Tech Views — Vol.8 CRF1000L Africa Twin

Development Story (3/5)

Not Only Touring Performance,

But Also Off-Road Capabilities.

Engine types must be selected depending on the attributes of the machines in which they'll be mounted, as well as on their intended power characteristics. It is also important to bear in mind the size and weight of the engine relative to the space available in the chassis design, not to mention the product features.

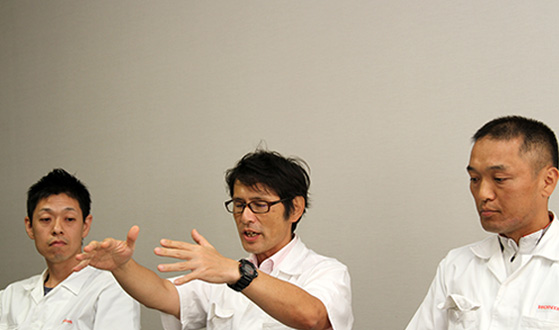

Yamakura — "What we wanted above all else was a lightweight machine. Besides being slim and compact, models like this require a responsive feeling of front tire contact with the ground, and so it's best to locate the front tire as close as possible to the rider, even if by only a millimeter or two. Moreover, since I wanted to simplify the design wherever possible and make the external design neat, I selected a parallel-twin engine design that is short in longitudinal length."

Displacement was originally set at 1,000cc in view of the fact that this provides the best balance between needed output and lightweight and compact proportions. Strong output as well as physical size and weight that can be easily handled by anybody were also conditions required of the new Africa Twin.

Yamakura — "As an engine designer, I know it's possible to attain power outputs of upwards of 200PS from a 1,000cc engine, however this would mean it would no longer be the Africa Twin we envisioned. So I decided that a 1,000cc parallel two cylinder configuration would offer the best balance. When taking overall controllability into consideration, I came to the conclusion that 70kW in output would provide the desired strong low-end torque and reduce power at higher revs."

The earlier Africa Twin had employed a V-twin engine that at the time was regarded as ideal in terms of size, weight and power feel. However, current state-of-the-art technologies make possible more lightweight and compact construction, and a feeling of power that still provides a sense of being highly controllable, even with a 1,000cc parallel twin engine.

Iida — "V-twin engines can be quite difficult to fit into a motorcycle, particularly in regards to the positioning of the rear cylinder. If the rear cylinder is located there, it impairs the rider's foot contact with the ground. I laid out the arrangement of the axes dozens of times before finally settling on a design plan."

However, other problems arose. As the development phase approached the actual process of giving form to the engine, at the stage where specifications were nearly finalized and the the prototype was about to be made, a request was received from the design team for a modification.

Komatsu — "I didn't intend to interfere in the designs of the chassis and engine, but there was just one area where things didn't match up as I'd expected. Although it involved the shape of the engine, the first silhouette never did produce a sense of neatness and integration with the complete package. Even though it was only one small area that actually required modification, modifying a section that had already been finalized required a complete redesign of virtually everything all over again. I felt bad about making such a request, but eventually persuaded the rest of the team by reminding them that we couldn't compromise our dreams for the new Africa Twin."

In line with the Africa Twin's desired attributes, engine characteristics needed to be made compatible with off-road performance, not to mention the desired touring performance, and both brought into a high degree of balance. Good touring performance requires a comfortable feeling of power that can be easily accessed over even long rides, while good off-road performance should provide both excellent traction over unpaved roads and a noticeable sensation of the engine's power pulses.

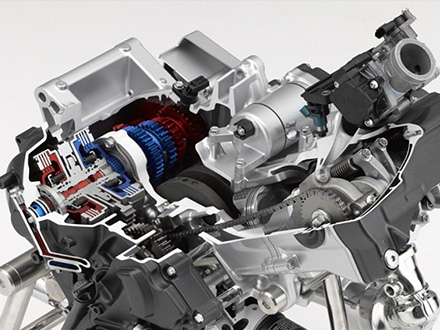

Iida — "So, assuming the original Africa Twin to be a rival of sorts, I thought that the new version should have more tractive performance, a torqueier delivery from lower in its rev range, and a pulsating feel as revs increase. As a result of extensive research, what we settled on was a 270 degree offset crankshaft. This irregular combustion interval provides the tractive performance we were looking for, as well as a pulsating feel while also effectively cancelling out secondary vibration. I figured that we could achieve the desired results by merely installing a balancer to reduce primary vibration."

The structure of the chassis in which this new-generation engine would be installed was determined in a fairly orthodox manner based on the policy of maintaining the Africa Twin's highly appraised strong points without showing off its originality. One reason was that if even the chassis is also made new because the engine was replaced with the latest generation available, it would be virtually impossible to ensure the reliability and durability required of the adventure touring model.

Yamakura — "Using the original Africa Twin's chassis and body design as a reference, we tried to keep its basic concept, but we also needed to retain the Africa Twin's good handling and operating ease, as well as its other highly regarded assets. Our goal was to create a form that was equal to its predecessor in size, yet offering one-and-a-half times the output combined with a lighter vehicle weight, even if only by a single gram, and which gives the impression of being imposing yet even-tempered when ridden. I felt that this size would be good for expressing the Africa Twin's ruggedness, dependability and manageable nature."

Development had reached the point where the prototype was just on the verge of its first actual road test. The number of test members had also increased, allowing the project to begin to proceed to the commercial production planning stage, where the new model could be run on a larger scale.

- Top

- History

- A New Era

- Technical Points

- Development Story