Honda’s R&D Facilities Chapter 8

3D Metal Printing: Speedy Creation of Innovative Shapes

Honda’s R&D Facilities Chapter 8

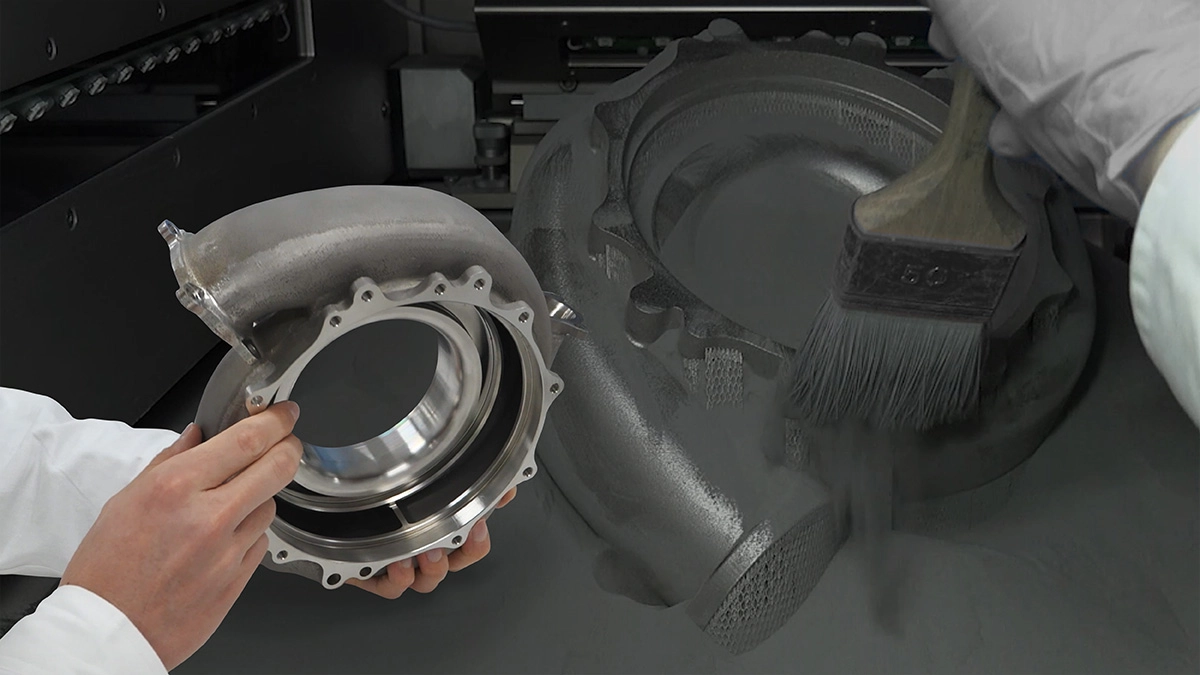

3D metal printing enables freedom of design

Honda is leveraging three-dimensional (3D) metal printing technology in development to add new value to its manufacturing processes and products. 3D metal printing enables greater freedom of design not premised on conventional methods of construction. It is suited to quick and efficient manufacturing of one-off items or high-mix, low-volume products, enabling faster and cheaper realization of unprecedented and innovative shapes.

Use of 3D printing enables items to be manufactured directly from design data, without needing molds, so the technology has the potential to help realize smart factories that drastically shorten the process from development to mass production. Honda develops a wide range of mobility options in diverse areas from automobiles, motorcycles and power products through to motorsports and aerospace, with 3D printing expected to be used in each of these fields.

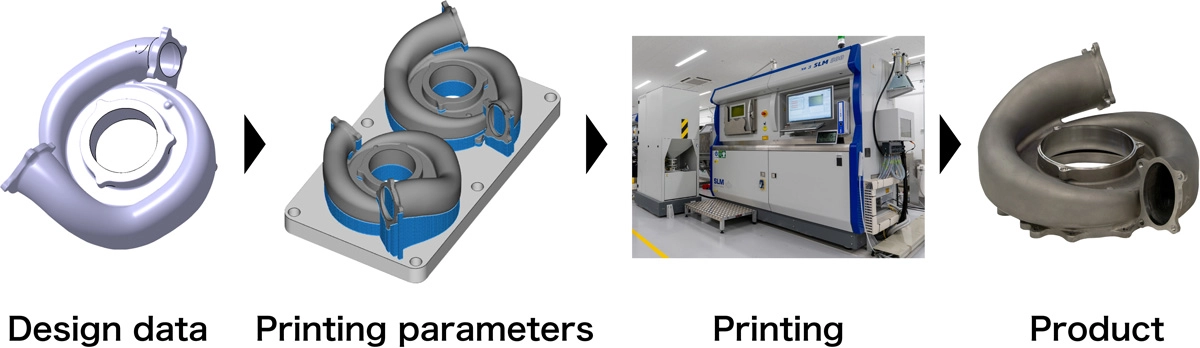

3D metal printing process

Additive manufacturing method (metal AM) using 3D metal printers

3D printers are manufacturing machines that perform a process called additive manufacturing (AM). As suggested by the name of this technology, they work by building up layers of a material to form a desired shape.

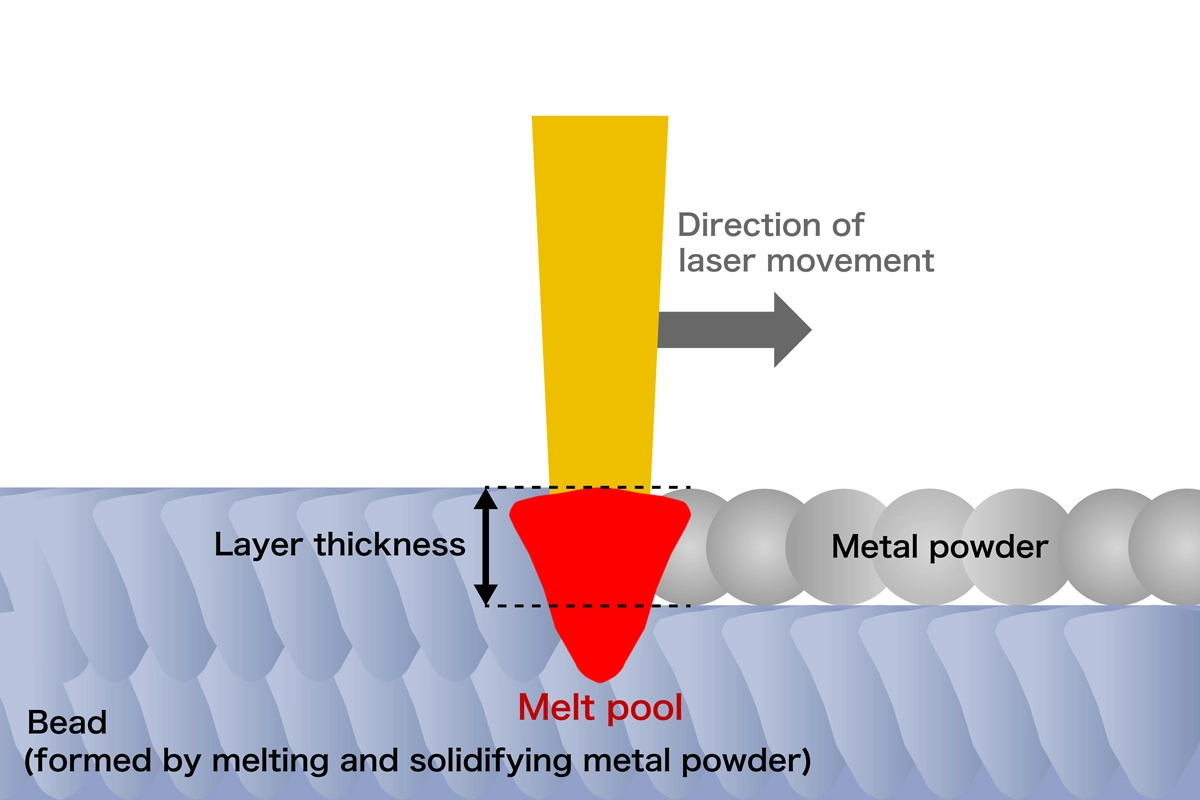

There are several different types of metal AM, but the one that Honda uses is called laser-based powder bed fusion (PBF). PBF lays down layers of metal powder on a base plate within the printing chamber, and then irradiates the powder by laser to melt and solidify the metal. Each layer produced by this method is only tens of micrometers (microns) thick (one micron is equal to one thousandth of a millimeter). As each layer is printed, the base plate drops down by the thickness of that layer and the recoater lays down another uniform layer of metal powder which is irradiated by laser again. This operation continues until the final 3D shape is created.

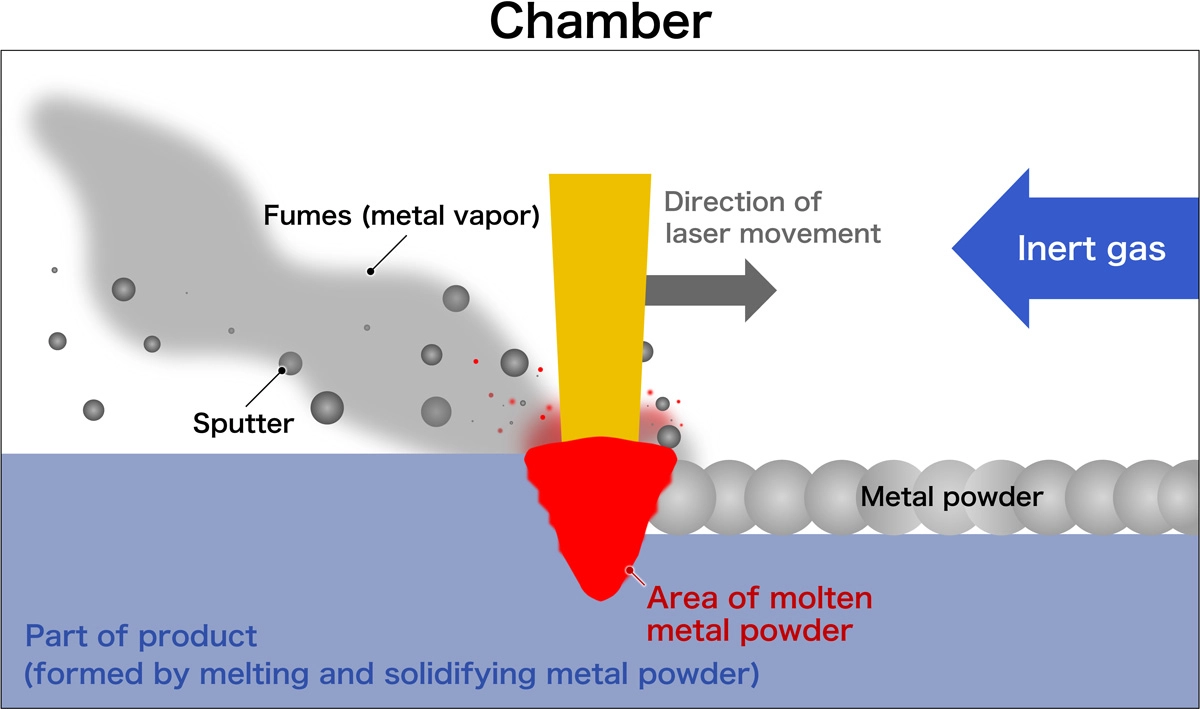

Printing principle

During laser irradiation, an inert gas is circulated within the chamber to create an anaerobic environment. This helps remove fumes (metal vapor) and molten metal sputter generated when melting the metal powder, which could hinder laser irradiation, and it prevents oxygen from mixing with the molten metal. Oxygen inclusion can cause porous metal and other defects.

Printing illustration

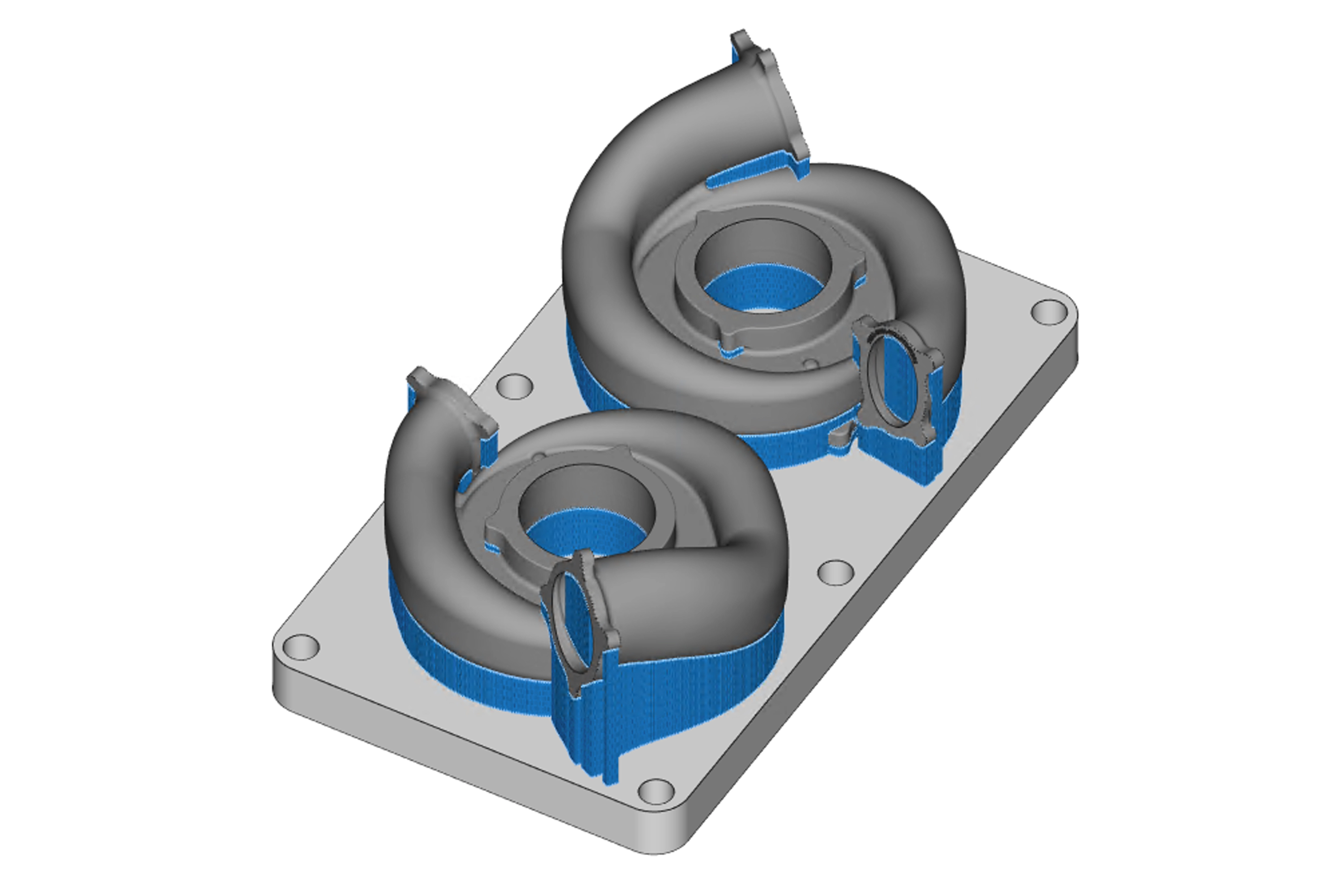

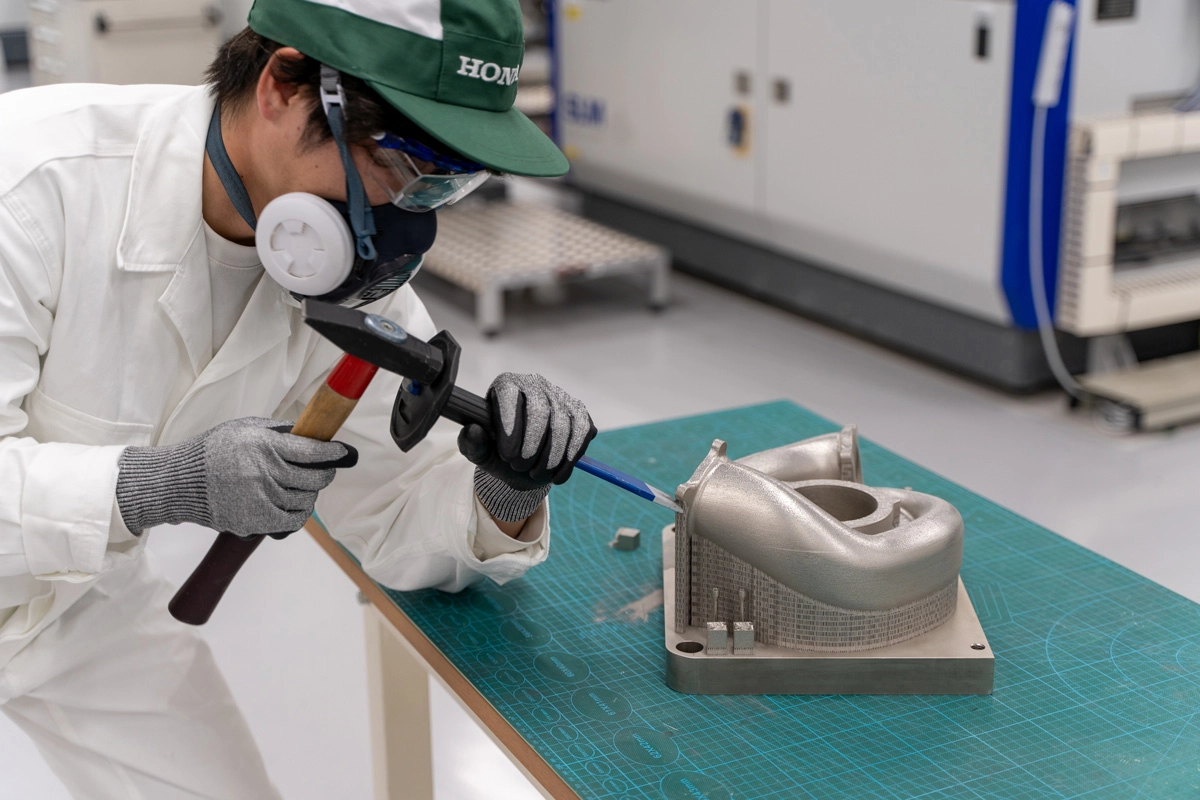

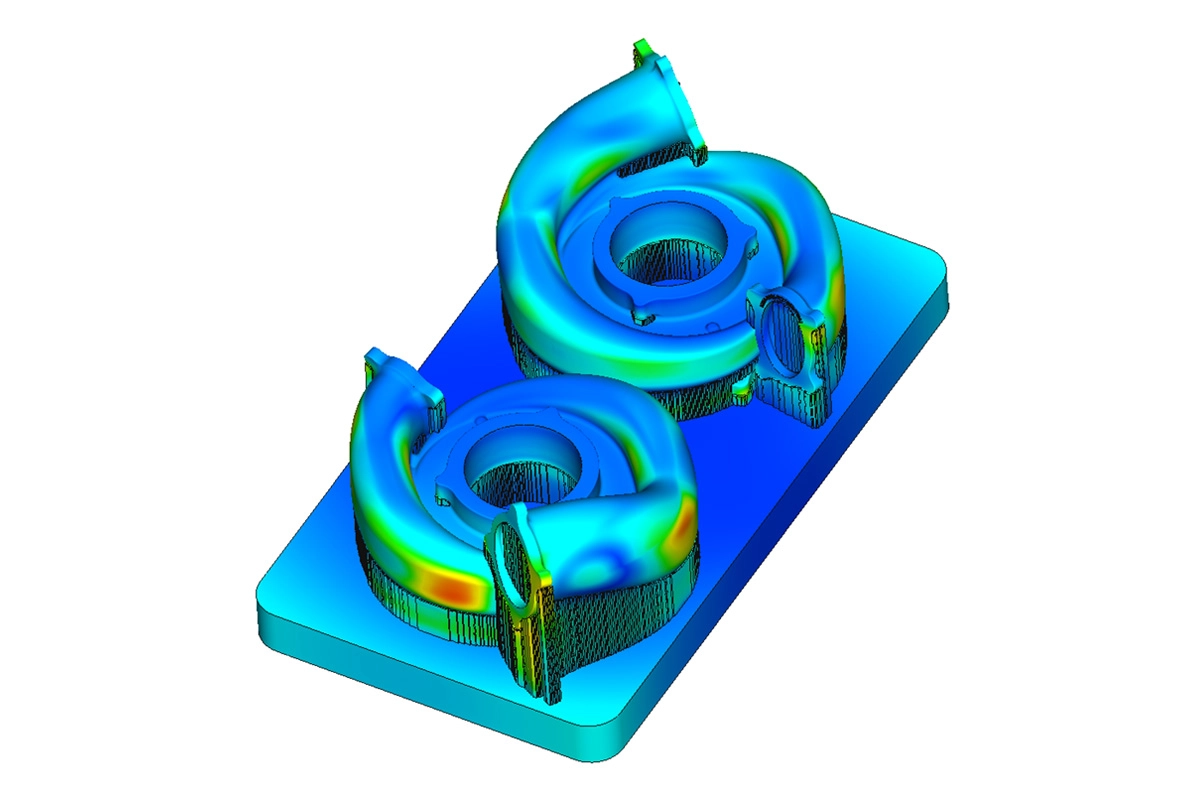

Metal AM has the ability to create complex shapes that are not possible with casting or forging technologies. However, as a product is being printed, there are parts that are suspended in the air, and adding further material to those parts can cause them to collapse. For this reason, support material must be added to the parts that are suspended in the air to create a supporting structure. This support material is removed in a post-printing process, so expertise is needed to efficiently manufacture a product with the minimal support material requirements and with the support material formed to facilitate removal.

Support structure review image

Product with support material attached

Removal of support material

Progress achieved through in-house metal AM operations

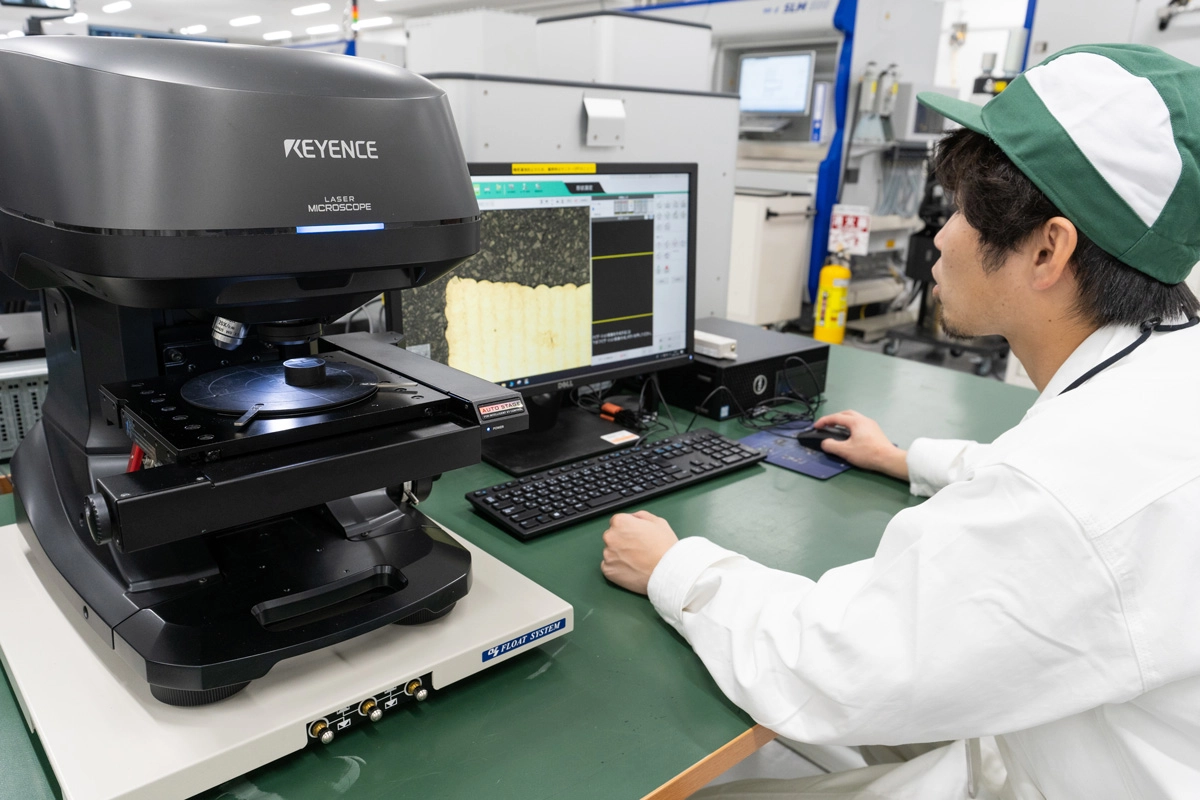

To improve quality and efficiency, a wealth of expertise is required in various printing parameters, including material condition, laser irradiation, inert gas circulation methods, and positioning of the product on the base plate. Honda conducts its metal AM design and manufacturing in-house. This has enabled it to develop its own expertise through operations such as parameter optimization by trialing various conditions, confirmation of molten metal states with layer-by-layer camera imaging, and confirmation of temperature and laser power output.

To optimize parameters, test pieces were placed on the base plate, various conditions such as laser output and scanning speed were tested, and strength was confirmed through tensile tests, before the optimal parameters were identified. Laser settings to properly layer the metal bead without gaps (selectively melting and solidifying the metal powder) are an important part of this process to identity optimal values. If the laser power is too weak, the bead is too small and gaps form due to bead-to-bead spacing and insufficient bead depth (layer thickness). If the laser power is too strong, on the other hand, not all gas generated is able to escape from the melt pool during irradiation, so it becomes trapped within the product.

Bead depth (layer thickness)

Confirmation of internal quality of test pieces

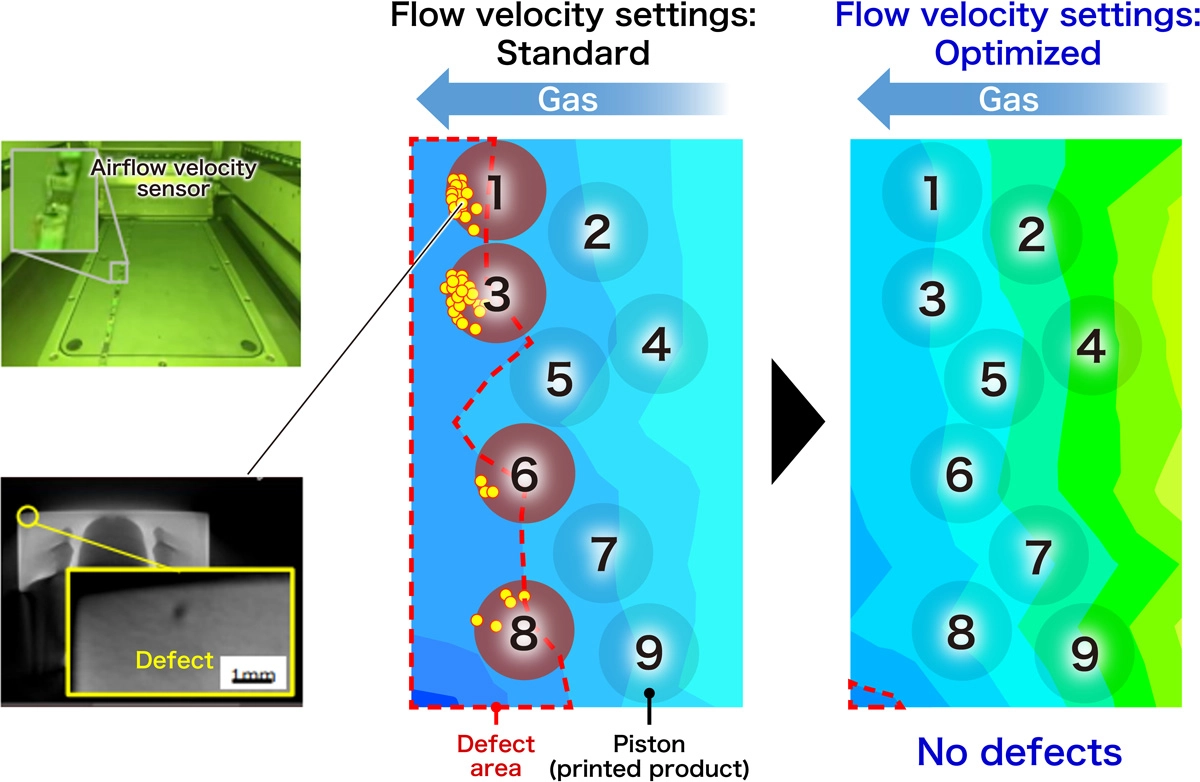

Progress has also been achieved on the productivity front. When transitioning from a printer with small printing area in the prototyping stage, to a 3D printer with large printing area used for the final products, Honda developers found that the greater the printing area became, the more susceptible the process was to external disturbances. For instance, flow velocity of the inert gas was slower on the downwind side of the system, which reduced the capacity of the system to remove fumes and molten metal sputter generated when melting the metal powder, and this insufficiency caused defects in the printed products on the downwind side. Studying the issue, the developers used a high-speed camera to confirm the status of sputter removal at each layer. They also used airflow velocity sensors to map velocity distribution and identify the cause of the defects. In this way, they were able to optimize flow velocity settings for the inert gas to ensure high quality at all points of the finished products.

Setting parameters for high quality through airflow velocity optimization

Using metal AM, products are printed by repeatedly laser welding through each layer, which are tens of micrometers thick, so products can deform easily. Traditionally, layers were printed then measured, and parameters were corrected based on those measurements. Through repeated corrections, this process achieved high dimensional accuracy. The downside of course was that it took a lot of time and prevented speedy production. Therefore, Honda developers introduced simulation-based deformation prediction technology to reduce time spent in trial and error. By incorporating deformation conditions into design, which is easy to do with simulations, they were able to optimize the printing approach and the support structure shapes to achieve speedy printing of products with high dimensional accuracy.

Simulation image

Checking results of simulations

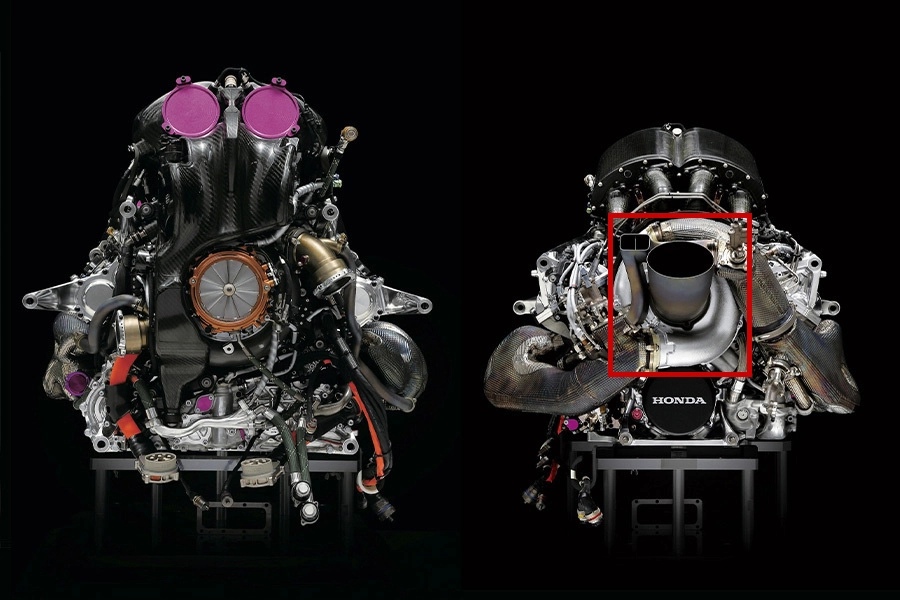

Case study 1. F1 parts (pistons and turbine housings)

One example of an application of metal AM technology is F1 power unit parts. Honda adopted metal AM technology to be able to quickly respond to specification changes that required complex shapes and thin-walled parts, which were not possible with conventional manufacturing technologies, while reducing manufacturing times and costs.

As one example of its application, pistons were traditionally aluminum forged parts, but Honda changed the material to iron, and used metal AM, to achieve the strength to withstand higher combustion pressures that came with development progress. While a change to iron, which has a higher specific weight than aluminum, generally results in increased weight, Honda was able to apply metal AM technology to achieve finished products that were actually lighter than ones manufactured using conventional technologies.

Another example was turbine housings, which were traditionally precision cast from Inconel, a highly heat-resistant nickel-based alloy. Turbine housings are larger than pistons, with areas of thin walls as well, so they suffered from a major issue of deformation during manufacture.

As mentioned already, Honda had acquired a wealth of expertise that helped it successfully establish metal AM-based manufacturing technologies for its pistons and turbine housings. It was also able to dramatically reduce manufacturing costs and lead times while meeting strict dimensional criteria. Honda adopted these parts for its racing machines from the middle of the F1 2020 season, contributing to its subsequent wins.

F1 racing car using 3D-printed parts

3D-printed turbine housing location

Piston

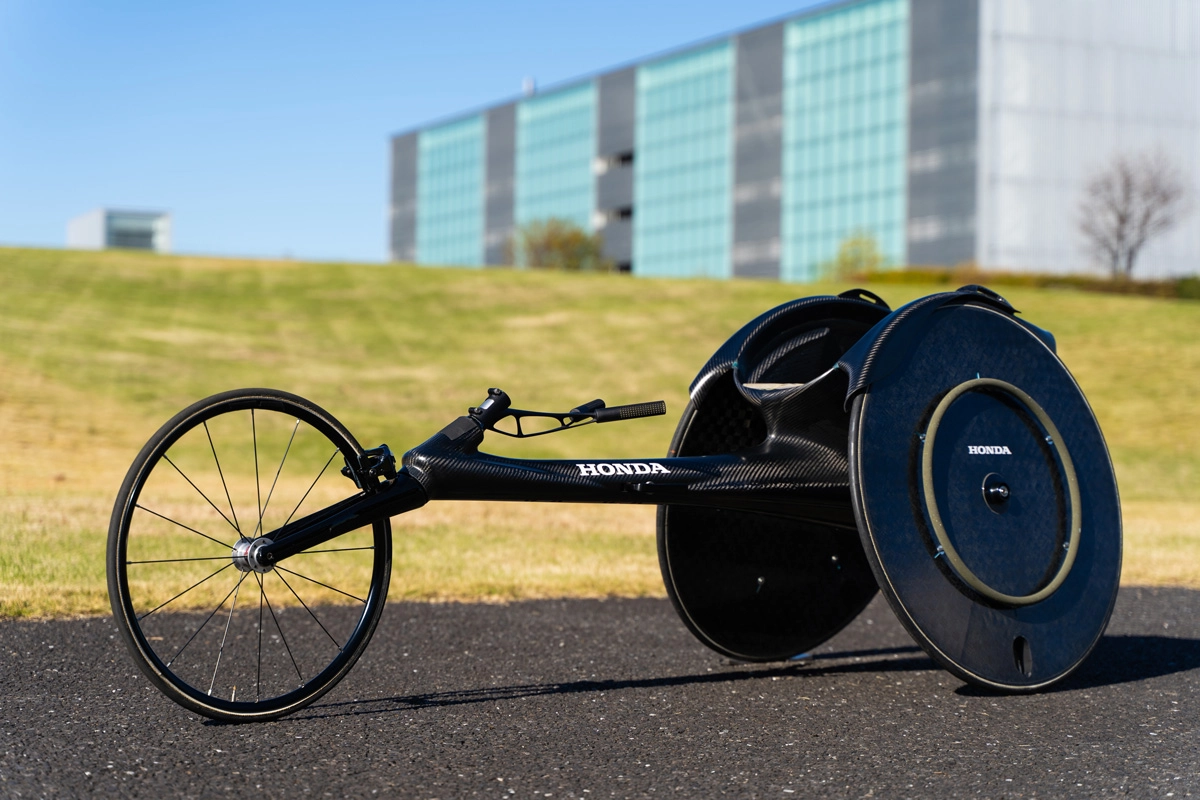

Case study 2. Racing wheelchair steering handle

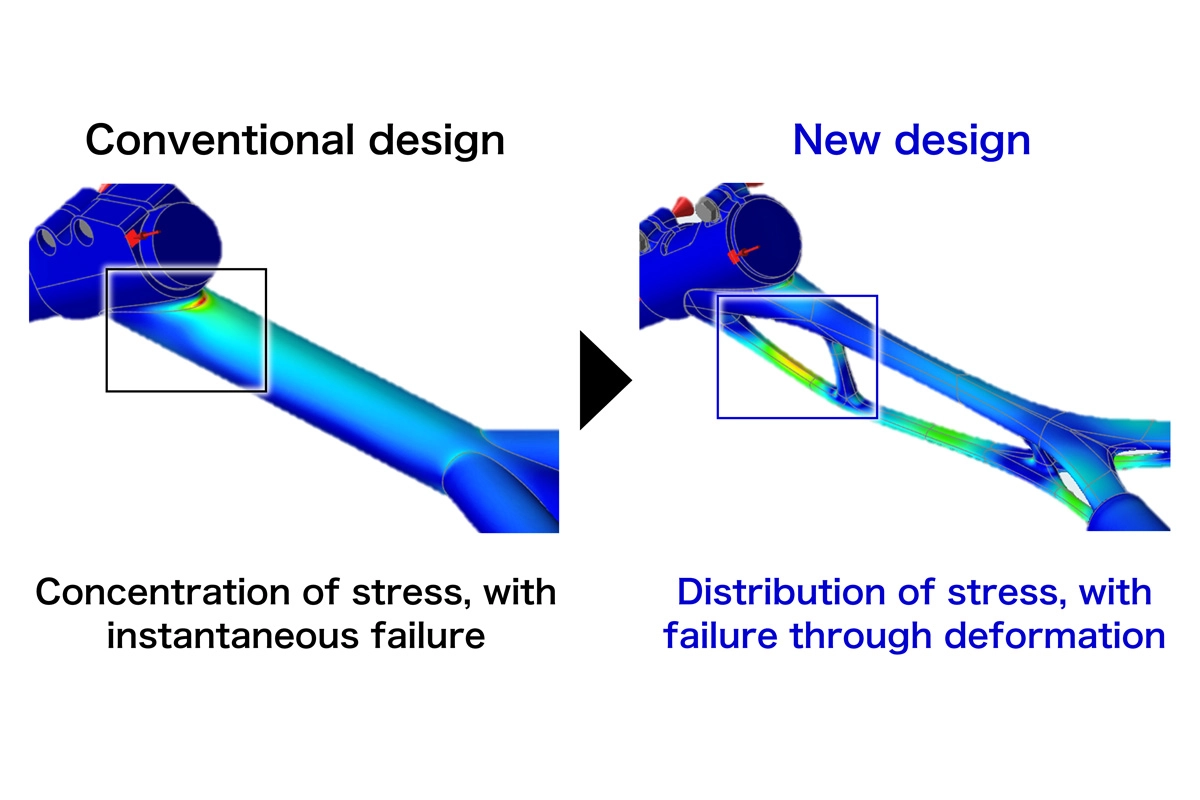

Honda is also engaged in the development and manufacture of racing wheelchairs. It used metal AM technology to create a special aluminum steering handle for athletes to steer their racing wheelchairs, with the primary goal being to reduce weight while ensuring collision safety.

The optimal shape of the steering handle varies according to the particular disability of each athlete. Traditionally, the steering handle was created as a welded aluminum pipe structure, which meant there were limits to creating a shape that matched the athlete’s needs. For this reason, Honda adopted topology* optimization during the design stage. Topology optimization is an analysis technology for achieving the most efficient structure for a given set of constraints.

After feeding the parameters into a dedicated program and conducting calculations, the software presented several solutions that stripped away as much unnecessary material as possible so that the remaining shape was all that was really necessary. From among those solutions, Honda selected one shape, with strength and lightness to meet the design requirements, that could be achieved through metal AM. In fact, the mesh grip section that contributed significantly to reducing weight could only have been manufactured using metal AM.

Through the design and manufacture of steering handles for racing wheelchairs, Honda was able to confirm the ability of metal AM technology to customize shapes to individual athletes while achieving weight reductions and ensuring safety. The other great merit of this technology is that, rather than the person having to fit the part, metal AM provides a high level of design freedom for shaping parts to fit the person. In other words, it makes it easier to meet the specific needs of users.

* Topology is a branch of geometry that studies the properties of shapes, and focuses only on the spatial relationships of consecutive points that make up that shape.

Racing wheelchair

Racing wheelchair steering handle

Results of structural analysis

TechnologyHonda’s R&D Facilities3D Metal Printing: Speedy Creation of Innovative Shapes