Motorcycles Technology

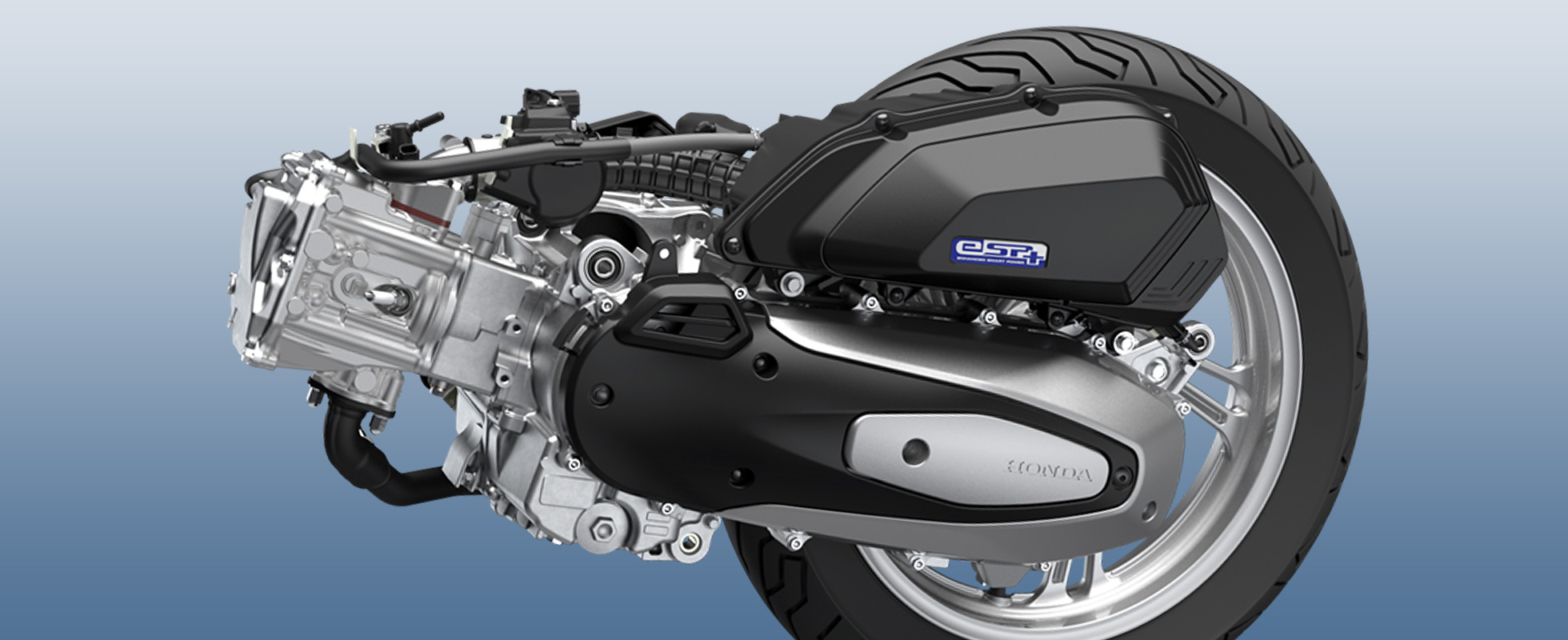

Overview of eSP+

The "eSP" engine for small scooters has been refined down to the smallest detail to achieve highly practical power output characteristics, excellent durability, quietness, high quality performance, and low fuel consumption. A 4-valve mechanism and new friction reduction technology have been applied to achieve even stronger power characteristics and excellent environmental performance.

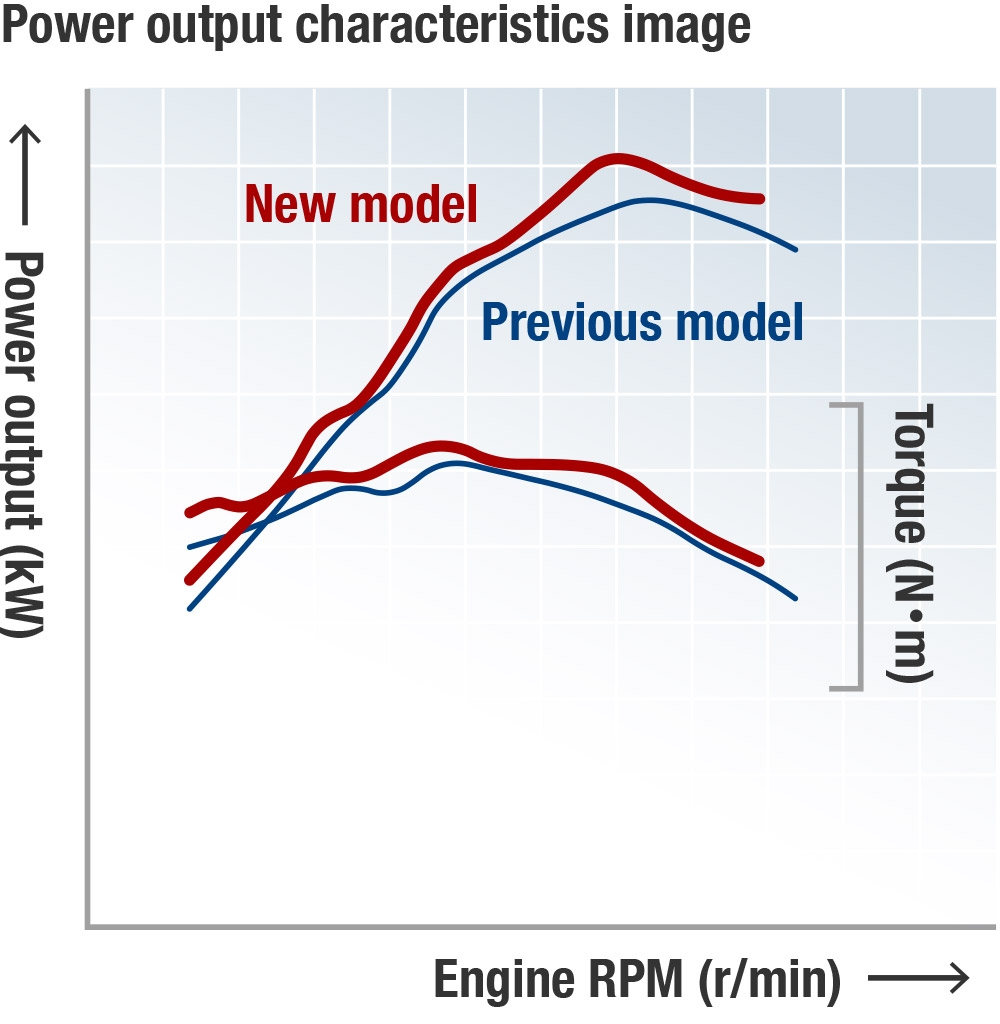

The eSP+ adopts a 4-valve mechanism, a new bore x stroke, a more rigid crankshaft, and a piston jet mechanism to increase power output. This allows the eSP+ to achieve category-leading performance.

4-valve mechanism

In contrast to the 2-valve mechanism of the regular "eSP", the "eSP+" adopts a 4-valve mechanism. By increasing the total valve area, the intake efficiency of the air mixture and the exhaust efficiency of the combustion gas are improved, resulting in higher power output.

Bore x stroke update

The bore has been enlarged and the stroke has been reduced. This contributes to enhanced power output by increasing the total valve area and reducing the sliding resistance due to the short stroke.

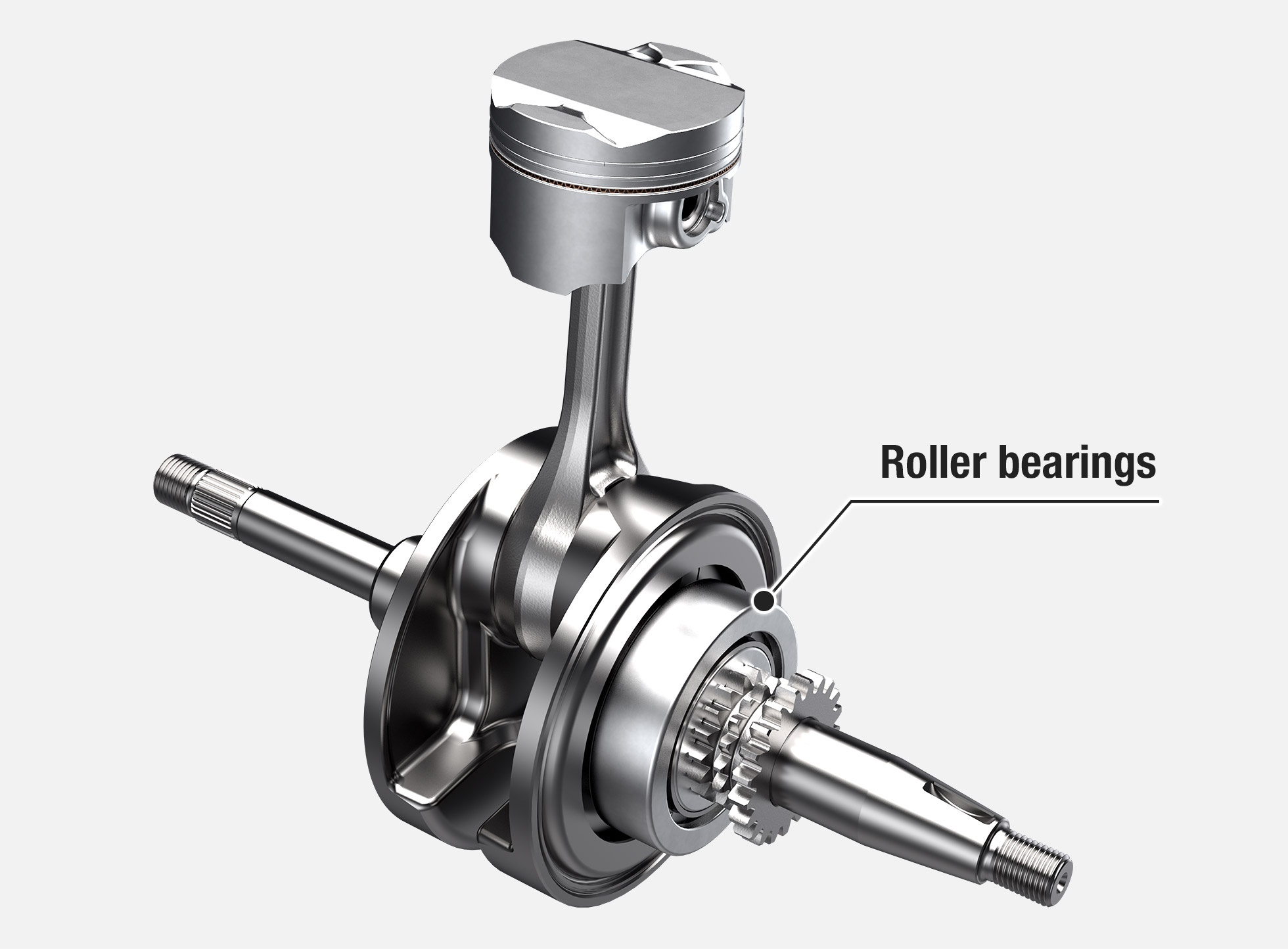

High rigidity around the crankshaft

The crankshaft has been newly designed to improve rigidity. Roller bearings are used for the right side of the crank. This prevents the crankshaft from deflecting due to inertia and combustion energy at high rpm, resulting in increased power output and reduced noise and vibration.

Piston oil jet

The piston oil jet, a high power output technology used in the CRF450R and other models, has been adopted. By injecting engine oil on the back side of the piston, it efficiently cools the piston and suppresses abnormal combustion such as knocking, while allowing the ignition timing to advance, which contributes to increased power output.

In addition to the friction-reducing technologies used in the past, such as roller rocker arms, offset cylinders, and spiny sleeves, many new technologies have been adopted to evolve fuel-efficient performance.

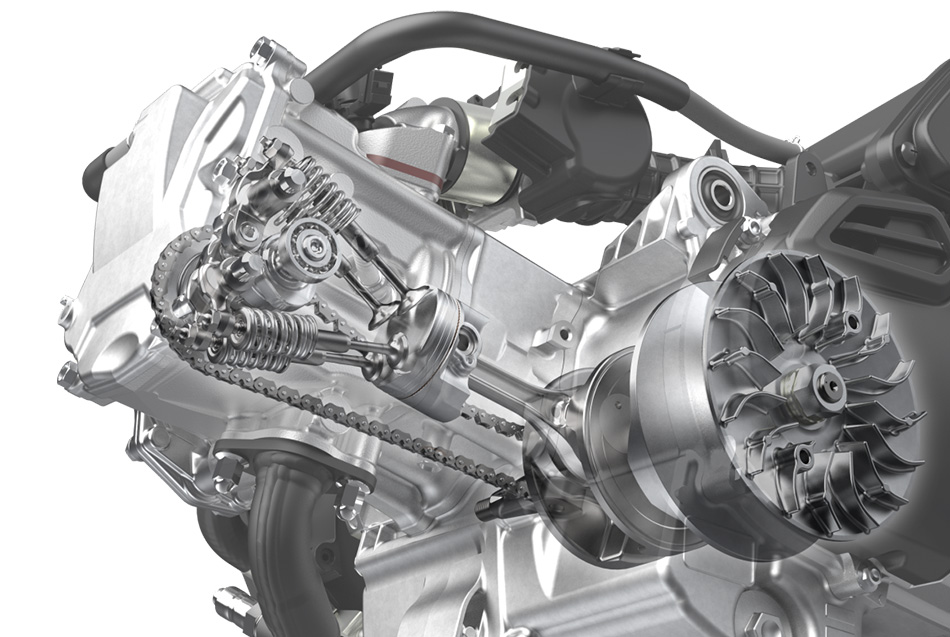

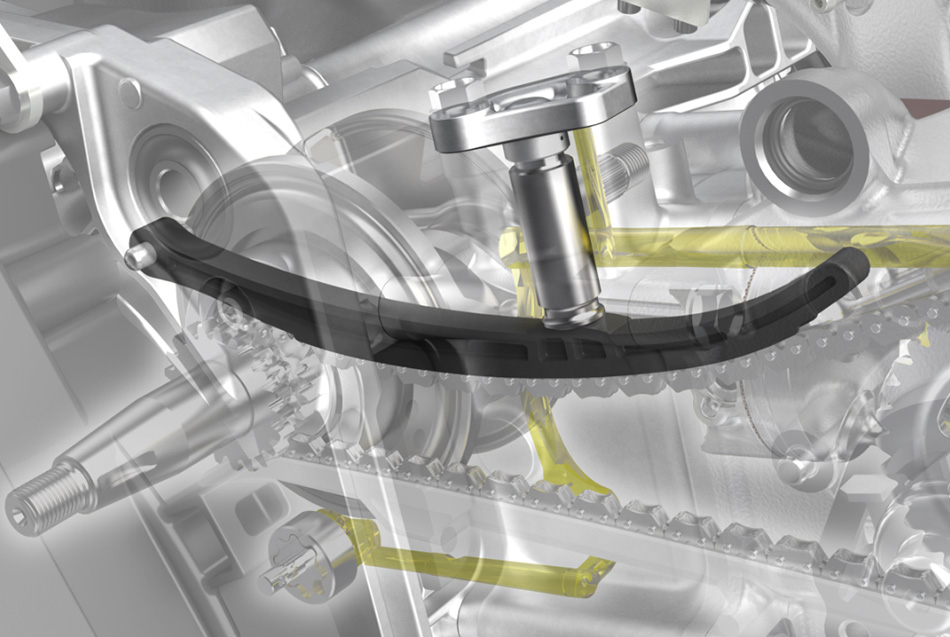

Hydraulic cam chain tensioner lifter

A hydraulic cam chain tensioner lifter has been adopted to apply tension to the cam chain. The hydraulic tensioner lifter suppresses the "swing" of the cam chain as it rotates and reduces friction by allowing the tensioner to follow the chain quickly. This also reduces noise and vibration and improves fuel efficiency compared to conventional models.

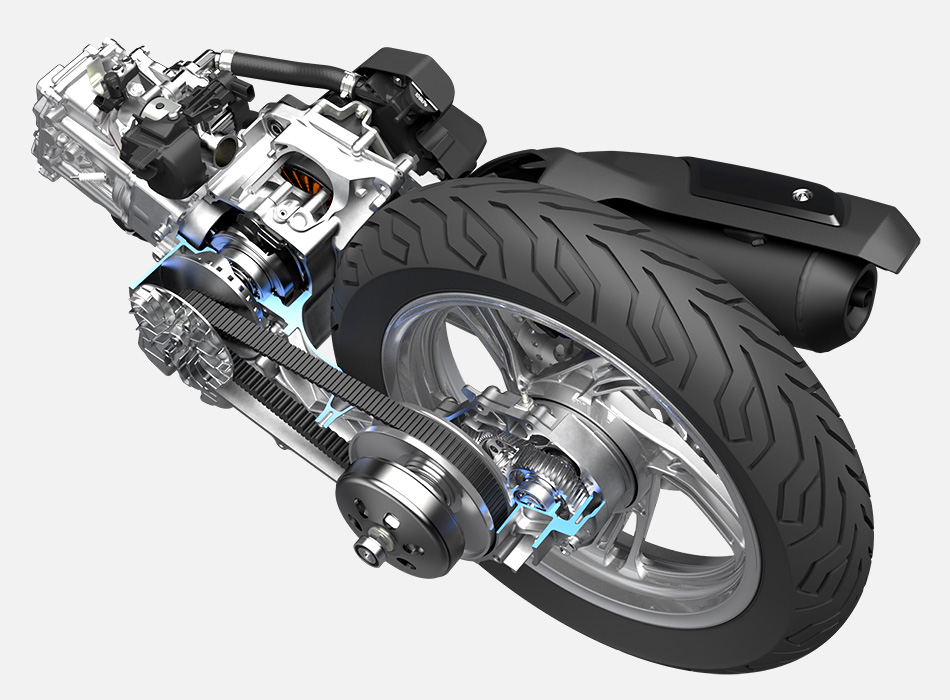

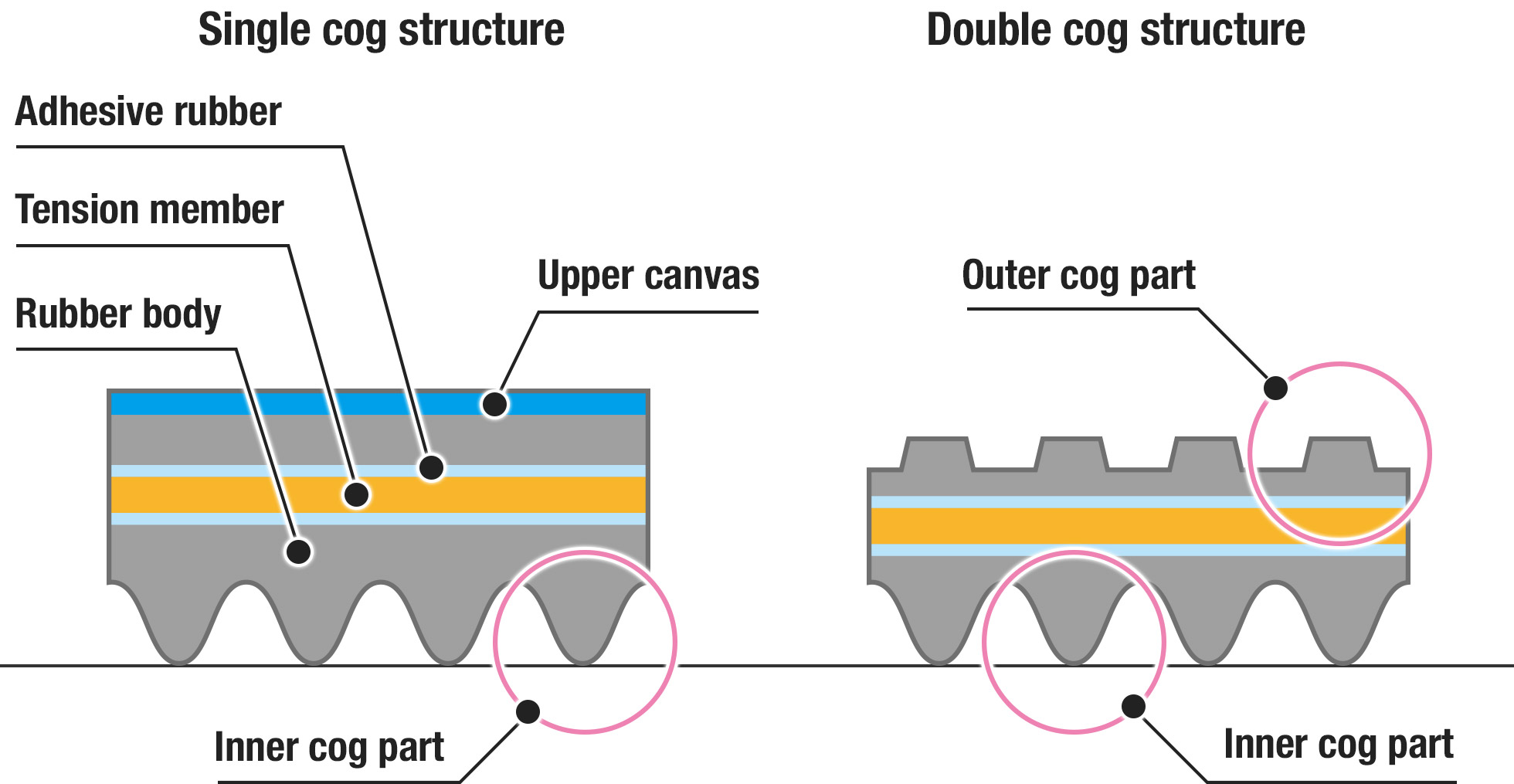

Double cog belt

The drive belt used for shifting gears is a double cog belt with cogs on both the outside and inside. Compared to the single cog structure, the double cog belt is softer in the direction of bending and has higher rigidity against pressure from the sides. This characteristic reduces the resistance generated while bending and suppresses friction. The deformation caused by the pressure applied from the pulleys to the sides of the belt is suppressed, resulting in highly efficient output transmission with less loss of driving force, and low fuel consumption.

Previous control flow

Control flow of the 2020 CRF1100L Africa Twin

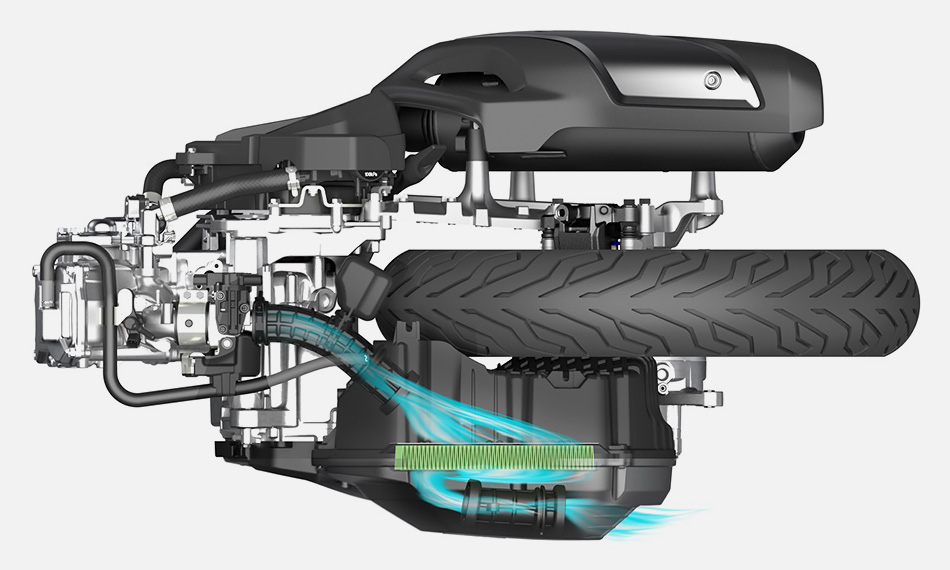

Air intake system

The air intake path of each component from the air cleaner to the inlet pipe has been expanded. By connecting them smoothly, we have improved the intake efficiency. By expanding the capacity of the air cleaner, it contributes to higher power output.

Exhaust system

The pipe connecting the expansion chamber inside the muffler has been straightened to reduce exhaust resistance and achieve powerful driving performance. The placement of the catalyzer has also been optimized to improve the exhaust gas purification performance.

eSP+ Product sites

■Japan & Asia Oceania> Indonesia> Thailand> Vietnam> Malaysia> Japan

■America> United States of America