Launching the S360 and T360 / 1962

The Concept of a "People’s Car"

"A four-seater with a top speed of 100 km/h, priced at 150,000 yen": This was the description of a car foreseen in an executive summary from the "People’s Car" concept, a promotional program announced by the Ministry of International Trade and Industry in May 1955. It immediately established the engineering target for those who would be creating the passenger cars of the coming era. Eventually several mini passenger models debuted in answer to MITI’s proposal, including the Suzu-Light (October 1955) and Subaru 360 (March 1958).

Honda’s S360 sportscar was unveiled on June 5, 1962, during the 11th National Honda Meeting General Assembly held at Suzuka Circuit, the construction of which was still under way.

Naturally, consumers expected Honda to join the trend and begin automobile production. However, Soichiro Honda remained somewhat cautious about the matter, offering his opinion in the December 1959 issue of the Honda Company Newsletter (Vol. 50): "We shouldn’t rush into auto production," he stated, "until we conduct thorough research and are absolutely confident that every requirement has been fulfilled, including the performance of our cars and production facilities."

Third Research Section: A Starting Point for Product Development

Nearly fifty engineers were hired by the Shirako Plant’s R&D Center from the end of 1957 through 1958, all of whom had prior engineering experience. Then, in September 1958, the Third Research Section emerged in preparation for car development. This section was to be responsible for all aspects, from product design through vehicle testing. In June of the same year, Motoo Nakajima of the Body Design Section, who was heading the group in charge of steering and suspension system design, received a rather unexpected call from Yoshihito Kudo, the general manager of the R&D Center. It was then that Nakajima was given an unofficial order of transfer to the Third Research Section.

The XA170 test car being brought into the repair shop at Fujiyoshida during a test run. During test drives outside the Honda premises, engineers were prohibited from wearing work clothes. Instead, they had to work undercover, like secret agents. (Photograph courtesy of Motoo Nakajima)

"Honda has decided to develop automobiles," Kudo said, "and I want you to be involved in development. This plan will be handled in strict confidence, for the time being. We can only assign a few people to the project, so be prepared to do more than just body design." With that, seven young engineers joined the new section. Their combined experience, though varied, was consistent with Honda’s goal as a new producer of automotive transportation. Some of the engineers were experienced in airplane development, while others had worked on three-wheeled vehicles during their employment at other companies.

Thus, did the Third Research Section become the prime force in car development at Honda.

The section’s initial task was to develop a mini automobile that would meet the "People’s Car" concept requirements. Drawings were issued in October 1958, and a prototype vehicle was completed the following January, going under the development code "XA170."

The XA170 made use of Honda’s renowned expertise in motorcycle racing with a forced-air-cooled, four-cylinder OHC V aluminum powerplant. Moreover, the FF car adopted a semi-monocoque structure with a flat floor so that it could be transformed into a sedan simply by adding rear seats. Since the prototype had been constructed specifically for test-drives, the fenders and hood were made with formed sheet steel. Patches of fabric constituted the sections where the roof and doors should be.

In the middle of the XA170’s test series, however, the team received an order from Mr. Honda himself for the development of a sportscar. Therefore, in the fall of 1959, the second prototype of XA190 two-seater was completed. Subsequently, the team took up the development of a truck, this time at the request of Senior Managing Director Takeo Fujisawa. It was an effort that ultimately led to the development of Honda’s XA120 mini truck.

Soichiro Honda had given the order to develop a sports car, because he thought it was better to create new demand rather than compete against more established manufacturers that already had a share of the market. He also believed that, as was the case with motorcycles, Honda should develop racecars and test them in actual competition in order to obtain as much expertise and knowledge as quickly as possible. This, he said, would elevate Japan’s automotive industry to a level of expertise and influence equal to the international manufacturers.

Fujisawa, on the other hand, suggested that the team develop a mini truck because he knew from society’s needs and market data that the demand for automobiles was mostly in the category of commercial vehicles. Furthermore, he had considered the fact that Honda would be selling its automobiles through motorcycle dealers.

An initial mini truck prototype was completed in the summer of 1960, after which it went through repeated tests in order to enhance the specifications. These changes resulted in the 2XA120 and 3XA120 units that followed. Therefore, while the development team’s main focus of research was the truck, the team members could not abandon their work on the sports car that Soichiro had requested. The two model developments continued through testing, and the specifications for each underwent considerable refinement.

Building an Industry through Open Competition

MITI, in May 1961, came out with a basic administrative policy regarding the automotive industry (subsequently the Temporary Measures Bill for the Promotion of Specified Industries, or the so-called "Specified Industry Promotion Bill"). It was a policy intended to motivate structural reform among industries nationwide, so that preparation could proceed regarding the expected liberalization of trade. The new MITI policy identified three domestic industries that were relatively less competitive in the global market [automobiles (passenger cars), special steel and petrochemicals] and gave them the "specified" designation.

MITI was ready to propose the deregulation of automobile imports by the spring of 1963, and in order to increase the industry’s ability to compete on the global stage, Japan’s auto manufacturers were classified into three groups. This, it was believed, would ensure effective guidance according to the characteristics of each group. The first group would comprise passenger cars from two companies; the second would include special products such as luxury models and sportscars, including two or three companies; and the third would be Japanese micro-cars, or mini automobiles, with two or three companies. Moreover, the bill set rules concerning mergers and acquisitions within the industry, thus limiting the entry of new companies.

Soichiro Honda described a previous discussion with Shigeru Sahashi, then the undersecretary at MITI, in a 1983 television interview that was later excerpted in an NHK broadcast of February 5, 1995, entitled, "The Men Who Built the Post-War Economy:"

"I deluged him with complaints," he said, "because I couldn’t understand it at all. To hell with the Specified Industry Promotion Law! I had the right to manufacture automobiles, and they couldn’t enforce a law that would allow only the existing manufacturers to build them while preventing us from doing the same. We were free to do exactly what we wanted. Besides, no one could say for certain that those in power would remain there forever. Look at history," Mr. Honda continued. "Eventually, a new power would always arise. I shouted at him angrily, saying that if MITI wanted us to merge (form a joint venture with another company), then they should buy our shares and propose it at our shareholders" meeting. After all, we were a public company. The government couldn’t tell me what to do."

Insisting that free competition would motivate the industry’s growth, Mr. Honda objected to the Japanese government’s measures, which were of course intended to foster the industry’s standing among the world’s car companies.

His objections, however, did not prevent MITI from submitting the bill to the Diet, and if it were to pass, the company would not be able to enter the business. It was a critical period for Honda.

Nothing is Impossible

Honda’s management, thus compelled to secure sufficient car-production records before the Specified Industries Bill could be passed, hurriedly sent an order to Honda R&D in January 1962, saying that development must proceed immediately. The plan was to develop two mini sports cars and two mini trucks, and to exhibit the prototypes at the 11th National Honda Meeting General Assembly (the so-called "Honda Meeting") scheduled for later that year.

The R&D Center’s targeted date of completion had initially been set for April 15, but it was moved to June 5 to accommodate scheduling of the new Suzuka Circuit’s preopening ceremony. On that day, the new models were displayed and test-driven at the Suzuka Circuit, even though portions of it were still under construction.

"The Third Research Section’s design team was originally made up of seven people, but by 1961, it had grown to around fifteen," recalled Masao Kawamura, the man in charge of exterior design. "At first, I was the only one in the molding group who handled automobiles, but by then that number had also increased, making it three of us. Since the company had decided to develop two models at the same time, that number was again increased to six, as a kind of emergency measure. So, there was a six-member mini truck team, and in order to push development it was divided into two groups."

The new prototype bodies were to be based on the previous XA190 and 3XA120 prototypes, which had already been tested and specifications were refined through numerous improvements. Although the team had the advantage of base models, they would still face the challenge of reflecting Mr. Honda’s detailed instructions in their progress.

Testing moved to the water-cooled, inline four-cylinder DOHC engine designated "XA250" following the discovery of certain limitations in the previous air-cooled engine. With this new base configuration they began developing two engine types for the two models, accommodating their respective body shapes and applications. Therefore, the mini sports car’s engine was given the development code "AS250" and the mini truck’s engine took on the code name AK250.

Kawamura, in preparation for the moment when the dummy model would be shown to Mr. Honda, had painted its body reddish orange for a highly appealing look. Upon seeing the dummy model, though, Mr. Honda announced, "The new car is definitely going to be red, but we should use a more vivid red." It was his assurance that the official development order would be forthcoming.

Kawamura, in eager response, painted the body a rich scarlet color and showed it to Mr. Honda a few days later, who liked it very much, and was obviously excited by the appearance. At that time, though, it was prohibited by law to use red or white on any auto body sold in Japan, since doing so might confuse it with an emergency vehicle such as a fire engine or ambulance. Therefore, to obtain approval for the use of red, Mitsugi Akita, then manager of the Development Management Section at Honda R&D, paid numerous visits to the Ministry of Transportation.

"Their response was cold and harsh, to be sure," recalled Akita. "The person in charge even said, ‘I know Honda, but I’ve never heard of Honda R&D." All the way back to the office I felt thoroughly depressed. I was even hesitant about seeing Mr. Honda. Days went by without any results, and Mr. Honda tried to promote his idea through the various media. At one time, he wrote a column for the Asahi Shimbun in which he said, ‘Red is the basic color of design. How can they ban it by law? I’m aware of no other industrial nation in the world in which the state monopolizes the use of colors.’"

Approval was finally granted, though, and with great excitement, Akita went to Soichiro with the news. To his surprise, however, Mr. Honda was quite calm. "Oh, that’s good," was all he said.

"It was only Honda who fought for the right to paint car bodies red," recalled Akita, "Soon, though, the other manufacturers started using it on many of their commercial vehicles."

Numerous people at Honda R&D had been mobilized in order to expedite last-minute adjustments to the car, continuing their work until the day before the Suzuka meeting. In fact, the final touch-ups were performed at the warehouse in Suzuka, and it was not until Midnight, June 4 that the cars were finally completed. The development team’s schedule had been extremely demanding, taking just four-and-a-half months.

"We relied on our youth and stamina to overcome impossible odds," Kawamura said.

Promoting Entry into the Car Business

The 11th National Honda Meeting General Assembly was held on June 5, 1962, at the soon-to-be-completed Suzuka Circuit. Product displays and test drives were also carried out on that date, with the S360 Honda Sports taking to the track with Mr. Honda behind the wheel. Beaming as he went, Mr. Honda blasted past the crowd that had assembled in the main bleachers. In the passenger’s seat, they could also see the face of Yoshio Nakamura, manager of the development project. This was Honda’s maiden voyage into the fiercely competitive waters of the automotive business. Yet, that endeavor, for all its challenges and difficulties, symbolized the pursuit of Mr. Honda’s lifelong dream.

The S360 exhibited at the 9th Tokyo Motor Show, 1962, attracted huge crowds.

The S360’s thrilling entrance was indeed impressive to the representatives of Honda’s franchised dealers who had gathered at Suzuka. They, after all, had strongly suggested that Honda manufacture cars. They wanted to have products they could sell during the winter months, when motorcycle sales experienced a significant decline.

The 9th Japan National Auto Show, a thirteen-day event, was held at the International Trade Center at Tokyo’s Harumi Wharf starting on October 25, 1962. Record crowds totaling over a million attended the show, amply demonstrating that the nation was ready to take on the car culture. There was Honda, proudly displaying its three new models: the S360 and S500 Honda Sports series, and the T360 mini truck. The company’s booth attracted throngs of people, sending a wave of anticipation across Japan and the world.

Honda had to act swiftly, now that the new models were out. What’s more, a record showing the sufficient production of cars had to be prepared before the passage of the MITI bill on specified industries.

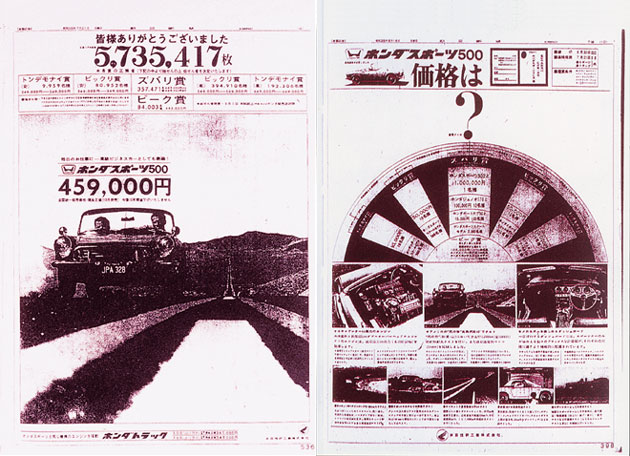

June 1963 saw a massive Honda sales campaign, which featured a high-impact advertisement in the country’s leading newspapers. The ad offered prizes to those who could correctly guess the price of the new Honda Sports 500. More than 5.7 million entries (the record for an ad of that type) were received. The price of 459,000 yen was subsequently announced in July, just a month after the ad had run. Surprisingly, that figure was much less than other makers were charging for comparable models. The T360 mini truck went on sale in August 1963, and the S500 sports car hit the market in October.

Honda’s newspaper ad for the Sports 500 Price Guess contest (right), and a subsequent article reporting the record 5.7 million entries (left) (Photo courtesy of Kyodo Advertising)

Despite a very favorable reception at both the Honda Meeting and the Tokyo Motor Show, the S360 unfortunately never made it to the market. Fujio Ishikawa, who was involved in the car’s body design at Hamamatsu Factory’s Welding Section, offered this explanation:

"When we were working on the car based on a 360 cc engine, the management told us to make the body wider to accommodate a 500 cc engine. Since there was only a limited demand for sports cars among the Japanese, it was suggested that we design a car that could be marketed around the world. I think Mr. Honda had been thinking globally from the very start."

A short time later, Kawamura got a call from Yoshio Nakamura, who was attending a planning meeting. Kawamura was told they wanted to widen the body by around 10 centimeters, and was asked whether the existing design could accommodate that degree of change. Kawamura told them the external appearance would not be affected if the extra width were accommodated around the center line. Therefore, Nakamura requested that the length be extended as well, saying the rear should increase by 30 centimeters.

The meeting resulted in Honda’s decision to focus on 360 cc mini trucks and 500 cc compact sports cars. This strategy was designed to qualify Honda as a manufacturer of micro-cars and passenger cars in time for the anticipated passage of the Specified Industry Promotion Bill. Moreover, the emphasis on small cars reflected the company’s intention to enter the world market.

The basic MITI policy regarding Japan’s car industry was compiled into the Temporary Measures Bill for the Promotion of Specified Industries in March 1963, and was submitted to the 43rd Session of the National Diet. However, the session was adjourned in July without a resolution. The bill was resubmitted to the 46th session starting in January 1964, but did not pass. The bill was eventually abandoned without anyone really knowing its ultimate destiny.

Production Encompassing Every Factory

Honda had been forced by the expected passage of the MITI bill to expedite its entry into auto manufacturing. Although the company had all the needed merchandising technology and expertise in quality control, certain basic requirements had gone unanswered, among which were the essential production technology and facilities for mass production of cars.

Honda’s facilities at the time were designed for motorcycle production, just a small portion of which could be used in the making of cars. Honda contacted its existing parts suppliers for help, along with several new suppliers, all the while investigating ways to utilize the existing infrastructure. Further, the layout of each plant was reviewed in order to secure the space needed for auto production.

Accordingly, it was decided that Saitama Factory (now Wako Plant) could produce engines for the T360 and S500, along with final assembly of the T360. Final assembly of the S500 would be handled by Hamamatsu Factory. The bodies for both models were built at Suzuka Factory for shipment to Saitama and Hamamatsu, while the differentials and transmissions were to be made at Saitama Factory and Hamamatsu Factory, respectively.

The Honda Company Newsletter (Vol. 93) of August 1963 featured an article in which Mr. Honda discussed his ideas regarding the construction of a dedicated auto production plant:

"They say Japan’s economy is stable today, but it’s still heavily influenced by the U.S. Now, Japan has its own automobiles, which is quite an achievement for a "semi-independent" economy such as ours. However, it would be very risky to rush into building a plant.

"We are now manufacturing sports cars in Hamamatsu and trucks in Saitama. However, we are asking our Suzuka Factory and manufacturing machinery factory, not to mention Hamamatsu and Saitama factories, to do their utmost to improve the quality of motorcycles, which are generating profits for us even now. We also want them to utilize their idle machinery, standardize parts and press-dies as much as possible, and do everything they can to utilize the existing facility [for car production]. We should consider building a [dedicated automobile] plant only when we are 100 percent sure that the construction of such a plant will bring us satisfactory results.

"We have become one of the world’s leading makers of motorcycles, and that should remain our foundation. We have to spend some time gathering various ideas that will improve our automobiles, just as we did when developing the Cub. And that’s what I want: an automotive version of the Cub."

The company’s widely dispersed system of production, however, involved every factory and was thus lacking in the efficiency Mr. Honda wanted. It did have certain advantages, however, since all factories were able to acquire some experience in car production. Those involved in production at the factories obtained invaluable insight by applying themselves to develop necessary solutions on a day-to-day basis. This experience at the beginning of Honda’s expansion phase was particularly useful in building Sayama Factory (now Saitama Factory’s Sayama Plant), and ultimately facilitated the launch of auto production at Suzuka.

Building Honda’s First Dedicated Auto Plant

The existing plants at Saitama, Hamamatsu, and Suzuka lacked sufficient scale and the facilities needed to implement real world auto production. Although they had mass-production lines, many critical processes were still performed manually. Accordingly, it resulted in new challenges, chief among them being higher costs.

Mr. Fujisawa explained the need for a dedicated auto plant in a January 1964 special edition of the Honda Company Newsletter:

"I believe we can only produce a combined total of 5,000 units per month, at most, for the T360 and S500, using the current facilities. So, to increase our volume of production, we have to expand those facilities."

Honda was busy looking for a suitable site for plant construction, but with a different purpose in mind: the company was planning to move its manufacturing machinery factory out of Shirako Plant. On September 2, 1963, the Manufacturing Machinery Factory’s Special Planning Office was formed, and the search for a site began in earnest. The staff set its eyes on the second candidate site in the Kawagoe/Sayama Industrial Park, located in Saitama Prefecture, and began negotiations to purchase a lot covering approximately 224,808 square meters.

Located on the borders of Kawagoe and Sayama, the industrial park covered an impressive 2,486,112 square meters. Moreover, it was close to the Seibu Shinjuku railway line’s Minami-Otsuka Station, close to the newly opened Metropolitan Belt Highway/National Highway Route 16. Furthermore, the planned Kan-etsu Motor Expressway was expected to further enhance park access. Since it was close to the city of Wako, it would be convenient in terms of land transportation and employee commuting.

The plan to build an automobile plant finally emerged during final negotiations for the purchase of the land. In February 1964, a special planning office was established at Saitama Factory in order to examine the possibility of building such a plant.

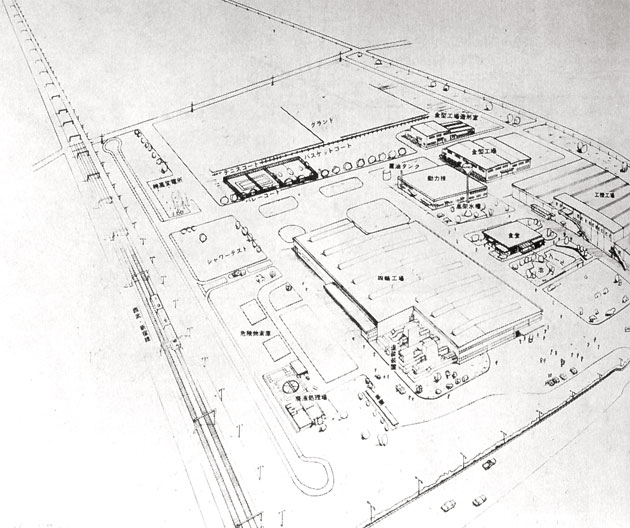

Sayama Factory’s layout

Several key conditions, however, were identified with regard to the construction of Honda’s first full-scale, mass production auto plant:

[1] Since a car has many parts (nearly ten times as many as a motorcycle), the location must be close to Honda’s key parts suppliers, who have been doing business with Honda since its establishment.

[2] The experience with the initial T360 and S500 production determined the need for a collaborative effort between the research/development side and the manufacturing side. Therefore, the location must be close to the R&D Center.

[3] The location should provide for easy distribution, facilitating the delivery of parts and shipment of completed cars.

The scheduled site of construction for the new manufacturing machinery plant satisfied all these conditions. The location would also ensure collaboration with the Production Engineering departments. For these reasons, Honda decided to build its automobile plant next to the manufacturing machinery plant. The special planning offices for the two plants were merged in June, the same year that the Sayama Special Planning Office was established. In anticipation of the auto facility’s future expansion the site area was increased to 380,190 square meters, an area four times that of Saitama Factory.

The overall concept of the plant was based on Suzuka Factory, a state-of-the-art plant with an air-conditioned, windowless building. To that were added specific requirements, such as a dedicated automobile plant. Just next to the automobile assembly plant (housing the welding, painting, final assembly, and final inspection lines) were the manufacturing machinery plant, which would make the production equipment used by the assembly plant, and the metal casting plant, which would accommodate future needs for in-house pressing, casting, and resin processing. Cafeterias, along with facilities for power generation and employee-welfare, were laid out within the premises, and the entire configuration was divided into three distinct areas.

The land was improved in May 1964, and construction began in June. The entire facility was completed in November.

"We had only a short time once the plan was finalized in order to begin the scheduled plant operations, so the work had to be rushed," remembered Katsumi Hosoda, a member of the Manufacturing Machinery Factory’s Special Planning Office, who was involved in the project from site selection through construction. "To meet the construction schedule, we visited the Business Enterprise Bureau of Saitama Prefecture every day, asking them to expedite certain portions of the Kawagoe/Sayama Industrial Park’s development plan. The requested work included the development of the plot purchased by Honda, the piping of a drainage main to the Iruma River, construction of access roads leading from National Highway Route 16, and the paving of roads around the Honda site. So, at the time Honda was ready to begin operating its plants, other plots were still under development.

"For employee commuting, we also wanted the Seibu Railway to build a new train station near the plants before they began operation," said Hosoda. "It wasn’t that easy negotiating with Seibu to ask that they accommodate our request."

However, the Seibu Shinjuku Line’s Shin-Sayama Station, temporarily housed in a prefabricated structure, opened on November 15. The manufacturing machinery plant completed its relocation from Shirako and immediately began operating.

In November, production of the S600 was transferred from Hamamatsu Factory to the new auto assembly plant. The first production car was completed at Sayama Factory on December 1, signaling the start of Honda’s first dedicated automobile plant. In April of the following year, T360 production, too, was transferred from Saitama Factory.

Sayama Factory was given a unique role among all Honda factories, serving as a dedicated final assembly plant for the production of automobiles.

Saitama Factory’s main assembly line churned out T360s at the rate of one every ten minutes.