Endeavoring to Expand the Scope of Human Activities to Outer Space The Circulative Renewable Energy System

Nearly fifty years have passed since humans landed on the Moon for the first time, an event that excited the whole world. Humans are again attempting to land on the Moon in 2024. This time, there is a plan to build a base for long-term continuous activities on the Moon. Honda is engaged in technological development of a key system responsible for supplying breathable oxygen, hydrogen for fuel and electricity for an array of applications. Honda is working towards realizing the dream of adapting the Moon's biosphere to be suitable for humans by using sunlight and water on the Earth's natural satellite.

Construction of Infrastructure for Long-term Habitation and Activities in Outer Space

When humans landed on the Moon for the first time in 1969, astronauts stayed there for less than a day. The United States wants to land on the Moon again by 2024, and in order to do so, it established the Artemis program designed to bring humans back to the Moon as well as build a base on the Moon's surface.

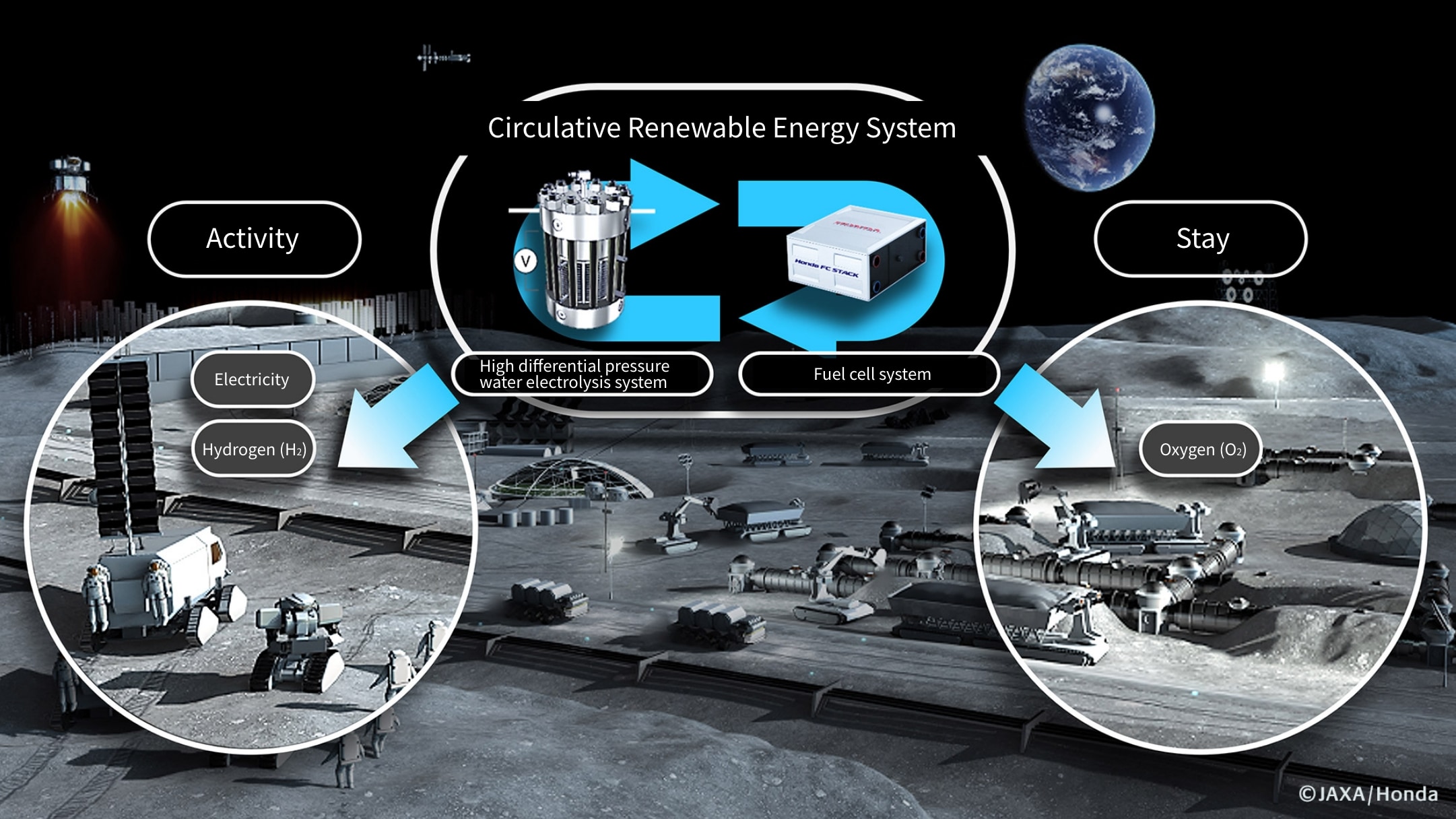

In order to stay for extended periods of time on the Moon, humanity must create the necessary infrastructure. Honda is conducting joint research with the Japan Aerospace Exploration Agency (JAXA), an international partner member of the Artemis program, towards the creation of the circulative renewable energy system that uses sunlight and water, expected to be on the Moon, to produce and circulate oxygen for breathing as well as electric and hydrogen energy.

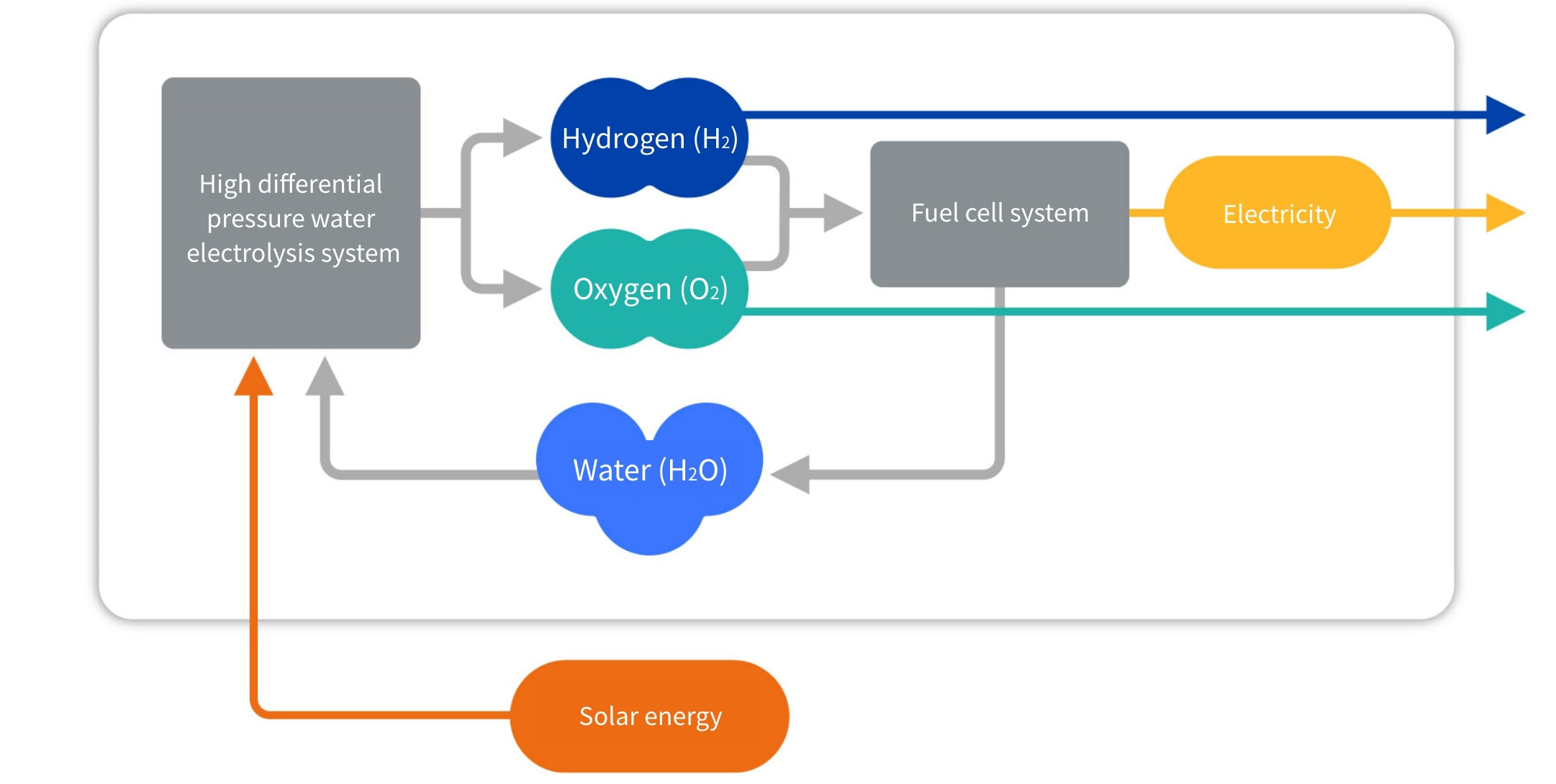

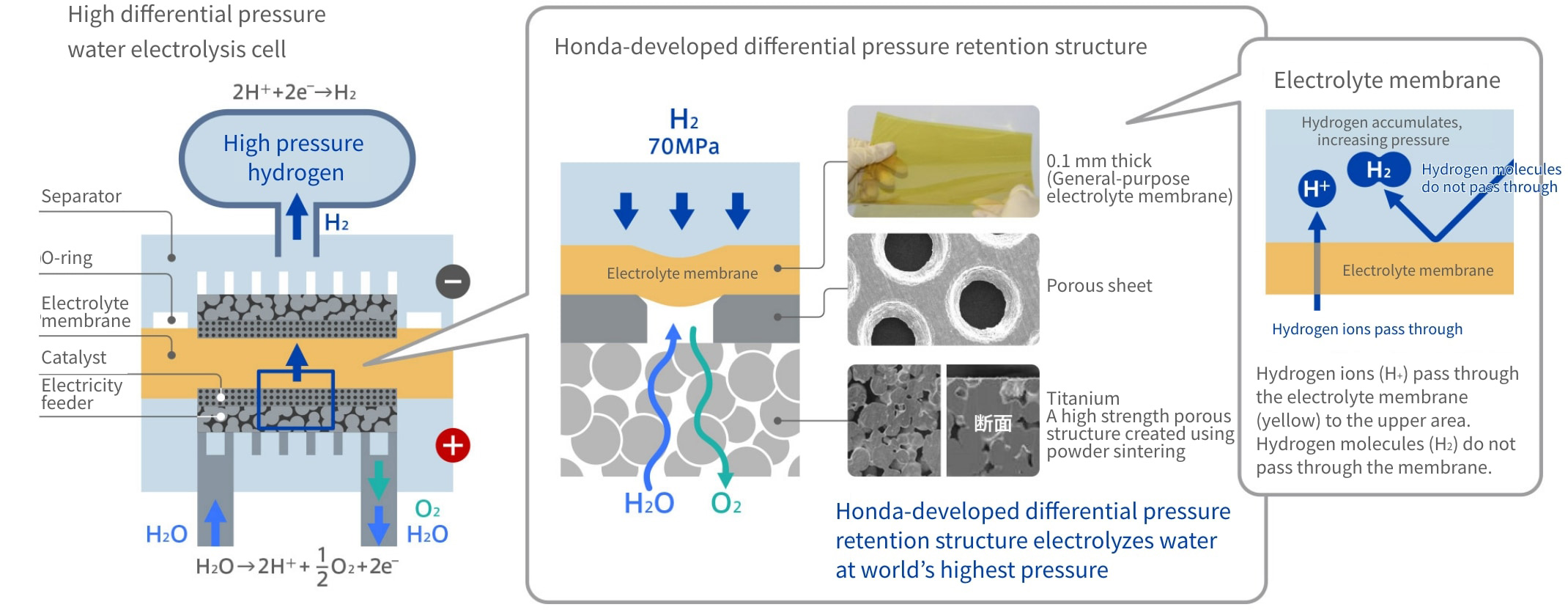

The circulative renewable energy system incorporates a high differential pressure water electrolysis system. It electrolyzes water to produce high pressure hydrogen and oxygen. Humans can breathe some of the oxygen while the remainder can be stored in fuel cells for electricity generation. The fuel cells discharge water that is returned to the high differential pressure water electrolysis system, completing the energy cycle.

Circulative Renewable Energy System

Achieving Top-Class High Differential Pressure Water Electrolysis Technology

Hydrogen can be produced from various resources. It attracts attention as a next-generation source of energy that does not emit carbon dioxide. Honda focuses on this source of energy in its development of the Power Creator which electrolyzes water to produce hydrogen, which has been adapted for use with fuel cell vehicles and hydrogen stations that supply hydrogen to households. Honda developed the high differential pressure water electrolysis system that is the core technology for the Power Creator.

A hydrogen molecule consists of two hydrogen atoms. Hydrogen gas is so low density that it quickly escapes even when stored at low pressure. To retain a sufficient amount of hydrogen for use, it is necessary to store a large number of hydrogen molecules at high pressure in a tank. While mechanical compressors are generally used, Honda has independently developed a differential pressure retention design capable of storing hydrogen at high pressures without using a compressor. This high differential pressure water electrolysis achieved one of the greatest pressure differences in the world.

How Honda Technologies Help in Outer Space

The high differential pressure water electrolysis system was praised by people inside and out of Honda as a very valuable technology. When development staff sought new applications, they thought it might be useful in space or on the Moon. Honda researchers at that time visited JAXA to explain the technology.

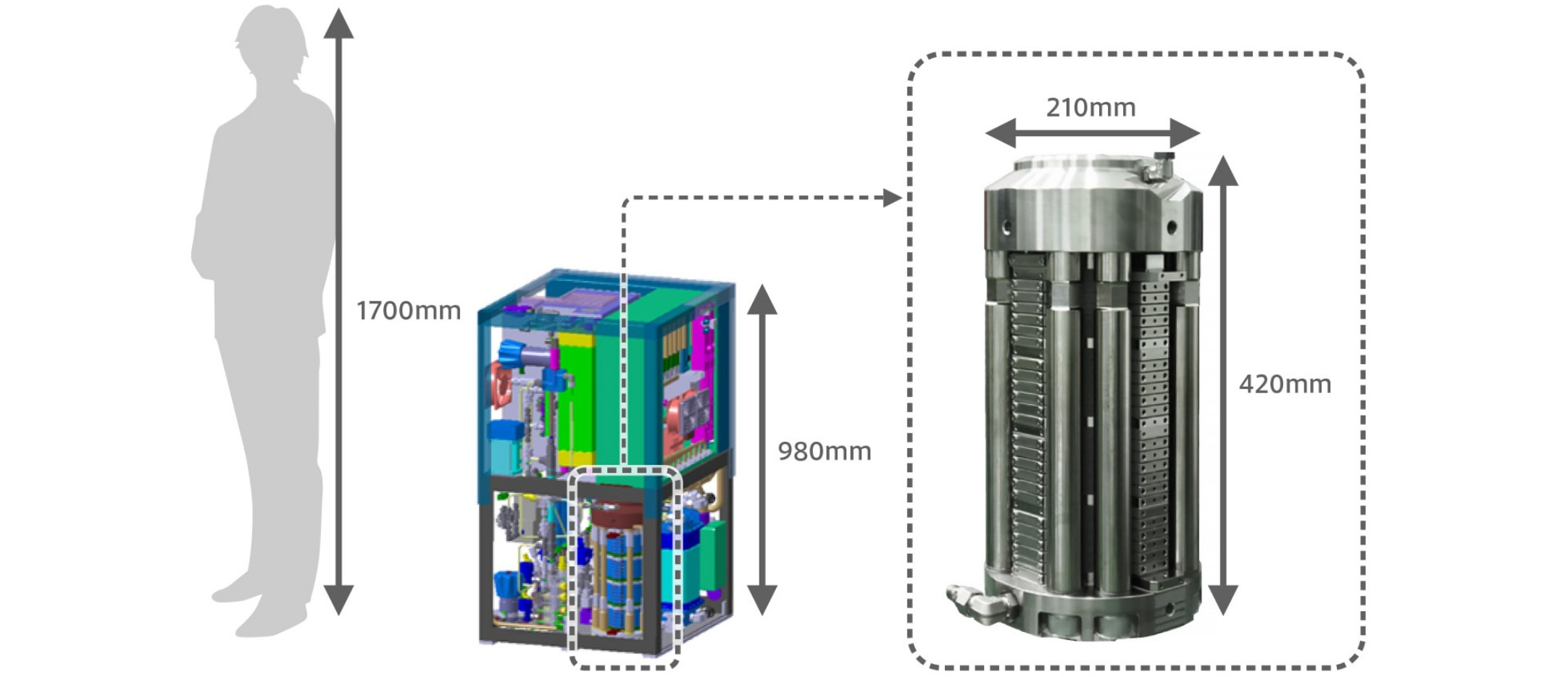

The cost of transporting an object to space is generally said to cost 100 million yen per kilogram. Equipment destined for outer space therefore needs to be lightweight and small. JAXA was impressed by Honda's high differential pressure water electrolysis system for storing hydrogen at pressures as high as 70 MPa, which is about 700 times Earth's atmospheric pressure. They were also impressed by its light weight and compact size, and by the low frequency of required maintenance because it has no mechanical compressor. This had led to Honda’s recent research.

Size of the high differential pressure water electrolysis stack

Example of the stack incorporated into a next-generation solar hydrogen station for home use used in the field trial in Los Angels

Creating High Pressure Without a Compressor

The principle behind differential pressure water electrolysis is well known. Hydrogen ions generated by electrolysis are concentrated at high pressures through an electrolyte membrane. This membrane is permeable to ions, allowing hydrogen ions (H+) generated by electrolyzing water to pass through to the other side of the electrolyte membrane, where pairs of hydrogen atoms join to form hydrogen molecules (H2). Unable to pass back through the membrane, hydrogen molecules continue to accumulate and pressure increases.

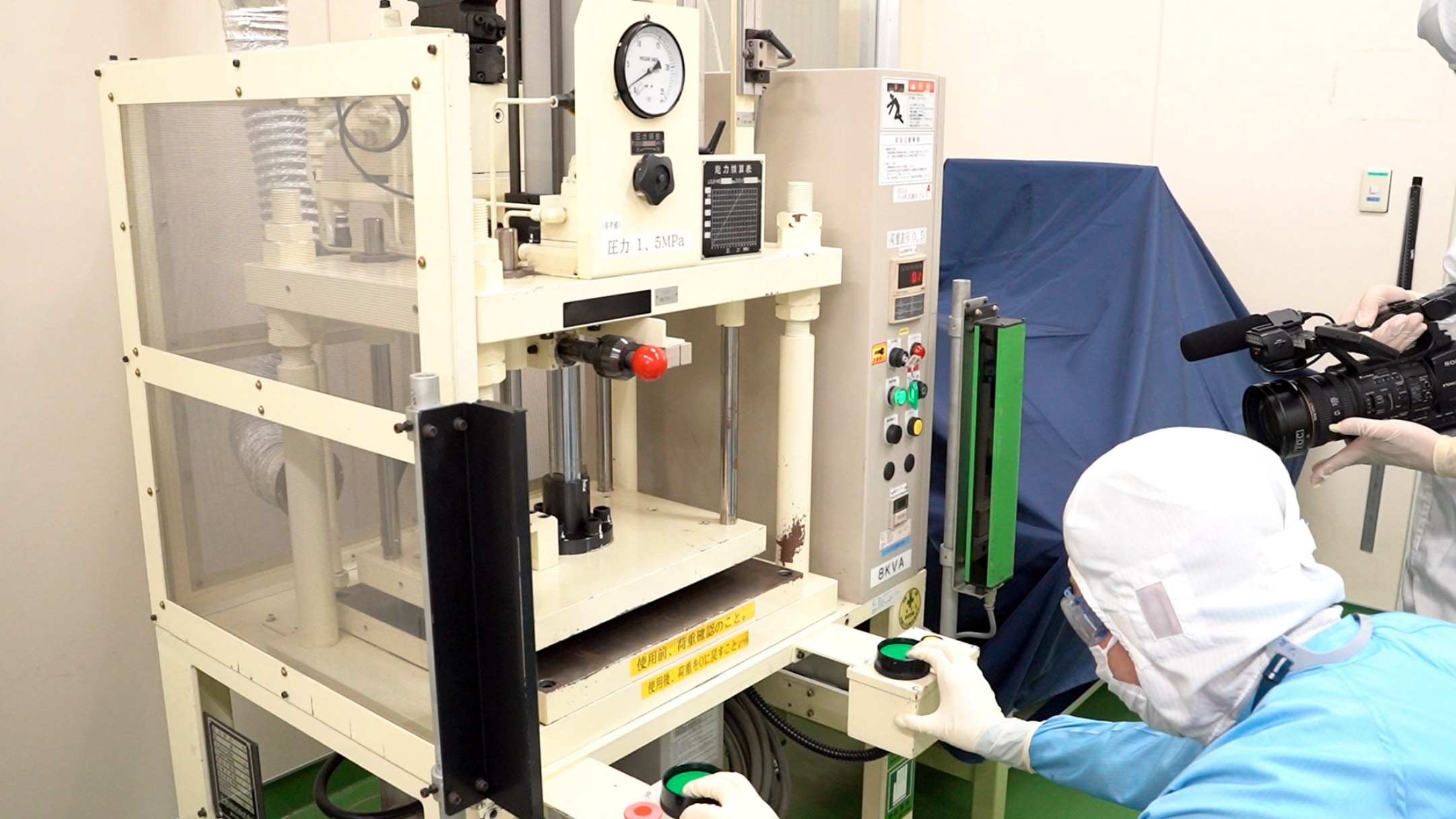

The electrolyte membrane has a thickness of merely 0.1 mm or so. 70 MPa is about 700 times the Earth's atmospheric pressure, so high that it applies a force of 700 kg per square centimeter, which leads to tearing of the membrane. Honda has developed a support structure that evens the force applied to the electrolyte membrane and a porous material that is able to withstand the high pressure. This enabled Honda to maintain that pressure without the membrane tearing. Using Honda-developed models to conduct simulations, materials were repeatedly prototyped and tested, resulting in the creation of an appropriate material for the project.

How Technologies Developed in Outer Space Can be Applied Back on Earth

The environment on the Moon is harsh. The temperature varies significantly between 110 °C in the day and -170 °C at night. Gravity is one-sixth of Earth’s. Without air, the Moon’s surface is exposed to huge amounts of radiation. The extreme conditions for development in space mean that humans must meet tough goals to fulfill the difficult needs that technologies are asked to achieve, beyond the harsh environmental factors. It is important to improve fuel efficiency and efficiency as a whole on the Earth as well. However, on the Moon, the slightest decline in efficiency can directly lead to an increase in the number of solar panels and other materials that need to be transported from Earth, meaning a cost increase of 100 million yen per kilogram. Honda therefore must work to maximize efficiency, the lowest weight and the smallest size possible. Honda will do this in the hope that the advanced technologies obtained as a result of the pursuit of efficiency to meet challenging requirements will be actively utilized on the Earth.

Technologies required on the Moon and in other outer space environments where extreme sustainability is necessary will be an indispensable part of sustainability on Earth as well. Honda is convinced that it is vital to develop circulative renewable energy systems as they are a technology that will lead to carbon neutrality.

Main components of the high differential pressure water electrolysis system

A system incorporated into solar hydrogen station that was used in the field trial in japan

Realizing the Dream of Sending Products to the Moon with a Honda Logo

Honda has been providing many different products and technologies for use on land, in the sea and in the air. Now, Honda has chosen outer space to be the next field to cultivate, believing outer space is an area for new dreams and endeavors where its core technologies can be used to enrich people's lives.

Honda has a history of taking on new challenges, including its entries in the Isle of Man TT, Formula One racing, the environmentally friendly Compound Vortex Controlled Combustion (CVCC) engine and the HondaJet small business jet. Honda’s efforts to develop the circulative renewable energy system will be part of its history of endeavors. Honda will aspire to send products with the Honda logo to the Moon and to help realize the dream of adapting the Moon's biosphere to be suitable for humans.

INDEX

TechnologyCirculative Renewable Energy System