Honda’s R&D Facilities Chapter 9

Honda’s R&D Facilities Chapter 9

2025.06.25

Indoor Omnidirectional Crash Test Facility: Proving Performance in the Real World

World-First Indoor All-Weather Omnidirectional Crash Test Facility

Honda completed its indoor all-weather omnidirectional crash test facility, a world first, in April 2000. The facility’s role is to check that vehicles achieve elevated, people-centric collision safety performance. This is realized through repeated collision testing in simulated real-world conditions of accidents that actually occur and by making the collision tests more comprehensive.

As a developer of mobility products, primarily automobiles and motorcycles, Honda wants customers to experience the joy of moving around safely and with peace of mind. The company wants to build a collision-free society where not only drivers and riders but everyone sharing the road can safely and confidently enjoy the freedom of mobility. This ambition is expressed in Honda’s global safety slogan, “Safety for Everyone.”

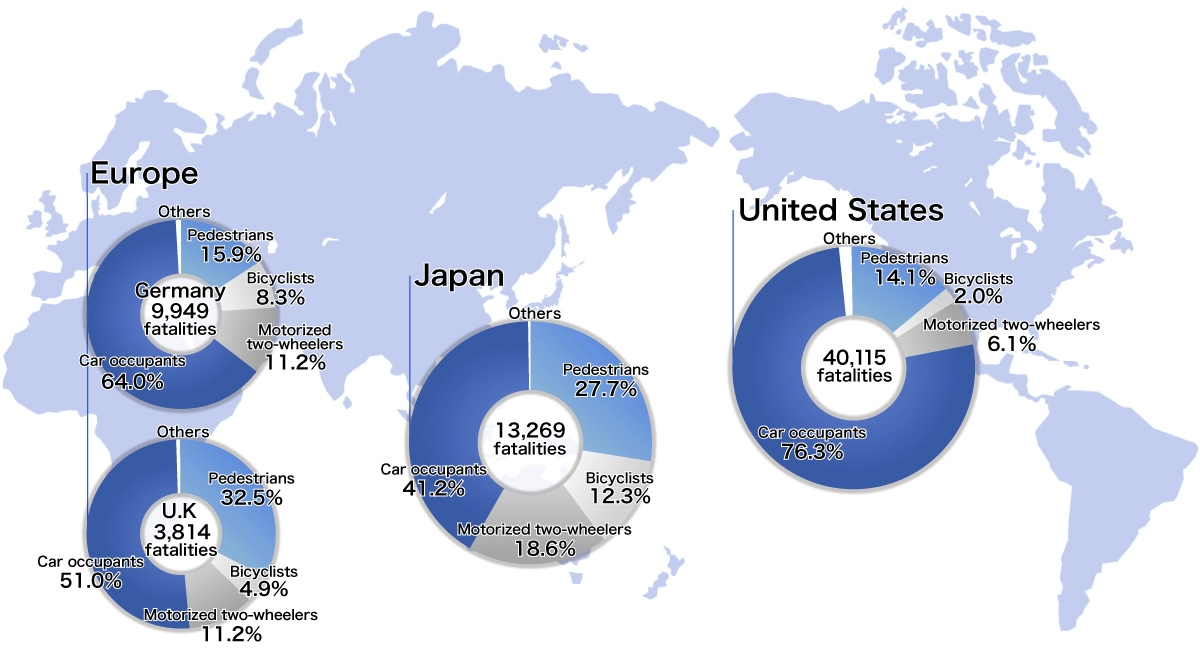

In keeping with this approach, studies were undertaken to determine the actual conditions of traffic accidents involving automobiles. We found a large percentage of fatal accidents were car-to-car or car-to-pedestrian collisions. The findings indicated the importance of paying attention to the realities. How do accidents happen, how do injuries occur…in the real world?

Road Accidents Around the World in 1993

Source: Road traffic statistics

Collision tests that broadly reflect the conditions of real-world accidents were not easy to perform. At the time, no automobile manufacturers had plans to build large-scale facilities of their own to carry out those tests. To Honda, legal compliance was not enough. Honda set out to achieve world-leading safety performance by independently researching accidents that were actually happening, establishing its own original standards based on the insight gained, and conducting tests accordingly. This was the motivation behind the construction of the world’s first indoor all-weather omnidirectional crash test facility.

A key feature of this facility is it is located indoors. Before the indoor omnidirectional crash test facility opened, Honda was able to conduct car-to-car crash tests at facilities belonging to outside parties. However, the testing schedule was dependent on the weather since the facility was outdoors. The indoor omnidirectional crash test facility literally allows testing indoors, enabling year-round testing regardless of the weather. The facility’s location within Honda’s Tochigi R&D Center ensures excellent access, contributing to greater efficiency in research and development.

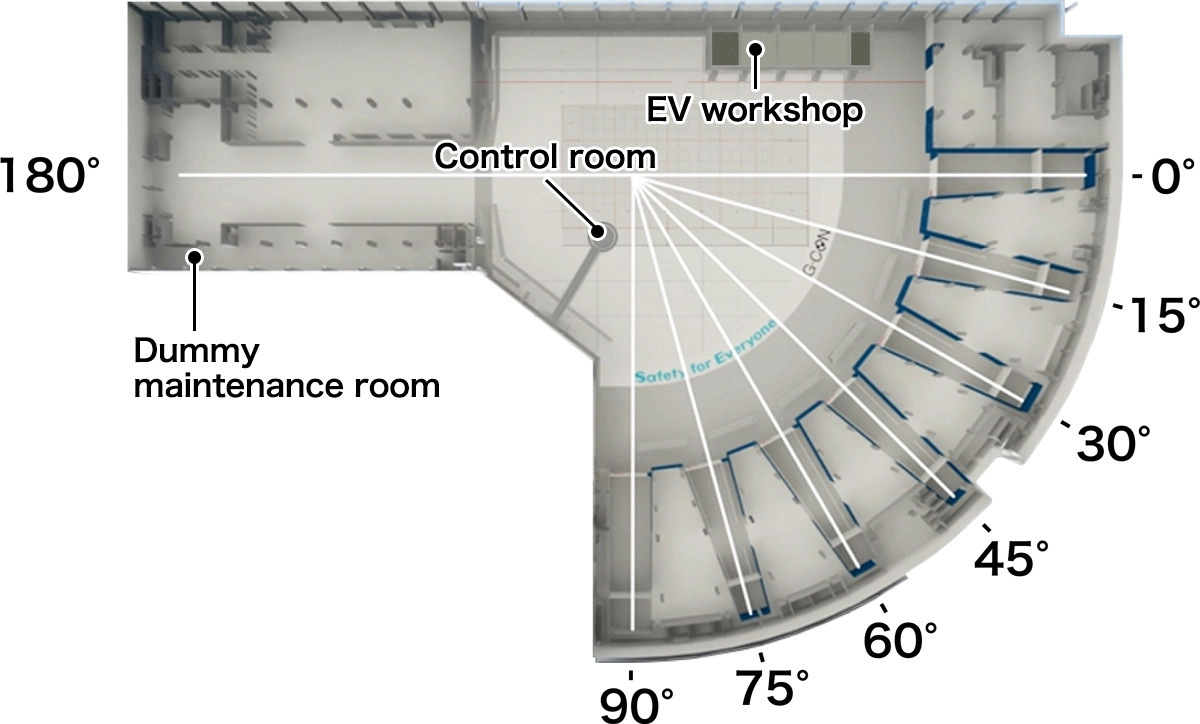

Facility Overview

The crash test area measures 272 meters north to south and 178 meters east to west. The roof height is 15 meters and there are no pillars across a 130-meter square expanse. Here it is possible to recreate real-world accidents. A total of eight courses branch out from a 0-degrees head-on collision course at 15-degree intervals (180-, 15-, 30-, 45-, 60-, 75-, and 90-degrees courses), enabling testing of collisions from any direction, including oblique frontal and oblique rear collisions, and side collisions, in addition to frontal collisions. Frontal collisions can be recreated with varying offset ratios. This includes 100% full-width collisions, and 50% and 25% offset collisions.

Indoor Omnidirectional Crash Test Facility Layout

To be able to accelerate up to 80 kilometers per hour while keeping crash test dummies in a stable posture, the length of each course was set at 130 meters. Here, it is possible to simultaneously pull along two vehicles at up to 80 kilometers per hour. It is also possible to create collisions between two vehicles traveling at different speeds, such as 40 and 60 kilometers per hour, or 40 and 80 kilometers per hour. The winch used to pull the vehicles is strong enough to pull a fully laden dump truck.

Test area

Test area looking between 60- and 45-degrees courses

Test area looking toward 0 degrees from the 180-degrees course

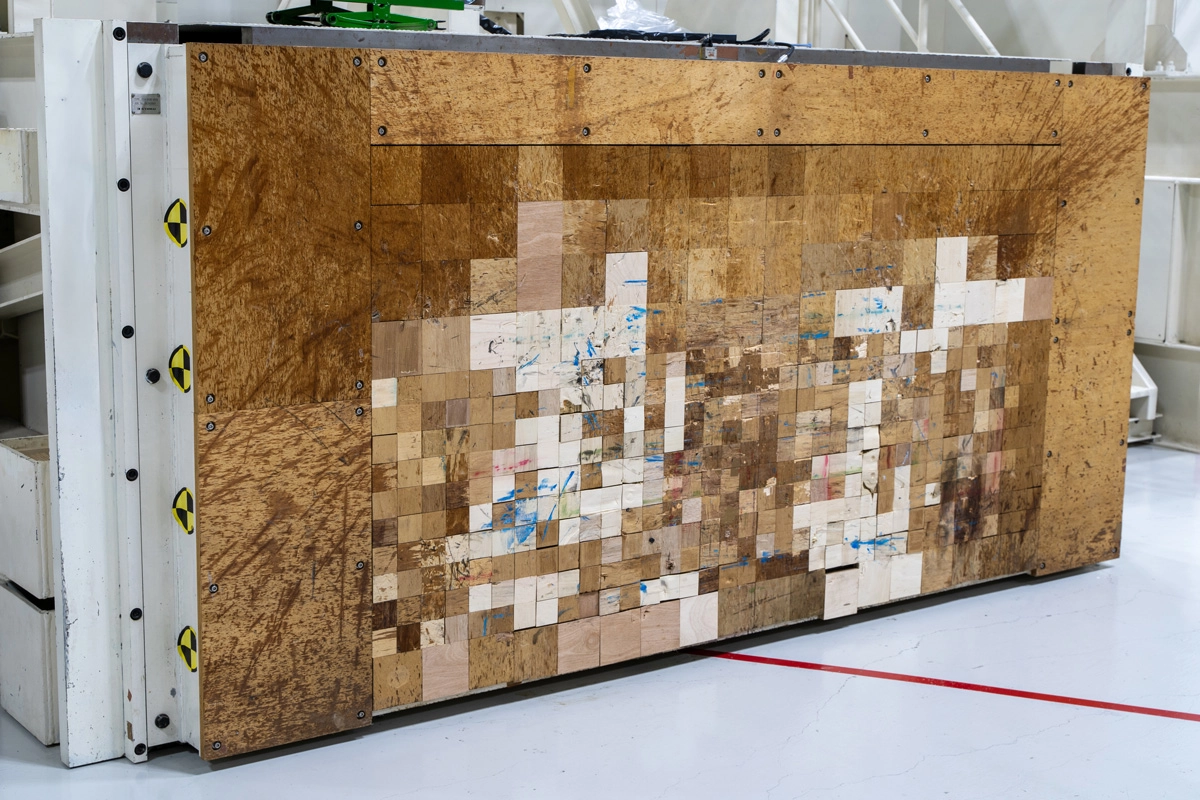

A Diverse Range of Crash Test Barriers

A wide range of collision scenarios can be recreated in the crash test area in addition to car-to-car collisions. They include car-to-motorcycle, car-to-pedestrian, car-to-fixed mobile barrier, and stationary car-to-moving barrier (Trolley type test equipment for crash test) collisions, as well as a dynamic rollover scenario, in which the car is made to roll over sideways. The mobile barrier unit, weighing 160 tons, moves to a specified position on its own using GPS. Moving barriers come in more than 10 variations to match country-specific protocols. Barriers have load sensors embedded inside them within small segments. Data obtained from collision tests is analyzed and fed back into research and development.

Mobile barrier unit

Mobile barrier wall face

Sensors are embedded in each of the square wall panels

Tires of the mobile barrier unit

Moving barriers

Rear collision test with a moving barrier

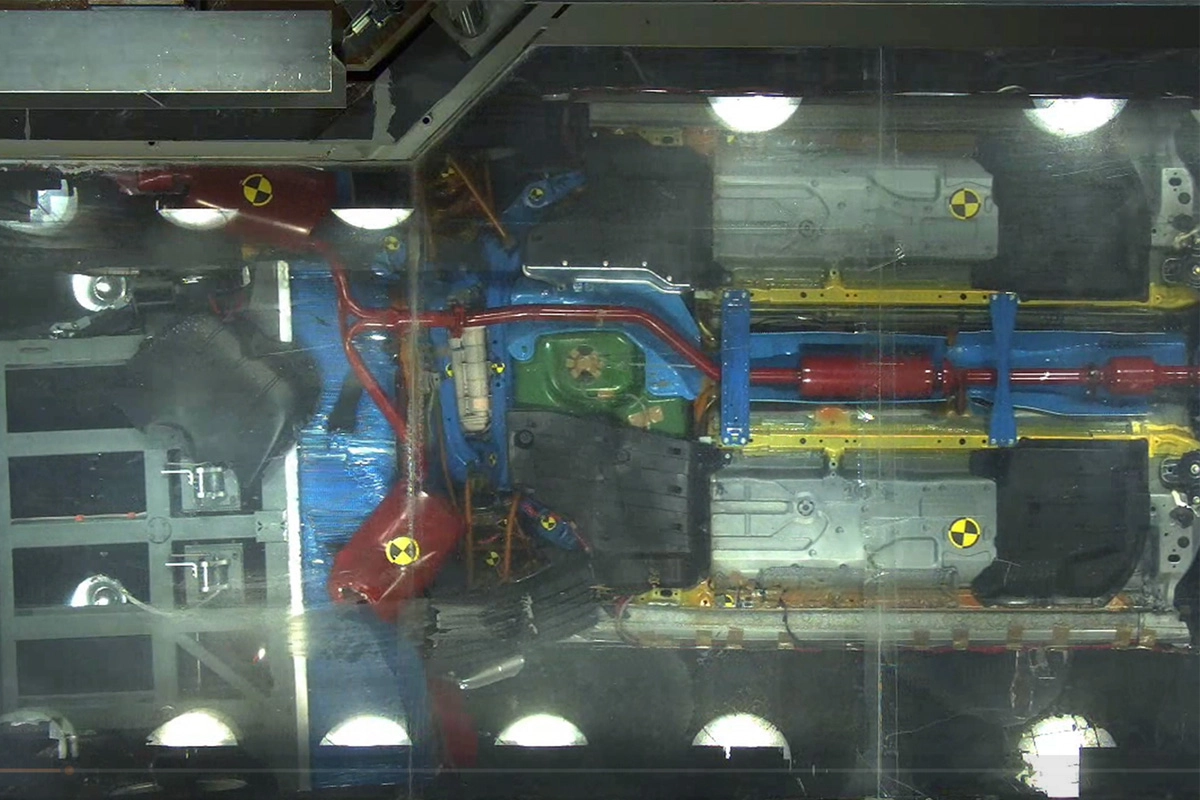

Rear collision test with a moving barrier (seen from underneath)

Dynamic rollover test

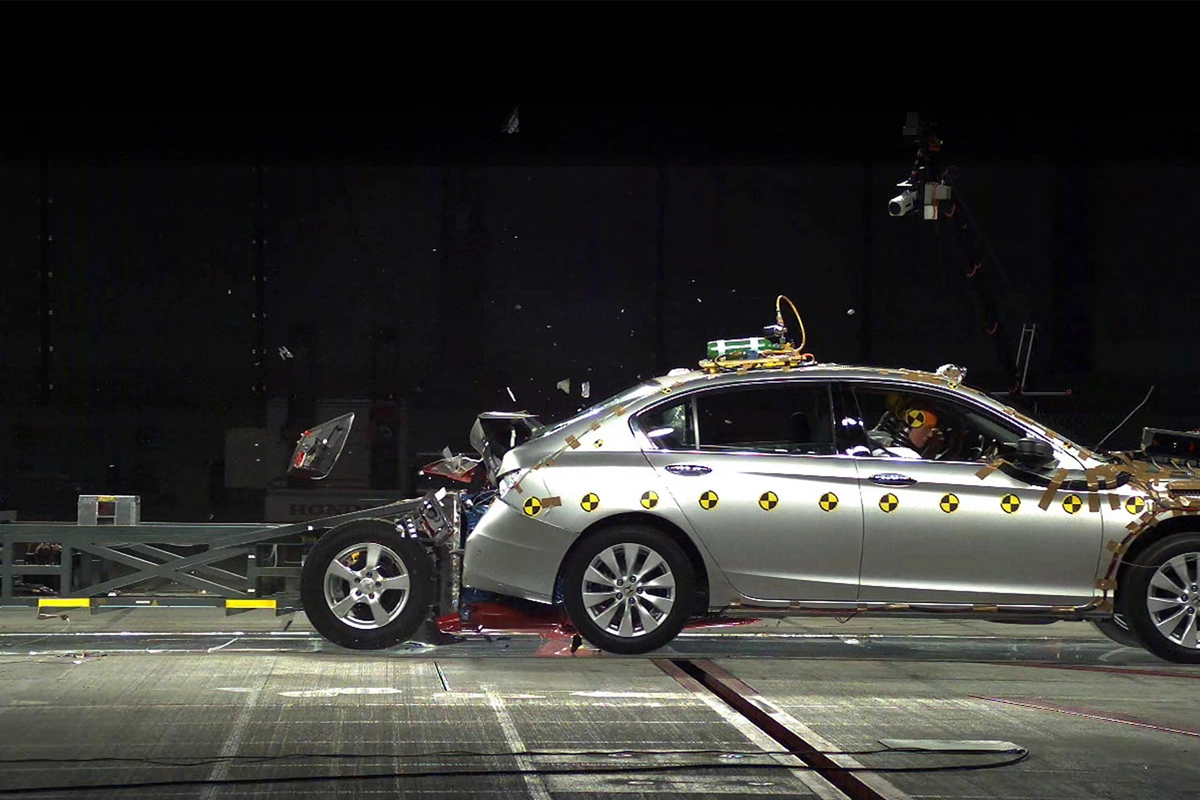

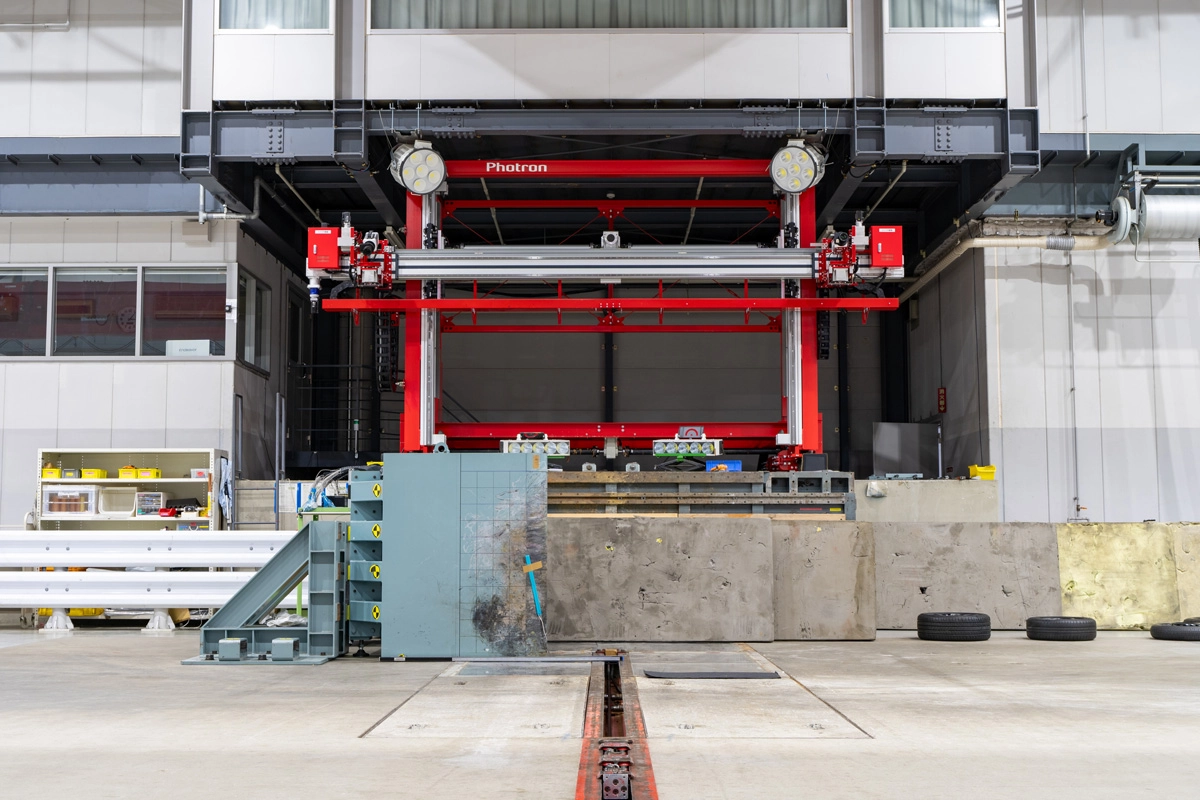

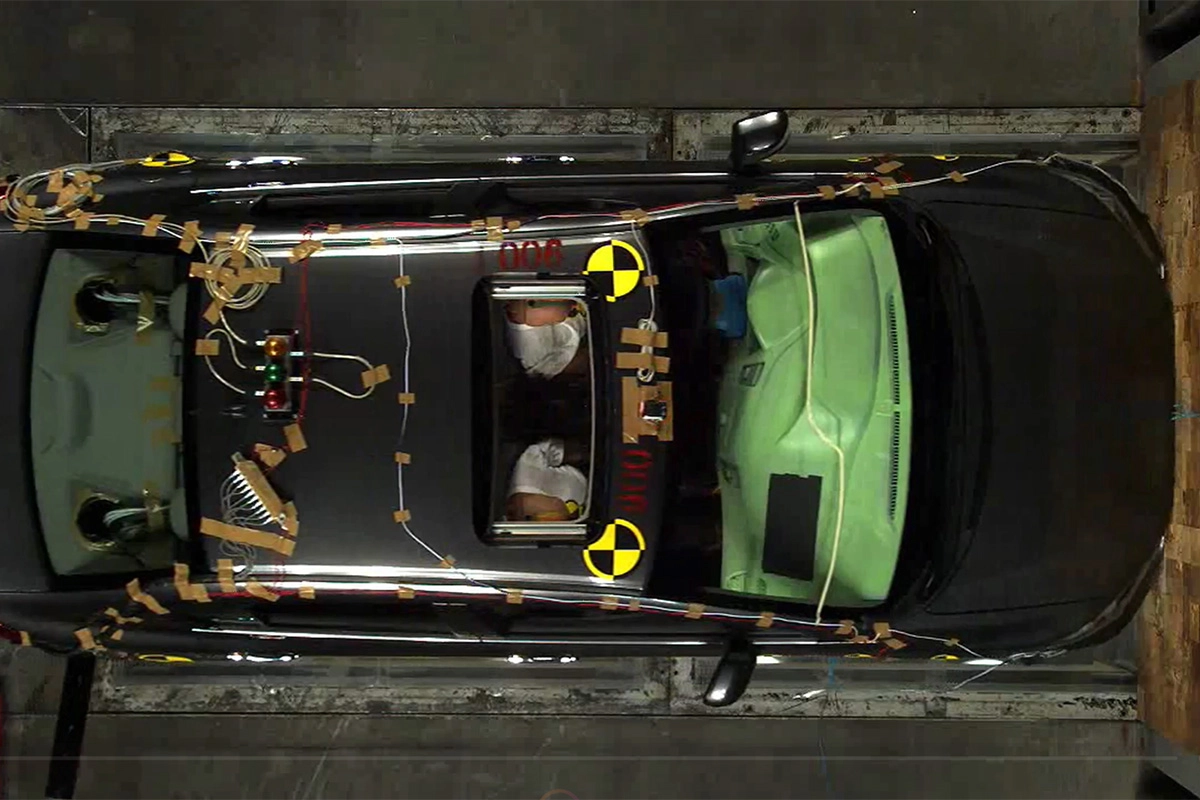

Recording of Collision Tests

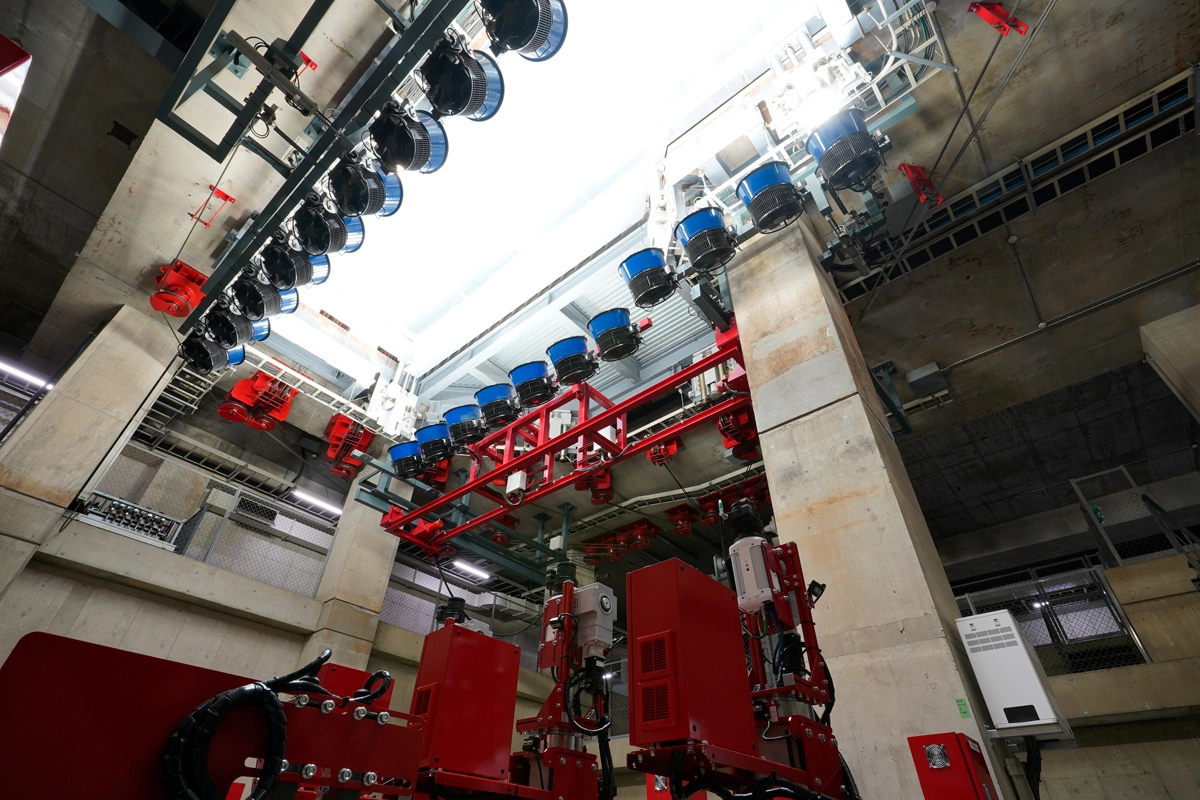

Automatically controlled high-speed cameras installed at the impact point and vehicle-mounted high-speed cameras combine to capture detailed video of the collision, including vehicle deformation and crash test dummy behavior at the time of impact. An opening in the floor at the impact point makes it easier to observe deformation on the undersides of the vehicles. This area of the floor can also be replaced with transparent acrylic panels. High-speed cameras under the floor are capable of capturing the condition of the vehicle underfloor during the collision test. Because the cameras need to be directed at the target from a distance to capture undistorted video, a deep space was built into the floor to ensure there was sufficient distance between vehicle underside and camera. Video captured by the cameras and the enormous volume of data gathered from crash test dummies are immediately forwarded to a computer server after the test to be applied to research and development. LED lights are used for illumination to ensure there is enough light available for high-speed video capture.

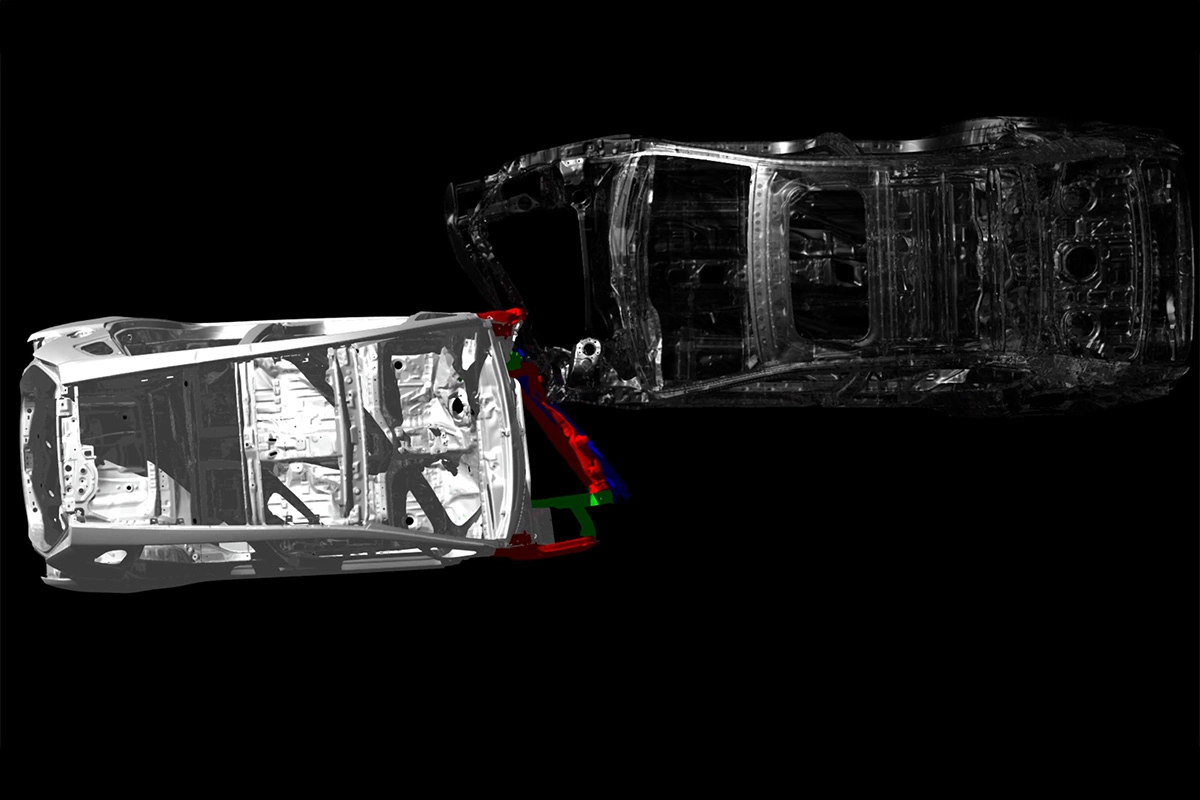

After a collision test, three-dimensional measurements are undertaken to collect data about deformation of the vehicle body. This is reconciled with simulation data to enable improvements to simulation accuracy and collision safety.

Test area

High-speed cameras

Acrylic floor panels

Space beneath the floor opening

Simulation data

Control Room

All control procedures for collision testing take place in the control room, which is suspended 4.5 meters above the floor to enable observation of all courses, and to ensure safety. The control room has sole charge of crash test-related controls, such as starting and stopping collision tests, lights, cameras, and opening and closing of shutters for conveying test vehicles in and out, and managing safety. Automated systems have been introduced to improve test efficiency. These remember collision scenario, lighting, and camera settings to shorten the preparation time when recreating similar tests.

Control Room

Control Room

Control Room

Electric Vehicle Collision Tests

The electric vehicle work area is a new area set up to cope with a rapidly increasing number of EV collision tests. Lithium-ion batteries used by EVs have inherent risks in that they may heat up or ignite when subjected to powerful shocks or physical damage. Honda vouches for the safety of battery packs integrated into its EVs, providing assurances that the lithium-ion batteries inside will not ignite. Nevertheless, EVs undergo measurement and maintenance work in a dedicated workshop just in case. If a fire does break out in this area, steps will be taken to prevent the fire from spreading. Once the fire is extinguished, a fork loader will be used to carry the vehicle outside the facility to be immersed in a special pool.

After collision testing, EVs sometimes undergo static rollover tests in the same way as vehicles with engines. Vehicles are secured to a static rollover test machine and made to roll over sideways in a full rotation. Vehicles with engines are checked for fuel leakage. EVs, e:HEVs (hybrid vehicles), and other vehicles equipped with drive batteries are checked for electrolyte leakage.

EV workshop

Fork loader

EV pool (pictured without water)

Static rollover test machine

Other Equipment and Features

The indoor omnidirectional crash test facility boasts a wide range of equipment and features outside of the crash test area. One example is the roof strength testing unit used to verify the strength of vehicle roofs in the event of a rollover. Other equipment includes a side door strength testing unit, for measuring the strength of vehicle doors, and a pedestrian protection testing unit that strikes an impactor simulating a person’s head against the vehicle hood.

A collision simulator is used for tests to verify the performance of airbags and seatbelts and to confirm the effects of countermeasures. The hydraulic collision simulation system with pitching uses a hydraulic piston to propel a sled on which the inside of a vehicle cabin has been reproduced. Through control of the hydraulic piston, the same deceleration profile as an actual collision are reproduced with high accuracy. Another feature of the simulator is that pitching can be hydraulically controlled to recreate the forward pitching of vehicles that occurs in actual vehicle collisions.

Just like in the collision testing area, high-speed cameras, for capturing the moment of the collision, and LED lights have been installed. The system supports not only frontal flat barrier mode, but also oblique mode, in which the collision occurs on a diagonal. There are four catapults for launching sleds. This allows for greater test efficiency as the test lead time can be shortened by completing preparations for the next tests in advance.

Roof strength testing unit

Roof strength test

Hydraulic collision simulator with pitching

Frontal collision test area

Frontal collision test

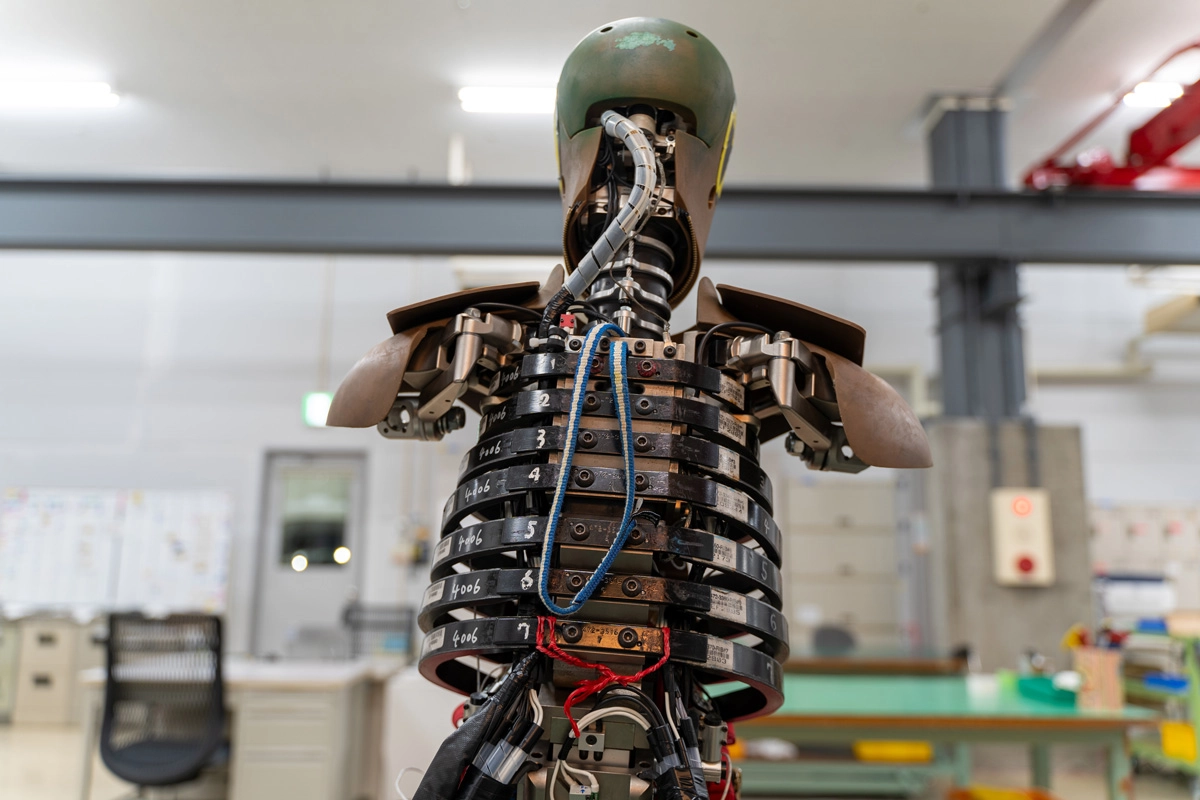

Crash Test Dummy Maintenance Room

The dummy maintenance room is where crash test dummies are examined to ensure performance meets specifications and where dummy maintenance is carried out. Dummies come in a variety of types suited to the different collision scenarios, such as frontal collisions and side collisions, and the parts being measured. There are also types that account for different types of size, genders, and ages. The most recent dummies have body builds more closely resembling the human body, and it is possible to measure load and acceleration, as in the past, as well as angular acceleration, which is thought to influence brain injury.

While dummies are generally used repeatedly, examinations are carried out around once every three tests. If obvious abnormalities occur or the dummy does not meet the specifications, parts are replaced or other maintenance is performed. Because the temperature range within which dummy performance satisfies regulations is stipulated, the dummy maintenance room is kept within predetermined temperature and humidity ranges throughout the year.

Dummy maintenance room

Various dummies

Dummy adjustments

Technologies Resulting from Use of the Indoor Omnidirectional Crash Test Facility

One result of using the indoor omnidirectional crash test facility has been the Advanced Compatibility Engineering™ (ACE™) Body now applied in all Honda models. Innovation in the shape and geometry of the frame prevents frame misalignment by absorbing the collision impact broadly across the surface. By dispersing the impact along multiple pathways, the energy of the impact is effectively absorbed. Thanks to this technology, the impact absorption of large and small vehicles is roughly the same.

Under the “Safety for Everyone” approach, Honda also develops its own original pedestrian dummies. Honda is researching technology for minimizing injury to pedestrians and carries out related testing. A representative usage case is the Pop-up Hood System. This technology uses a pressure sensor fitted inside the front bumper to perceive a collision with a pedestrian. When this happens, the rear end of the hood rises up, creating space between the hood and hard components like the engine, helping to mitigate the impact on the pedestrian’s head. In this way, Honda makes full use of the indoor omnidirectional crash test facility to realistically recreate a variety of accidents that could potentially occur on real-world roads. Through repeated updates based on insight gained from numerous collision tests and the demands of the times, Honda is working to further enhance collision safety in the real world.

INDEX

TechnologyHonda’s R&D FacilitiesIndoor Omnidirectional Crash Test Facility: Proving Performance in the Real World