viable new product, Honda dealers used direct-mail advertising to contact potential users in the high-income group, such as business owners and doctors, who might be interested in upgrading their mini automobile or simply buying a new car. They were also quite active in product promotions. For example, they rented the entire Suzuka Circuit and invited their customers to the car's full-scale launch.

Despite such enthusiasm among dealers, though, the market reaction to the new car was severe.

"Looking back at it now, it would have been an enormous task to appeal to the mass market with a DDAC power plant," Mukai said. "Honda's obsession with perfection in engineering necessitated certain compromises in other areas, such as the heavy front end and uneven tire wear, which made it difficult for the sales side to promote the product to the public. The market simply was not ready for the car. The 99 series (sports sedan), however, was an excellent machine for the enthusiast. I know, because I used to drive one in rallies."

The unexpected irony is that complaints from the H1300 owners provided valuable lessons with which the mechanics could enhance their skills. They learned to identify the advantages and disadvantages of Honda models as compared to those of the competition, as seen through their customers' eyes.

In those days, Executive Vice-President Fujisawa was encouraging his dealers to develop original marketing strategies instead of simply conforming to directions provided by the manufacturer. In fact, he often talked of the dealers' management approaches, saying, "A company will lose its momentum once it begins to skimp on its work. But improve your quality as much as possible, and quantity will follow naturally.

The Switch to Water Cooling: A Meeting of Research Engineers in Atami

Every Honda employee in addition to Mr. Honda, who himself led the H1300 development project, was eager to see the company become a full-fledged carmaker. In fact, from the conception through production, Honda's original DDAC integrated dual air-cooled power plant was born out of that uncompromising effort, as a means of providing customers with the very best product. However, although their H1300 equipped with the new engine received rave reviews for its performance, sales fell short of expectations.

"Simply put," Sugiura remembered, "we didn't quite understand what kind of product the automobile should be. In a way, we emphasized individual components rather than looking at the total picture, believing that to combine the best parts would create the best car overall. Additionally, during development we did not pay sufficient attention to the customer's perceptions. We knew it was important, but the need to satisfy engineering objectives had ultimately won out. As a result, we neglected the most important measurement of quality and market value, meaning who was going to drive the car and how it would be used."

"Engineering is simply a tool by which we create a product the customer wants to buy. However, we became so zealous in our approach that we subordinated the car's original purpose. Instead, it all became an exercise in engineering, which was supposed to be a tool. That mistake was the most important lesson we learned from the H1300."

The H1300 did indeed provide many lessons, most significantly the need to consider the highest and best use a car would have rather than simply the means to engineer it. Eventually, the project changed the entire course of product development at Honda. In July 1969, nearly sixty employees of the R&D Center gathered in Karuizawa to attend a conference of research engineers. The conference had long been a regular activity, but this time the discussion was focused on "why the H1300 wasn't selling."

The purpose of the gathering, Sugiura said, was to "find ways of urging the Old Man to rethink his direction." The company's all-out effort had produced a new, air-cooled engine, but the unit's weight was a problem. As a result, vehicle weight increased and tire wear was dramatic. The engine's negative impact was evident in numerous areas, not the least of which was the issue of engine control amid the anticipated regulations on emissions, which were to be much stricter than before. Price, too, was a factor: consumers simply thought the car was expensive. It was not really an impossible chore to devise solutions to these problems. However, if they were to be corrected, the end product might cease to be one that ordinary customers would look to for their everyday needs. However, the highest hurdle was the new air-pollution regulations, which were soon to go into effect.

'There was a shorter, easier path we could take to satisfy the regulatory requirements. But why must we intentionally choose the longer, more difficult route?'

The engineers discussed everything they could think of, from every possible angle. Sugiura even invited Fujisawa to see the conference process in action. That night, over drinks, he told him, "These young engineers have certain problems. You might agree with Mr. Honda, but we do not think the air-cooled engines will work. Still, each time we give him our opinion, he rejects it outright."

Fujisawa learned that Soichiro Honda's philosophy had been disseminated throughout the organization, and that it had become the source of various difficulties. Therefore, he asked Sugiura to arrange a meeting at which the young engineers could present their views to the management of Engineering Operations.

The meeting took place in Atami in August. Having listened to the explanation given by Project Leader Tadashi Kume, Fujisawa was certain that Honda would lag far behind its competitors unless it shifted its focus away from air-cooled engines.

"Visit Mr. Honda as soon as the meeting is over," Fujisawa ordered Sugiura and his team.

It was a long, anxious drive from Atami to the Wako R&D Center. Having failed on numerous occasions to secure Mr. Honda's consent, the engineers had honestly hoped Fujisawa could talk to him directly. Nevertheless, upon their arrival at the Center, they went to Mr. Honda and told him they wanted to develop water-cooled engines, rather than air-cooled ones.

"Well, why didn't you come to me before speaking with Fujisawa?" Those were the only words Mr. Honda spoke. They did not hear from him after that.

The deadline approached for submission of the final design for their next model, the Life. This time, Sugiura and Shinmura confronted Mr. Honda again.

"Please let us design it with a water-cooled engine," they pleaded. "If we don't change course, we won't be able to satisfy the emission-control requirements." After a moment's silence, Soichiro Honda replied: "Do whatever you want, but make sure you take care of the water problems." Then he walked away.

"That was the moment I knew Honda was saved," recalled Sugiura.

Shinmura dashed to the Design Room to share the good news with his anxious colleagues: that the water-cooled engine had been given the green light. Meanwhile, Sugiura followed Mr. Honda and thanked him for making such a difficult decision.

The thing that had changed Soichiro Honda's mind, however, was a behind-the-scenes effort by Fujisawa. With that, the commanding officer of the entire engineering operation was compelled to see that the experience and dedication of his talented employees indeed merited consideration.

"Following the research engineers' assembly in Karuizawa as well as the Atami meeting, Mr. Fujisawa was certain it was the water-cooled engine that would hold the future," explains Kiyoshi Kawashima. "He then went to Mr. Honda and suggested that they should let the team try the water-cooled engine. However, Mr. Honda was insistent on using the air-cooled unit. Mr. Fujiwasa fully expected that answer."

"He then asked the ultimate question: 'Mr. Honda, do you want to stay with Honda as president of the company, or do you want to stay as an engineer?' After a period of silence, Mr. Honda said. 'I will stay as president.' Basically, that was his green light for the development of water-cooled engines."

The Lesson of the H1300: Establishing a System for Product Development

The H1300, with its constant design changes, was far from exemplary in terms of development. Amid the ever-increasing lineup of Honda car models and expanding scope of engineering, it was no longer possible for a single genius (Soichiro Honda) to run the entire operation. Instead, a team approach was required. If there were ten people on a team, each of them had to work together for the resolution of problems.

Kawashima, having learned a bitter lesson from the H1300 experience, then proposed the establishment of a development system and structural reforms for the R&D Center. Kume took the lead in designing the framework, the elements of which were as follows:

[1] The simultaneous, competitive development of dif-ferent models, along with the separation of D-development and R-research, including research of technologies previously unknown

[2] Promote participation of "sales" and "manufacturing" departments in the process from the start of development.

[3] Set "objectives and target requirements" for each product development.

[4] Establish a team-based promotional system.

[5] Implement S·E·D evaluation at each stage of devel-opment.

[6] Implement engineering evaluations as supple-mentary assessments.

The H1300 provided the shock needed to change Honda s operating structure. Under the new system, Honda introduced the water-cooled Life and Civic models as its new mini automobile and small passenger cars. The Civic, which was equipped with a CVCC engine in full compliance with the Air Pollution Control Act, drew the world's attention to Honda's superior engineering.

"All that pain we experienced is now a pleasant memory. The experience provided us with the ultimate learning ground for automotive development."

Those involved in the H1300 project agree unanimously. The pain indeed contributed much to the development of Honda's subsequent, highly successful automobile models.