Motorcycles Technology

CBR1000RR-R Engineers Talk

Receiving power and moving a vehicle

Sekiya:

What kind of frame can receive that enormous power?

Ishikawa:

In a nutshell, a supple frame.

When it is flabby, a motorcycle cannot go straight. When it is too stiff, the rider cannot feel responses to go daringly.

Once constructing a frame thoroughly to serve as a framework, we developed a structure to ensure the optimum suppleness through trial and error.

Koyano:

Because of this powerfulness, I do not say that everyone can handle this motorcycle.

But I have wanted to create an “easy-to-ride” machine.

That is why we decided on these dimensions to be large to some extent. Our aim was to create a vehicle that could receive “information” transmitted from the road.

Sekiya:

Mr. Ito, you tested the frame with a previous engine mounted. Was the impression good from the start?

Ito:

The front tire grip feeling was good from the beginning. I was initially concerned that the traction feel might be less.

Sekiya:

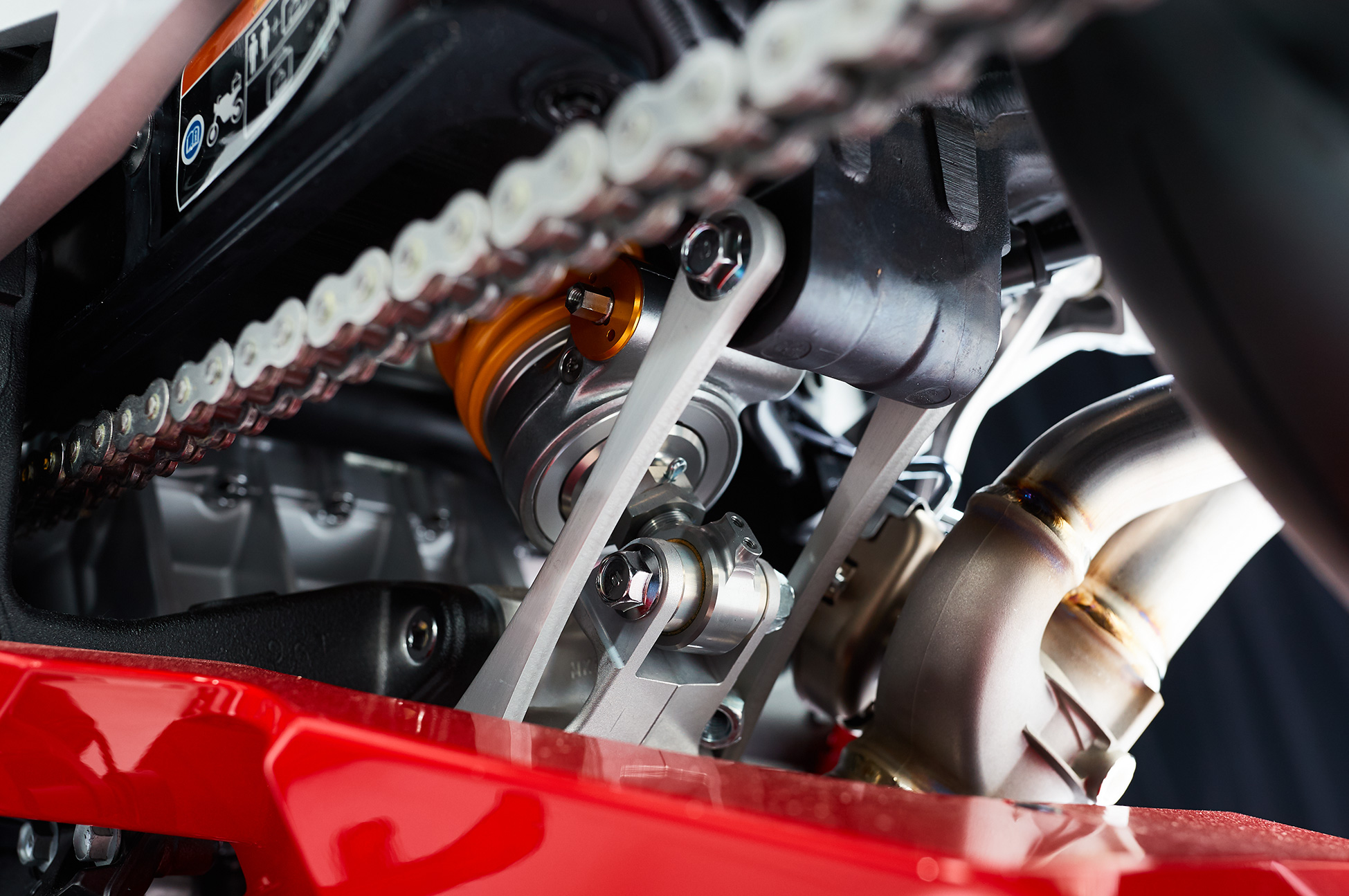

Because the model comes in the new structure with the upper mount for the rear shock located on the engine.

Ito:

But in reality, as the rear shock pushes the location on the engine during acceleration, it has become easier to grasp behaviors.

The impression of the previous unit Pro-Link was rather to move the swing arm only. This new method has allowed to use the unprecedented high power with ease.

Sekiya:

Mr. Ishikawa, you have been involved in the frame development for a long time. How do you feel about the new frame?

Ishikawa:

I can say with confidence that we have devoted in full scale the know-how on frame development Honda has fostered.

Because we kept working on it until the very final moment before the mass production start-up, now I feel, “Thank God, it’s over.” (laughs)

Koji Koyano (Steering Stability Research)

Hired in 1981.

Involved in developments of the NSR250R, BROS, VFR800X, CB series, X-ADV, and CBR1000RR.

Belonged to HbRC from 1992-2009 to conduct vehicle tests of works motorcycles such as the NSR and RC212V.

Participated in the All Japan Road Race Championship as a member of the internal team (Blue Helmets MSC) in his 20s.

Competed in Suzuka 8 Hours twice.

Sekiya's Eye

The aim of the new frame is to allow flexible handling and grasp behavior more easily while stabilizing a vehicle running at high speed. For this reason, it tends to curb lateral rigidity more than before.

For example, during a banked turn at a maximum lean angle, the direction of load applied vertically from the road to the tire is significantly different from that of the load along the vehicle’s vertical axis (which is equivalent to the bank angle) for the rear shock to activate.

As a result, the rear suspension alone cannot handle the shock. The mainstream approach for today’s MotoGP machines is the frame itself bowing in the lateral direction to absorb load applied from tires.

Additionally, optimization of response speed of the vehicle and information given to the rider has probably improved turning ability as a result.

Universally accepted 218PS

Sekiya:

Mr. Ito, what did you think when you rode the machine in the state with the new engine and frame assembled?

Ito:

Of course, in this initial stage there were many things to improve. But the machine was made such that I could immediately visualize what should be done and what the intentions were.

After each test, we ground here and there, modified tightening torques, and made really minute changes until the end of the development.

Sekiya:

It must have been a chance to show off your skills as a test rider. What was Mr. Ito’s feedback like? “Well done” or “I could do better” or anything? (laughs)

Hosokawa:

Although we repeated test track tests more often than is believable in the past mass production vehicle development, to try any and all kinds of specifications, he ran the motorcycle almost the same way each time and gave us precise feedback on changed designs. He really helped us.

Sekiya:

In regard to the electronic control, just providing it is not enough. What is important about it is whether it makes riding easier for the rider.

Okoshi:

Since the direction of the concept has been changed from the previous generation’s “fun ride on the public road” to “fastest on the race track”, expectations to the electronic controls have been upgraded.

However, the concept of “Total Control” handed down to the CBR-RR is unchanged. “Universal acceptance” should never be forgotten.

Ito:

Not only to the traction control and wheelie control, but we also fussed over considerably tuning the throttle-by-wire opening setting and responsiveness. We focused on how to make this 218P user-friendly for general riders.

The motorcycle would not let out power all of a sudden. The throttle connects smoothly from the “initial opening” to the full.

The feel will be completely different even with the same power.

Fuyuki Hosokawa (Deputy Large Project Leader)

Started working for Honda in 2000.

Ran around in Hokkaido and on race tracks during his student years.

Joined Honda with an aspiration to develop the CBR.

His responsibilities include concept study, test arrangements from the 2012 model CBR1000RR to the new model as Deputy Large Project Leader after dynamic force research.

Owns a CB1300 SUPER BOL D’OR.

Satoru Okoshi (Control Systems Design)

Hired in 2004.

Engaged in control system design for mainly large FUN models such as CBR1000RR (2008), NC700 series (2012), RC213V-S (2015) and CBR1000RR (2017), after the 2006 model CB600F Hornet.

Sekiya:

Suspension is also electronically controlled, isn’t it?

Ito:

If a rider were an active and tough professional racer, it would not be a problem without electronic control. But if not, mastering it will definitely help for running faster.

The development team worked jointly with Ohlins to develop it. My impression is that the suspension behaves “reasonably” just by putting it in auto mode.

Sekiya:

Convincing control even to a racer.

Ito:

Another thing that astonished me regarding the suspension was that steering feel was almost no different between the Ohlins suspension for the SP model and Showa for the standard model.

I can say this proves that the vehicle is very well done.

Sekiya's Eye

The unit Pro-Link has been built onto the CBR series since its development for the RC211V in 2002, for the reason that its structure with its shock unit separated from the vehicle keeps the load generated at the rear suspension from affecting the vehicle, especially in the high speed range.

This time, it was to streamline the vehicle structure that the upper mount of the rear shock was changed to the engine mount to use the universal Pro-Link.

Thanks to this layout, the cross member connecting the main frame from right to left was successfully eliminated, prompting rigidity balance to improve and at the same time weight to be reduced.

The advance of frame analysis, forming technologies, and machining technologies underlies adoption of this style.