Honda’s R&D Facilities Chapter 3

Takasu Proving Ground: The Road Refines the Product

Honda’s R&D Facilities Chapter 3

Takasu Proving Ground

In 1990, Honda opened its Takasu Proving Ground in the town of Takasu (Kamikawa-gun, Hokkaido). Located to the north of Asahikawa City, Takasu receives a lot of snowfall, even by Hokkaido standards. In winter, the cold is extreme, sometimes dropping below minus 20 degrees Celsius. Snow falls from November to April, almost half the year. Takasu was chosen as the site for a new proving ground to take advantage of the ideal conditions for winter testing. The move consolidated the previously dispersed cold regions testing functions.

With courses including a circuit for evaluating the straight-line stability and quietness of vehicles that travel at high speed and a winding course, for assessing handling performance on winding mountain roads, the proving ground plays a role in refining the performance and quality of Honda vehicles to make them world-class.

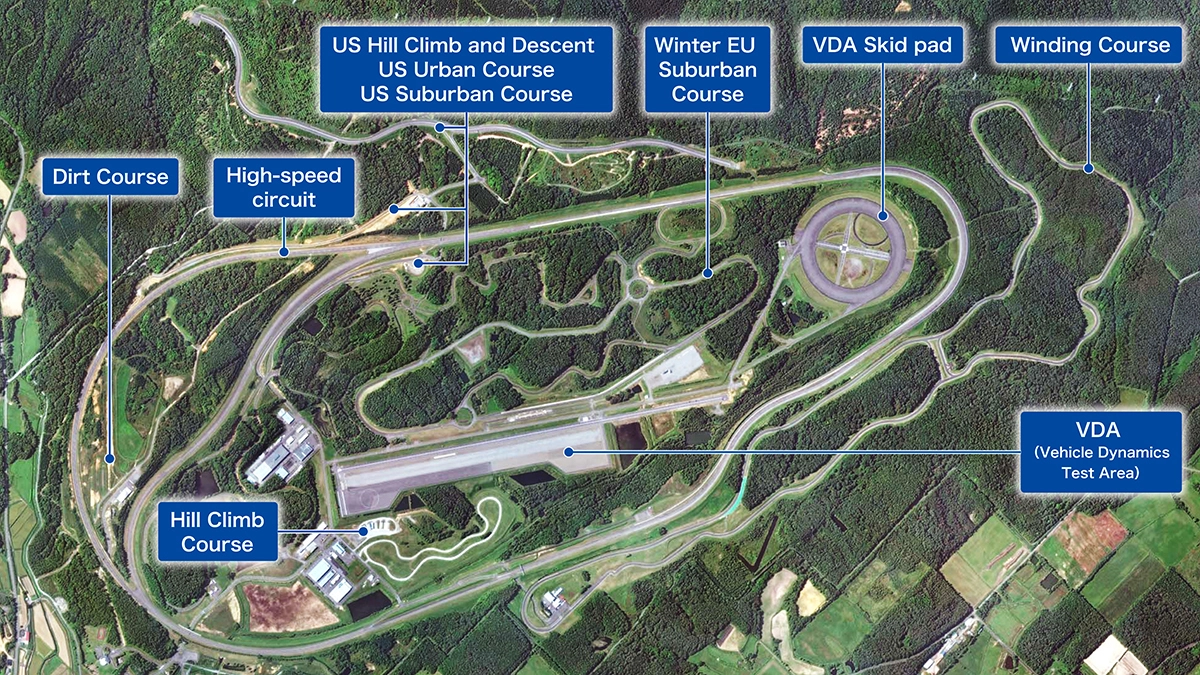

Takasu Proving Ground is vast, stretching across 7.89 square kilometers, more than five times the size of the 1.45 square-kilometer Tochigi Proving Ground. Within its boundaries are a high-speed circuit (6,820 meters); a European suburban course (13,923 meters); United States hill climb and descent (4,086 meters), Urban Course and Suburban Course (2,700 meters) courses; a vehicle dynamics test area (with 1,300 meter verification course and 500 meter skid pad); and a winding course (6,180 meters).

One characteristic of the Takasu Proving Ground is its faithful re-creation of roads all over the globe. There are 54 different types of road surface, recreating actual surface conditions, and even undulations, of roads in Europe, the United States, and Asia. It is part of a development cycle—Tochigi, to Takasu, to the end market—configured with fine detail. After honing basic performance parameters at Tochigi Proving Ground, Takasu Proving Ground is where dynamic performance is refined. The final evaluation takes place in the location of the end market.

Takasu Proving Ground (2019 photo)

High-Speed Circuit

Opened in 1995, the High-Speed Circuit recreates Germany’s Autobahn highway system, which has no speed limit in certain sections, as well as S curves with changes in elevation, as often seen on expressways in Japan’s mountainous areas, and the carpool lanes (priority lanes for vehicles meeting certain conditions, such as occupation by at least two people) of freeways in the United States. The reason the circuit has ups and downs and uneven surfaces is to ensure vehicles possess marketability in their performance at high speeds. In testing, vehicles are driven at speeds in excess of 200 kilometers per hour at times to evaluate characteristics such as dynamic performance and driving comfort, which need to be tested at the very limits.

High-Speed Circuit

High-Speed Circuit (winter)

EU Suburban Course

The EU Suburban Course has roundabouts—circular intersections without traffic lights—and the same signage you would find in Europe. The aged suburban roads of Germany and the United Kingdom have also been faithfully reproduced to create a realistic environment. This course is primarily used to test vibrations and noise off the road surface in order to assess and refine sensory value, such as driving comfort.

EU Suburban Course

US Hill Climb and Descent / US Urban Course and Suburban Course

The US Hill Climb and Descent and US Urban and Suburban Course were newly established in 2018 to enable similar testing in Japan as would otherwise take place within the target market of models developed for North America. Until then, field testing of production models for North America took place outside Los Angeles. That course had consisted of four areas: urban, hill climb and descent, suburban, and high-speed.

The urban area consisted of a continuous straight road interrupted only by intersections. Though the vehicle speed was low, the course required frequent acceleration and deceleration. The hill climb and descent area had ups and downs and vehicles had to round curves with small turning radii at higher speeds than in the urban area. Sections with turns along roads that rose and fell allowed combined evaluation of powertrain and handling performance. In the suburban area, vehicles had to travel along a straight road with lots of rising and falling at a steady pace around the same speed as for the hill climb and descent. In the high-speed area, vehicles had to travel at high speed both in a straight line and around curves with a large turning radius and no rising or falling.

New hill descent and climb and urban and suburban courses were created at Takasu Proving Ground. Because changes in elevation in existing areas were not what they were like in the United States, the hill climb and descent course was newly constructed on adjacent slopes.

In designing the suburban course, the road surface profile of the course in the United States was measured so the same level of driving comfort could be faithfully recreated. To reproduce the same ±1mm amplitude with one-meter road surface wavelength as in the United States, a new engineering technique was used in construction to recreate a road surface amplitude that produced vibrations in the 10 to 20 hertz frequency range, as necessary for evaluating driving comfort.

Condensed into 16 kilometers—combining US Hill Climb and Descent and US Urban and Suburban Courses with part of the High-Speed Circuit—are all the elements from the approximate 35-kilometer route in the United States that contributed to the evaluation process. As a result, the required driving time was reduced to 15 minutes, down from around 60 minutes. This has accordingly allowed for greater development efficiencies.

US Hill Climb and Descent

US Urban Course

The Vehicle Dynamics Test Area is the course for doing a general evaluation of a vehicle’s basic running, turning, and stopping performance. Other facilities include the 150R Skid Pad and IT Course, and the Hill Climb Course for also testing performance at urban intersections and during hill climbs and descents.

150R Skid Pad / IT Course

Hill Climb Course (winter)

Winding Course

The Winding Course, completed in 1993, was the first course at the Takasu Proving Ground to start operating. It was built in imitation of the Nürburgring Nordschleife track in Germany, known as one of the world’s toughest courses. When testing the original NSX (1990) at Nürburgring as part of the development process, Honda realized how difficult it would be to develop world-class vehicles without a similarly tough course on hand in Japan. It was this consideration that became the driving force behind construction of the Winding Course.

The difference in elevation at the Nordschleife is around 300 meters and there is a wide variety of curves, from low- to medium-speed corners through to high-speed curves rounded at speeds over 200 kilometers per hour. Cornering force reaches as high as one G on high-speed curves, while changing undulations combine with curves of varying size to impose huge suspension inputs, exerting powerful distorting forces on the vehicle body.

Visibility ahead is also poor on most corners, which come one after the other. Unless the vehicle responds exactly how the driver wants, the driver feels uneasy and cannot drive with confidence. There are even places where cars jump while swinging around curves at high speed. It is considered a grueling course for both car and driver (both physically and mentally).

Takasu Proving Ground’s Winding Course condenses the essence of the Nordschleife into a 6,180-meter circuit. Curves come in all sizes, having radii ranging between nine and 160 meters. The change in elevation is 57.5 meters. With tough angulation, blind curves, and jumps, the conditions torment both vehicle and driver. Vehicles are refined through repeated runs over the tough course, honing performance as far as it will go. They take on a dynamic performance that makes drivers feel the vehicle is moving at their command.

Winding Course

Takasu Proving Ground thus plays several roles—as a stage for cold regions testing; as a site for multi-faceted performance evaluations and assessments of driving and riding comfort for models to be deployed across the globe; and as a place for refining the running performance of Honda vehicles to be sent out into the world.

TechnologyHonda’s R&D FacilitiesTakasu Proving Ground: The Road Refines the Product