A Product that Looks Good is also Good on the Inside / 1957

In May 1957, Honda underwent its sixth capital increase, which brought its capitalization to 360 million yen. Then, in August, the company created a revolutionary new product. This was a motorcycle that we should actually say was first imagined and then made. It was the Dream C70, which was put on sale in September of that year. It is slightly reminiscent of the NSU Supermax, made in Germany, which had an influence on it.

The Dream C70 was the first motorcycle to fully embody the appeal of Honda's creativity in everything from the engine to the styling. The unique style, called the "Buddhist temple" style, came into being under Soichiro Hondas personal direction.

However, this motorcycle already possessed the distinctive Honda character that Honda was seeking to express. It was the first bike to strongly capture that unique Honda personality.

The Dream C70 proclaimed with its entire being that it was a Honda product. The book titled Honda Engine Development: A Thirty-Year History proudly affirms that everything from the engine to the styling of this, Honda's first 250 cc twin-cylinder OHC, was "filled with original ideas."

Mass-production mid-displacement 4-stroke engines of 250 cc were dominated by the single-cylinder types at that time. There were hardly any twin-cylinder engines in existence. This machine was Honda's 4-stroke response to the 2-stroke twin-cylinder machines that had suddenly achieved improved performance and started coming to the forefront around that time.

The C70 was also the first product to take full advantage of the powerful machine tools in which Honda had invested 450 million yen. It could not have been imagined even a short year before that Honda would have the capability to create a world-class product worthy of exporting to the countries whose motorcycle industries led the world. And now its first such product had been born.

It was more powerful than Japanese 2-stroke machines in the same class, and its price was lower. It had a power output of 18 PS at 7400 rpm. This was Honda's first high-rpm, high-power motorcycle. It achieved such high revolutions that rumors even sprang up casting doubt on its durability.

Honda's first book, Speaking Frankly (Zakku Baran), contains the following passage:

"We put our emphasis on higher engine power. However, Honda increases power by raising engine revolutions, so some people seem to be criticizing our engines for being short-lived. Manufacturers that think this way might not get very long engine life themselves. If the engineering design is poor and precision is low, then the resulting friction will eat up power, so the efficiency is also low. If you try to force higher revolutions on an engine like that, it's bound to break down. But it would be wrong of them to say that, just because our engines would break down, Honda's must break down, too. If Honda engines are so bad, then nobody would be buying them, but the fact is, they are selling very well. Those manufacturers are using their own level of technology as a yardstick for measuring ours. They should stop that kind of petty behavior and confess honestly that they aren't able to do what we can do. Only then will they get to the point of realizing that they had better raise their own level of engineering. All they know how to do is suspiciously figure that a 4-stroke twin can't possibly be sold at that low a price, so there must be shoddy work inside it somewhere. People like that aren't experts in the field. When you come down to it, sham expertise is engineering's great enemy."

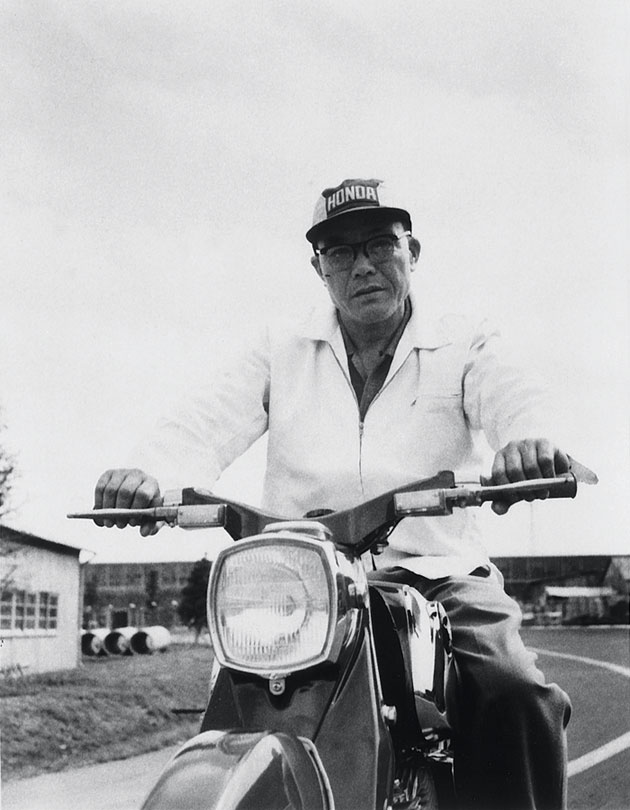

During that time, Mr. Honda led the styling design effort, working on the clay model with his own hands to create the unique angular frame body form that came to be known as the "Buddhist temple" style.

In aiming for the export market, they took pride in the knowledge that the Honda brand would effectively be representing Japan. Therefore, as Honda understood, it was vitally important for them to work out a uniquely distinctive styling. He took ten days away from work to visit temples in the ancient capital cities of Nara and Kyoto.

Sachi Honda was the only person to accompany her husband on this trip. She remembered:

"As usual, he didn't give a word of explanation about why we were going. Day after day, we visited Buddhist temples. One day, when we were at Sanzen-in temple in the Ohara area of Kyoto, he stopped still in front of a certain image of the Buddha. He didn't move, even when the temple visiting hours were over. He was so absorbed in it that one of the priests brought a flashlight so he could see it better. When I asked him why he had been looking at it that way, he just said to me, 'It has nothing to do with you.' Later, though, I found out what it was all about."

Mr. Honda himself said:

"I designed the lines on the side of the Dream C70 gas tank with a picture in my mind of the curve from the eyebrow to the nose on a figure of the Buddha."

Mr. Honda was so fond of styling work that the staff of the R&D Center's Modeling Room later nicknamed him the Modeling Chief. He would say that outward appearance mirrors the heart and mind, and appearance expresses the quality of the content.

The angular, formal styling design unified the look of the C70 all the way down to the engine. It was so popular in the marketplace that it gave rise to many imitations. The styling of the engine, in particular, which gives such a sense of precision, was even copied in later years for a certain Italian motorcycle. The engines in the C70 series seemed to embody the essence of aluminum die casting, and their design remains attractive even today.

Honda had long insisted on aluminum die casting because of its suitability for mass production, its precision, and its light weight.

During this period, his ideas at last underwent their full flowering. It should be noted in passing that when the Super Cub went into mass production, Honda had the largest share of aluminum consumption in the motor vehicle industry for production in Japan.

Following the C70, Honda entered its period of originality and creativity. It refused to copy anyone else, even if others copied it. The C71 that came next employed the self-starter that the company had gained experience with when making the Juno. The self-starter comes as a matter of course today, but Honda was the first to implement it.

In June of that year, Honda transformed its engineering design department into an R&D center located inside the Shirako Plant. This was a prelude to the formation of an autonomous Honda R&D Co., Ltd. Then in 1960, three years later, the Honda R&D Co., Ltd. was established as an autonomous entity separate from Honda Motor Co. There was no other instance at that time of a manufacturer making its R&D division into a separate company.

The "Jimmu Upturn" was over. Japan was in the midst of what people were calling "the pan-bottom economy," but Honda's bottom line kept improving.

The machinery that the company had imported was being used at a ferocious pace. Honda's two favorite catchphrases in the plant at this time were "Don't complain without even trying it first" and "Improve efficiency."

Isobe made a vivid record of Honda's countless workplace maxims, ranging from philosophical statements to concrete practical advice. One of these was:

"Equipment capability is determined by the maximum operating speed you reach."

The imported machinery was being operated at speeds that exceeded the manufacturer's recommendations. If these were engines, they were being run into the red zone. Naturally, malfunctions and overheating would occur. This way of working the machinery ignored the rated settings, and so Honda had to take countermeasures. The company had bought the machines so Honda owned them, and the company should use its intellectual abilities to make them into its own. Using stratagems that would amaze the manufacturers, Honda worked the machinery to the limit. For example, they handled overheating by attaching a radiator. A single-purpose machine was improved into a multi-purpose one. This experience led the company in the direction of fabricating its own machine tools. This ultimately resulted in establishment of the Honda Koki Engineering Factory in 1962.

In December 1957, Honda was listed on the Tokyo Stock Exchange. In March of the following year, it was also listed in Osaka, and then in April in Nagoya. In the process, Honda became the top domestic manufacturer in terms of motorcycle production volume.