The HR21 Lawn Mower / 1978

Motorsports History

Lawn Mower Development: Global Expansion for Honda Power Products

Following the development of Honda's 1953 Type H engine, the company steadily expanded its line of general-purpose engines by launching the Type T and VN models. The field of complete products saw considerable activity also, with market expansion significantly aided by the F150 tiller (released in 1959) and E40 generator (1964), along with several pumps and outboard marine engines.

The high-quality, high-performance HR21 walk-behind lawn mower, developed in order to expand Honda’s power product market worldwide.

Honda began the full-scale exportation of tiller products to France in 1963 as part of an aggressive strategy to cultivate the market for power products overseas. Yet, despite the recognition of their high quality and superior durability, Honda power products lacked the cost advantage they needed to compete in a price-driven market. As a result, Honda could not yet expand its power product operations globally.

The ME engine (G150/200) introduced in 1977 represented Honda's effort to develop a new family of powerplants that could maintain the high quality associated with Honda products yet be affordable enough to compete in the global market. Named ME (Million Engine) as an expression of the company's high sales expectations, the product was given a challenging mission: to help sell one million units and build the foundation on which Honda could establish Power Products as a third major operation.

Worldwide annual sales of power products were around 20 million units during the 1970s, with the so-called "green" market (lawn mowers) accounting for 8.5 million units. Therefore, to any industry player lawn mowers represented a very appealing and potentially profitable market.

Honda's power-products operations during that period were limited to sales of complete machines in Japan and France. Moreover, the company had few sales bases in the U.S. Therefore, to increase the sales of its power products from less than 300,000 units to over one million, Honda would have to establish a worldwide sales network covering these untapped regions. Accordingly, as the principal category with which to build this vast network, Honda chose the commandingly large market of lawn mowers.

The First Step: Know the Grass

It was the summer of 1975, and Takeo Ogano had recently completed a key phase of an R-research project in which he was developing a new technology for the ME engine. It was then that he was ordered to create a lawn mower. This was a baffling request to Ogano, since Honda - a manufacturer in a country with very little grass to mow - should wish to enter a market filled with dedicated, expert makers of lawn mowers. Despite his confusion, however, Ogano began working on the project. He decided to go back to the basics, that of course being research. His objective was to understand the lawn mower and define what Honda should look for in such a machine.

Ogano was convinced that he would invariably hit a wall if he focused exclusively on the engineering of hardware. He knew he would not come up with a workable product concept without answers to several questions. These he would obtain by understanding the key elements required of a lawn mower.

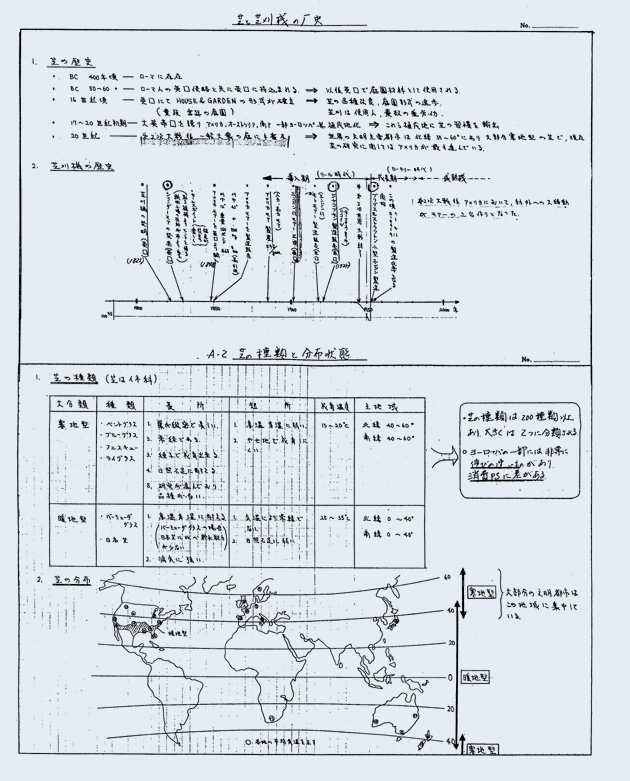

Ogano began by studying the grass itself, learning about its histories and geographical distributions around the world. Moreover, he studied the engineering aspects of lawn mowers based on models and catalogues from other companies. Still, he was unable to identify the quality he sought; the quality that would connect the machine and the user and thus create product appeal. It was then that Ogano was instructed by Honda R&D Director Kiichi Momota to visit the markets, where he could experience local environments and understand the tool's real-world applications. He immediately left for the U.S. and Europe, hoping to verify with his own eyes the things he could not see on paper. It was February 1976.

Samples of grass were brought back from various countries (The photographs depict samples taken in France.)

Pulling out Grass to Collect Samples around the World

Ogano toured most of the countries that represented a significant lawn mower market, including England, Germany, France, Switzerland, and the U.S., studying the local manufacturers and retailers as well as maintenance practices. He also visited local trade shows to collect information regarding existing models.

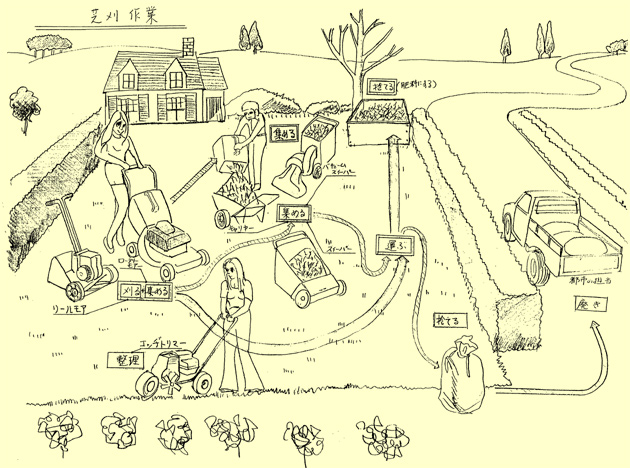

A drawing used to identify product requirements for a new lawn mower

At each location, Ogano studied the average number of hours the owners would use their machines, factoring that against the average lawn area, user profile and specific style of use. Moreover, he became absorbed in the study of plant characteristics, using samples from each particular region. In suburban Paris and Los Angeles, he pulled up grass in the gardens and cottages of customers introduced by local retailers - and sometimes even grass growing by the roadside. Through these efforts he was able to identify the requirements for Honda's new lawn mower, incorporating his data and broad new perspective.

Extensive study was implemented in order to learn about grass, including its history and worldwide geographical distributions.

Ogano immersed himself in research immediately upon his return from the worldwide study tour, building a prototype and conducting several performance tests. Ogano flew to Europe again in June 1977 to see whether his prototype machine would prove functional in the actual market, and to observe how it was received by local users. The series of local-adaptability verifications he conducted in various locations helped Ogano gain much of the knowledge he would need to complete the product.

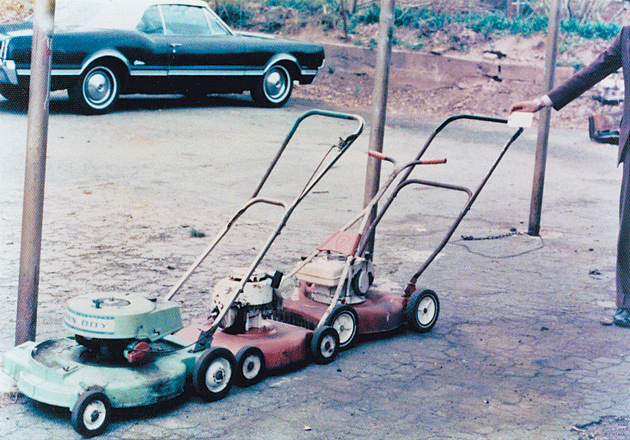

In Europe, other manufacturers' models were studied in order to gather critical information.

Honda Brand Expectations: A Renewal of Commitment

What most impressed Ogano during his travels through Europe and the U.S. was the strong recognition of the Honda brand. Whenever he and the local office staff entered a retail store, they would be welcomed by the store personnel, who were excited about having visitors from Honda. He was even introduced to lawn mower users by personnel at Honda motorcycle specialty stores, which had nothing to do with lawn mower sales.

These experiences left Ogano thoroughly convinced that he would never do anything to tarnish Honda's brilliant image among the consuming public; an image that was built through years of success in motorcycles and cars. He was determined to develop a lawn mower that could serve faithfully for ten, or even twenty years.

Unlike motorcycles and automobiles, which are sold at specialty stores and dealerships, lawn mowers are commonly sold in the U.S. and Europe in the gardening departments of general hardware stores, where products from several manufacturers are displayed. Many of these stores give priority to price, providing no after-sales service.

However, in order to give lawn mower users the level of satisfaction they would receive from a Honda motorcycle or automobile, it was desirable that the machines be sold at specialty stores with sufficient resources to provide quality after-sales service. Ogano therefore believed that Honda could maintain the high-quality image of its power products only by building and selling lawn mowers through a network of specialty stores capable of providing an equal measure of service. These would be the kinds of stores selling products that were not simply inexpensive but durable enough to withstand the rigors of extended use. From this idea, Ogano gradually came to a powerful realization.

The Makeshift Backyard: Encounters with Challenging Problems

Ogano, knowing that Honda had never before developed a lawn mower, began to feel pressure from within the company and outside. Among the influences were several flawed propositions and critical comments concerning the possible drawbacks. Therefore, Ogano had to work on his drawing in order to prove that each of these difficult problems had been resolved. For example, in response to a group of people who said the machine should have a seat so that the user could mow more comfortably, he attached an office chair to a prototype machine and demonstrated how its lack of stability would compromise safety. It was, after all, a lawn mower equipped with large blades.

Initial image drawing

As a solution to the limited capacity of the bag attachment, which would of course quickly fill with mowed grass, Ogano was instructed to add a function allowing the machine to store more grass by burning or drying the cut grass using heat from the muffler. To prove that idea wrong, he explained that grass is more than 90 percent water and presented the results of a calculation showing the amount of energy required simply to evaporate the water.

One particular opinion held that progress in biotechnology would soon create lawns having very limited growth, making lawn mowers obsolete. To counter the opinion, Ogano planted a lawn in a small space in his backyard in order to observe its growth. As the seasons progressed, the grass began to grow rapidly. As he mowed his lawn, he experienced a sense of satisfaction - a pleasantly refreshing feeling - that he was communing with nature. He was convinced the need for lawn mowers would never diminish as long as people continued to experience the joys they could not get from maintenance-free biolawns. Through the experience he not only found a convincing counter-argument but gained considerable confidence in the product he was developing.

A user testing the prototype in his own yard

"To address various opinions and demonstrate the validity of our product development," Ogano recalled, "I made many field trips and studied relevant subjects so that I could convince them with total confidence. These efforts eventually led to the final result."

It was nearly the end of 1975, some time after Ogano had begun studying the machine's design, that he was told by Mr. Honda, then the company president, that resin should be used for the housing. Ogano rejected such an idea. "In order to start a lawn mower," he explained, "the owner will often place his foot on the housing to prevent the machine from being lifted as he cranks the motor. That's why using resin for the housing would be dangerous. If it were dented due to pressure, it might contact the blades beneath. So, even though it would be cheaper, resin shouldn't be used for reasons of safety. I just can't accept that suggestion."

Improvements were added to the prototype through repeated local-adaptability verifications conducted in several countries. (The photograph shows a test conducted in France.)

Sixteen years later, in 1991, the U.S. corporation GE Plastics developed a resin having a level of strength equivalent to aluminum. With that, Honda became first in the lawn mower industry to employ resin in the manufacture of parts.

"When that happened," Ogano recalled, "I was impressed once again by the visionary thinking of Mr. Honda"

The basic structure's overall design thus having been completed, Ogano turned to the various functions his machine would need in order to outperform the competition. He was convinced that his new lawn mower would succeed in the market if it offered solutions to the problems that manufacturers in America and Europe had failed to address. Therefore, Ogano chose to design the lawnmower as a high-class machine having several key features:

[1] Quiet operation, allowing the user to mow without disturbing the neighbors

[2] Safety embodying the concept of active safety

[3] Easy operation so that even a woman could easily handle it

The process of trial and error was used to test various ideas and ensure that Ogano's goals would be met. For instance, a structure having the muffler tucked under the deck was examined in order to reduce engine noise. That idea was discarded, though, when it was found that trapped heat would kill the grass directly beneath the mower if the machine was allowed to run in a stationary position. Additionally, many hours were spent designing a mechanism to protect the user's legs against debris thrown up by the rotating blades. In order to guide the cut grass more smoothly into the bag, ways to improve the machine's vacuum efficiency were examined.

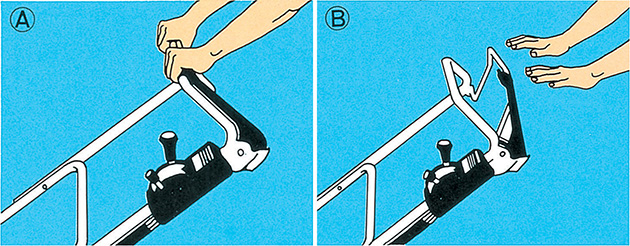

Safety was a primary concern, of course, so the machine was furnished with the world's first BBC (Blade Brake Clutch) mechanism. The system would automatically stop the blade rotation within three seconds if the user released his or her hands from the handlebar, meaning that the Honda's lawn mower could offer a degree of safety that no other manufacturer had even considered possible. In fact, the BBC mechanism played a role in the U.S. Government's enactment of a relevant CPSC (Consumer Product Safety Commission) regulatory safety standard. This technology gave Honda a dramatic lead over its competitors in the area of safety.

The BBC mechanism stops the cutting blades within three seconds of the user's release of hands from the handlebar. (The drawings represent the mechanism during development. Photographs courtesy of Takeo Ogano.)

Achieving the Target: Selling 300,000 Units

The HR21, Honda's first walk-behind lawn mower, was launched in August 1978 in overseas markets including the U.S. The high-quality lawn mower equipped with a vertical engine, which ensured quiet operation and significantly easier starting, received rave reviews for its outstanding performance, safety and durability. Sales were strong from the start, growing steadily to the point that in 1985, when sister models were introduced, Honda boasted total sales of 330,000 units from its line of lawn mowers.

Worldwide sales in excess of 300,000 units also led to the realization of Honda's ultimate goal. Assuming that 150,000 units were sold in the U.S. and Europe, respectively, these figures meant that networks of around 1,500 retail stores had been created on the two continents.

"In the end," Ogano said, "the creation of sales networks was a result of an effort by the sales side, which worked hard to achieve our strategy of building sales channels for power products. Then, once the HR21 was on its way, I became involved in the development of approximately thirty Power Products models, acting as LPL. These projects included carriers and snowblowers, allowing me to use expertise obtained through our lawn mower development. After all, that was a field in which I had to overcome many difficulties. Ultimately, though, the strong sales of the HR21, which used an ME engine, led to the birth of its successor, the ZE.

"I can definitely say that I was fortunate to be involved in so many development projects," Ogano concluded. "Working under these projects made me a much better development engineer in several ways. For example, I learned the importance of collecting and thoroughly studying relevant information during predevelopment, when we mull over our designs in order to create a workable product."