Honda’s R&D Facilities Chapter 2

Tochigi Proving Ground: The Road Decides the Product

Honda’s R&D Facilities Chapter 2

What Is a Proving Ground?

A proving ground is a testing facility where vehicles under development are put through extensive tests to fine-tune the technologies and the vehicles themselves prior to mass production. The actual vehicles are driven within faithfully recreated real-world environments and tested under harsh conditions to check basic running, turning and stopping performance. Results obtained through verification of the vehicle in actual use are fed back into the planning and development process.

When testing on public roads, variable surfaces and other road conditions make it difficult to obtain accurate data. It also requires a lot of effort to travel to locations to check performance under the envisaged conditions. Proving grounds have a variety of road environments on site, allowing repeated testing in meticulously controlled, highly realistic conditions. This enhances the efficiency of research and development, enabling quicker deployment of better technologies and products to customers.

Honda opened Japan’s first high-speed test course, the Arakawa test course, in 1958. The Tochigi Proving Ground opened in Tochigi Prefecture’s Haga district in 1979 to meet the expanding test requirements. The site has a total area of 1.41 square kilometers. It is where Honda verifies the durability and reliability of both components of vehicles and vehicles in their entirety, and tests vehicle quietness—for example, vibrations and noise—and dynamic performance, while also undertaking differentiation of grades and specifications and ensuring conformity with each target market.

Tochigi Proving Ground

Tochigi Proving Ground is perfectly tailored to Honda as it is where we carry out development testing of not only four-wheeled vehicles, but also motorcycles and power products, such as lawn mowers and tillers. For that reason, there are many types of course. They include an oval course, special surface course, vehicle dynamics test area, skid pad, hill climb and descent, a water pool, low- and medium-friction courses, a gravel road, winding and straight courses, motocross and supercross courses, a buggy course, and a power products test area. There are more than 40 different courses with a combined length of 74 kilometers.

Tochigi Proving Ground (2019 photo)

The four-kilometer Oval Course is basically split into four lanes—a special surface lane on the inside, moving out to low-, medium-, and high-speed lanes. Each corner of the high-speed lane has a maximum bank angle of 45 degrees, enabling test runs at up to 200 kilometers per hour. This is where we check a vehicle’s straight-line stability at high speeds, behavior during lane changing and braking, and quietness.

Oval Course

Oval Course bank

A crosswind blower on the Oval Course can blow typhoon-strength winds of up to 30 meters per second, making it possible to test the impact of crosswinds while driving, such as winds suddenly encountered on exiting a tunnel. Within the special surface lane inside the Oval Course, various road surfaces from all over the world are recreated for testing of noise reduction and driving comfort. There are 10 types of surface, including rough concrete, cobblestone (often found in Europe), and Belgian block roads. For the Belgian block road, stones were procured from Belgium and laid one at a time by hand. Other road surfaces include concrete pavement, which is often seen in the United States, and an undulating road surface.

Special Surface Course

Special Surface Course (Belgian block road)

The Vehicle Dynamics Test Area is 1,200 meters long and 52 meters wide. It is used mainly for verifying brake characteristics. The Skid Pad, with a steady-state circle measuring 200 meters across, is used to test the effects on chassis, suspension, tires, and other parts when driving at a constant speed. This is also where international certification testing and verification of tipping limits and brake performance are carried out.

There are four different hill climb and descent roads for testing performance on hills. There is even a Low μ (mu) Hill Climb and Descent with a slippery surface. The Water Pool recreates conditions of surface flooding. It allows immersion tests with flexibly adjusted depths.

Low μ Hill Climb and Descent

Water Pool

The Low μ (mu) Course is paved with a special type of tile and recreates slippery road surfaces, such as roads covered with snow or ice, by spraying water onto the surface. This course is used primarily for testing features like Vehicle Stability Assist (VSA) and all-wheel drive performance in conditions where wheels are likely to lock up or slip.

The 1.7-kilometer Gravel Road is for testing endurance and comfort on loose stones or gravel. The Winding Course has a highly technical layout like Suzuka Circuit (Suzuka, Mie Prefecture), with a combination of consecutive curves of varying radius. It is used to check vehicles’ handling stability and turning performance. There are also tight corners, with a small radius, and a winding course for motorcycles.

Gravel Road

Winding Course

A wide range of drivability testing takes place on the 1.6-kilometer Straight Course. The Motocross and Supercross Courses are based on courses used for world and national championships. The Power Products Test Area has sections planted with a variety of grasses from around the world and sections recreating a wide range of soils. It is where lawn mowers, tractors and tillers are tested.

Motocross and Supercross Courses

Power Products Test Area

Tochigi Proving Ground Sakura

Honda opened Tochigi Proving Ground Sakura (Sakura, Tochigi Prefecture) in 2016. This was to enable efficient development of advanced safety technologies, which have become increasingly important.

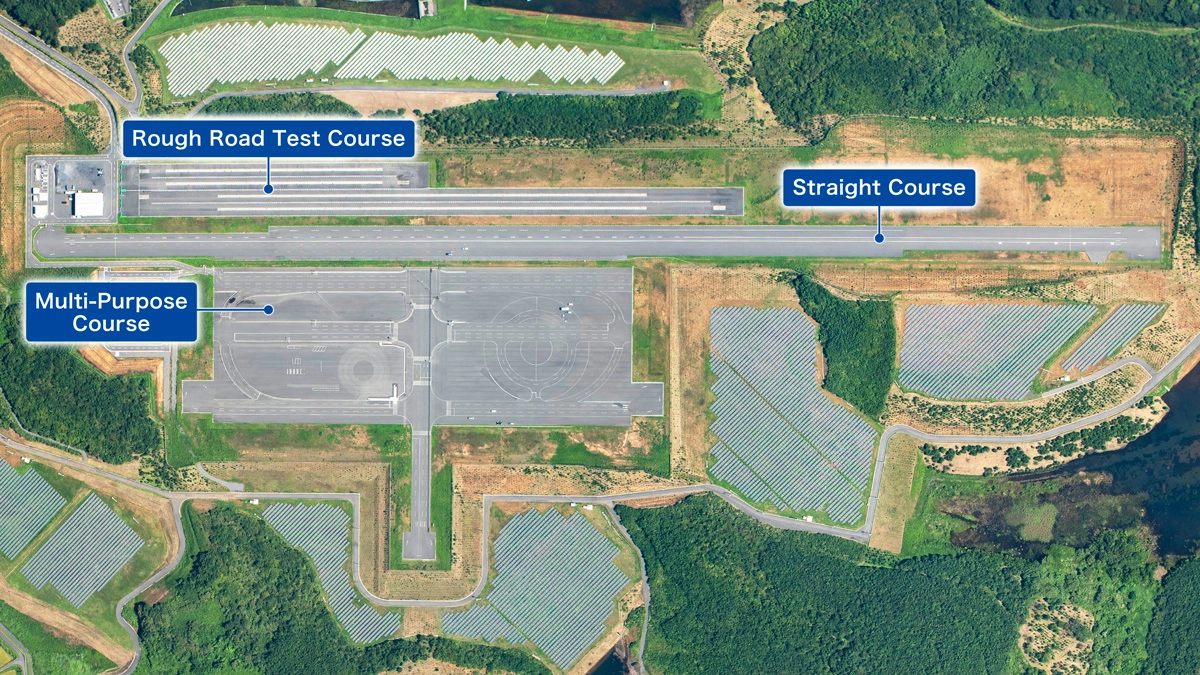

Test courses consist of a straight course, multi-purpose course (simulated urban area course), and rough road test course. The Straight Course, approximately one kilometer long, is primarily used to test avoidance support features, such as the Collision Mitigation Braking System (CMBS) and the Road Departure Mitigation System, which form part of the Honda SENSING driving safety support system.

On the Simulated Urban Area Course, which recreates signalized intersections and roundabouts (circular intersections), we carry out tests of Traffic Jam Assist and parking assist functions (including automated parking). We can also carry out tests addressing side-impact collisions with cross traffic at intersections and vehicle-to-vehicle communication verification tests.

The Multi-Purpose Course was established for the purpose of carrying out performance verification of automated driving on ordinary roads, automated driving on expressways, and advanced driver assistance. Performance verification of automated driving on ordinary roads needs to take into account regional traits and existing test courses were deemed unable to do this. The Sakura proving ground was established to take over these activities from the Tochigi Proving Ground.

Tochigi Proving Ground Sakura (2019 photo)

Verification testing of automated driving needs to be able to support road conditions, such as roads of varying curvature and roundabouts, and traffic regulations, such as obeying traffic signals when passing through intersections. Overseas intersections and traffic signals also need to be supported. The Straight Course has road markings and boundaries that faithfully recreate overseas environments and we have in place environments for verifying automated driving that reflect both conditions and regulations both at home and abroad, even on the Simulated Urban Area Course.

Multi-Purpose Course (Japanese intersection and traffic signals)

Multi-Purpose Course (Overseas intersection and traffic signals)

Honda has declared it aims to achieve zero fatalities in traffic collisions involving Honda automobiles and motorcycles worldwide by 2050.* The potential deployment of automated driving technology is one aspect of this. Tochigi Proving Ground Sakura is the facility that will help to expand deployment of driving safety support technology and thereby bring about a world without road fatalities and unleash the joys of freedom of movement.

* Traffic accidents involving Honda motorcycles and automobiles: Traffic accidents involving riders or drivers of Honda motorcycles or automobiles, as well as pedestrians and cyclists (i.e., all traffic participants except intentional rule violators and persons who lack the capacity to take responsibility)

TechnologyHonda’s R&D FacilitiesTochigi Proving Ground: The Road Decides the Product